Makhana roasting has shifted from being a small kitchen task to a serious business in Chandigarh. The snack is in demand, and that demand is not slowing down. Even startups and small factories now need machines that can roast in bulk, maintain quality, and keep hygiene standards high. If you are thinking about starting a roasted makhana machine in Chandigarh, you will need the right machine, a practical setup, and a clear idea of costs.

Why Chandigarh Units Are Choosing Roasted Makhana Machines

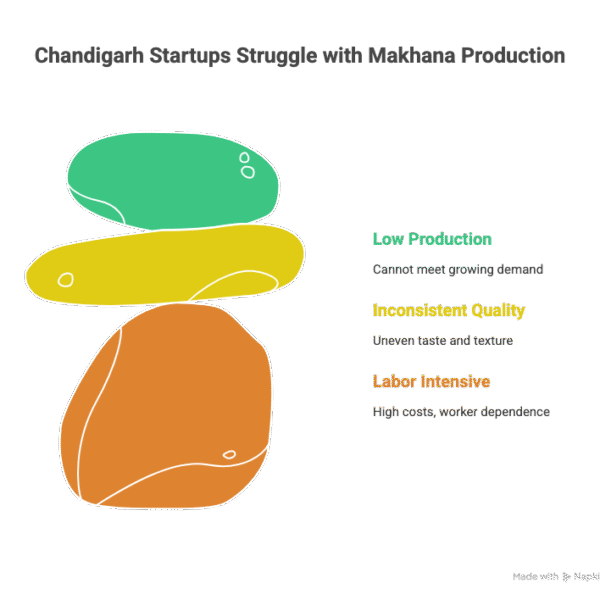

Chandigarh is quickly turning into a space for packaged food startups, and roasted makhana is right at the center of that growth. The demand for makhana is growing fast, but manual roasting has its limits. Here’s why:

- Manual roasting takes a lot of time and money, and you are always dependent on skilled workers.

- Your makhana batches do not always roast evenly, which makes the taste and texture uneven.

- When makhana is roasted manually, the daily production capacity is very low, usually only a few kilos (say 5–10 kg) instead of the hundreds of kilos a machine can handle.

Now, the commercial roasted makhana production plant in Chandigarh solves all these problems.

- The makhana roasting factory in Chandigarh is automatic. So, the laborers do other work, and that saves labor time.

- They deliver uniform roasting, so every batch of makhana tastes and texture looks the same.

- They scale up capacity, letting you move from kilos to hundreds of kilos per day. That helps you grow more demand.

- And most importantly, they give startups and small-scale makhana machines the chance to scale up confidently and meet growing demand.

Complete Plant Setup for Roasted Makhana in Chandigarh

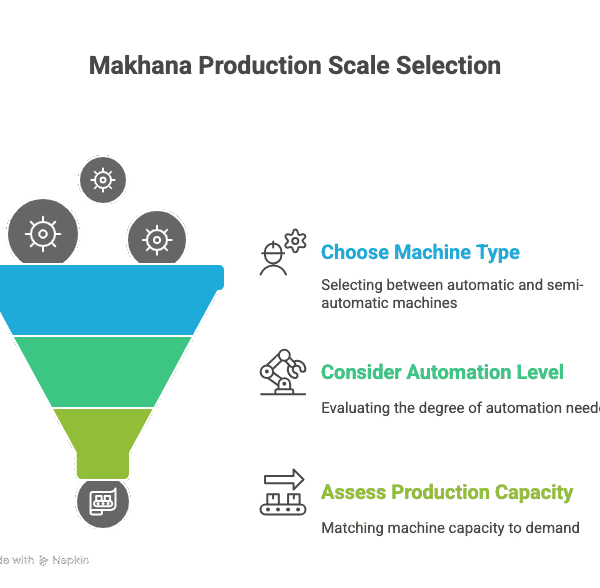

There are two types of industrial roasted makhana machine in Chandigarh. The first one is an automatic roasted makhana machine in Chandigarh, and the second one is a semi-automatic roasted makhana machine in Chandigarh. The choice depends on how much you want to produce. Let’s take a closer look at it.

Fully Automatic Roasted Makhana Plant(Large-Scale Production)

-

Grading

Automatic rotary graders do the heavy lifting here. With automated output measures and a digital display, the machine types makhana into size categories without any manual effort. That means you get a faster throughput and consistent results.

-

Roasting

Large-scale production gives you a uniform roasting with batch after batch. A 22-foot rotating drum and advanced air convection roaster keep the temperature control at 120–130°C, delivering you continuous makhana output without any under-roasting.

-

Coating & Seasoning

A stainless steel drum (10 feet or more)connected with a cutter system handles seasoning evenly across the makhana batch. Slurry kettles and dosing units mix and apply coatings exactly with no stress work and no wastage.

-

Packaging

This is where speed really shows. Automatic nitrogen-flushing packaging machines keep your makhana fresh for longer. There are two options that usually make sense: a Two-head unit, 24–26 pouches per minute, and a four-head unit, 35–40 pouches per minute.

- Material & Hygiene

This automatic roasted makhana machine in Chandigarh has every part made from food-grade stainless steel (304). That is not just about rules, but it also makes cleaning easier and makes sure your product stays safe.

Semi-Automatic Roasted Makhana Plant

-

Grading

A semi-automatic roasted makhana machine in Chandigarh makhana rotary grader, still kinds by size, but it involves some manual work. It gives you an output that is consistent enough for small to medium units without the higher cost of full automation.

