In Pune, 7 out of 10 small FPOs still roast makhana manually, losing up to 30% of potential output—despite market demand soaring 112% in 3 years. Small units roast 25–50 kg/day, while industrial machines now handle 100+ kg per batch. So, how do you pick a machine that triples output without burning your budget? If you’re struggling with inconsistent roasting, high energy bills, or downtime, the right commercial roasted makhana machine can fix all of it. This guide breaks down how Pune-based processors can choose a machine that delivers cleaner roasting, lower running cost, faster setup, and reliable local support, so you start strong from day one.

4 Shocking Reasons Pune FPOs Lose 30% of Roasted Makhana Profits

The Pune FPO was getting inconsistent roasted makhana because everything was done manually. Manual roasting cost Pune FPOs 25–30% of potential daily output. They couldn’t scale beyond 50 kg/day due to outdated heating systems. Investing in a roasted makhana machine solved these problems and boosted output 3X.

- Manual roasting ate up time and labor, which kept production low.

- Inefficient heating systems pushed energy costs higher, cutting into profits.

- What this really meant was they couldn’t scale or meet growing market demand.

- Investing in a roasted makhana machine in Pune became essential to improve quality, reduce costs, and stabilize production.

Best Roasted Makhana Machine in Pune: Boost Output 3X with Energy Efficiency

When you are looking for a food processing machine manufacturer in pune, local suppliers don’t all offer the same quality or features. Some stand out by providing a commercial roasted makhana machine Pune that roasts consistently, uses energy efficiently, and comes with stable after-sales support. That support matters because even the best roasted makhana production equipment isn’t much use if it’s still waiting for parts or service.