-

Roasting

If you are roasting makhana at 30–50 kg per hour, then you do not need a 22-foot drum. Even a medium-capacity roaster and a 48-inch coating pan with hot air circulation do the job well for smaller runs.

-

Coating & Seasoning

For a coating & seasoning, you need a 36-inch flavoring drum. This helps operators to handle the seasoning more directly and gives you the flexibility to experiment with multiple flavor profiles.

-

Packaging

If we talk about the packaging machine, then a semi-automatic nitrogen-flushing units cover the basics. Pouching is stable, though the weighing and sealing may need an operator’s hand. Because it’s slower than the automatic line, but keeps the investment manageable.

-

Material & Hygiene

Like the fully automatic plant, all machinery uses food-grade stainless steel (304). But a little difference is that it’s a mix of manual and automatic steps that keeps costs low while still meeting food safety standards.

Cost & ROI of Roasted Makhana Plant in Chandigarh

The investment in a roasted makhana plant mainly goes into four types of makhana machines, like grader, roaster, coating system, and packaging. Below is a cost comparison of semi-automatic and fully automatic setups. It helps you to choose the best makhana factory setup cost in Chandigarh.

| Machine Type | Capacity (kg/hr) | Approx. Cost (INR) | Key Features | Estimated Daily Output | Estimated ROI Timeline | Ideal For |

| Small Scale | 10–20 | 1.5–3 Lakh | Semi-automatic, stainless steel, energy-efficient heating, manual flavor coating | 100–150 kg/day | 6–8 months | Startups, SHGs, small home-based units |

| Medium Scale | 30–50 | 3.5–6 Lakh | Semi-auto/automatic, precise temperature control, easy cleaning, flavor coating | 300–400 kg/day | 8–12 months | FPOs, regional suppliers, growing businesses |

| Industrial Scale | 100+ | 7–15 Lakh | Fully automatic, continuous operation, integrated packaging, advanced temp control | 800–1,200 kg/day | 12–18 months | Large manufacturers, exporters, commercial units |

Read More: Makhana Machine Cost in India- ROI Analysis for Manufacturers

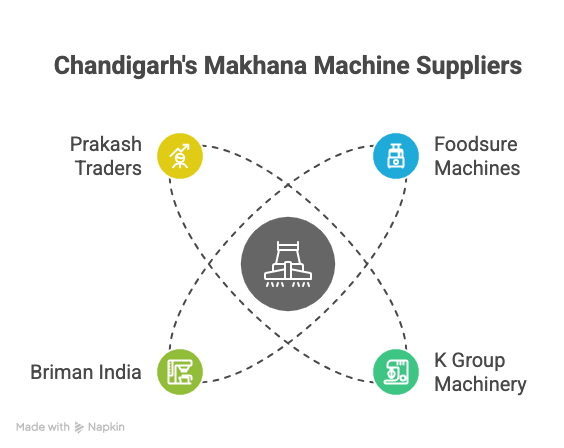

Where to Buy Roasted Makhana Machines in Chandigarh

Selecting the right supplier is the starting point for setting up a makhana processing plant in Chandigarh. Because it shapes how smoothly your unit runs and how stable it grows.

- Foodsure Machines stands out because we do not just sell machines, but we also deliver roasting, grading, and packaging systems that are made to fit your setup. We also provide you a proper installation and dependable after-sales support, so you can see why we earned that trust.

- Startups and large factories across India already work with Foodsure Machines for one reason: because our makhana processing machines give you a consistent quality and the ability to scale without any headaches.

- On the local side, there are suppliers like K Group Machinery, Briman India, and Prakash Traders that provide you a small-scale roasting machines that help beginners get started.

Read More: Top 5 Makhana Machine Companies In India

Ready to Turn Makhana into Your Next Big Business?

With Foodsure Machines, you do not just buy equipment, but you set up a system that is made for scale. Our roasting, grading, and packaging solutions help you keep every batch consistent and efficient. And want to know the real advantage is our hands-on support. We work with startups and growing businesses to fine-tune the roasted makhana production plant in Chandigarh for your needs, so you can actually meet demand instead of chasing it.

Ready to set up your plant?

Get a Free Consultation & ROI Calculator from Foodsure Machines today.

FAQ

Q1. What does a roasted makhana machine cost in Chandigarh?

Small units usually cost you around ₹3–5 lakh. If you are looking at a fully automatic setup for commercial-scale production, the investment can go shift to ₹15 lakh.

Q2. How much can an industrial roasting machine process per hour?

Your output depends on the model, but most machines handle anywhere between 50–200 kilos an hour.

Q5. Where’s the best place to buy a roasted makhana machine in Chandigarh?

Foodsure Machines has set up a strong reputation as a stable supplier. Because we provide full plant solutions and ongoing support.

Q6. How much is a 1kg-capacity Roasted Makhana Machine in Chandigarh?

A 1kg-capacity machine is priced according to build quality and automation level.

Q7. Can a roasting machine handle 100g batches daily?

Yes, all machines easily handle repeated 100g roasting cycles.

Q8. How many makhana pieces can a 1kg roaster process at once?

A 1kg roaster handles roughly 1,500–2,000 pieces per batch.

Q9. Why are roasted makhana machines costly in Chandigarh?

Because they use advanced heating systems and food-grade components.

Q10. How much output does a machine give for a 100g roasting cycle?

It delivers a uniformly roasted 100g batch within minutes.

Q11. In which region near Chandigarh are machines cheaper?

Industrial belts around Mohali and Panchkula often offer lower prices.

Q12. How much time does a machine take to roast 20g of makhana?

It completes a 20g roast in seconds.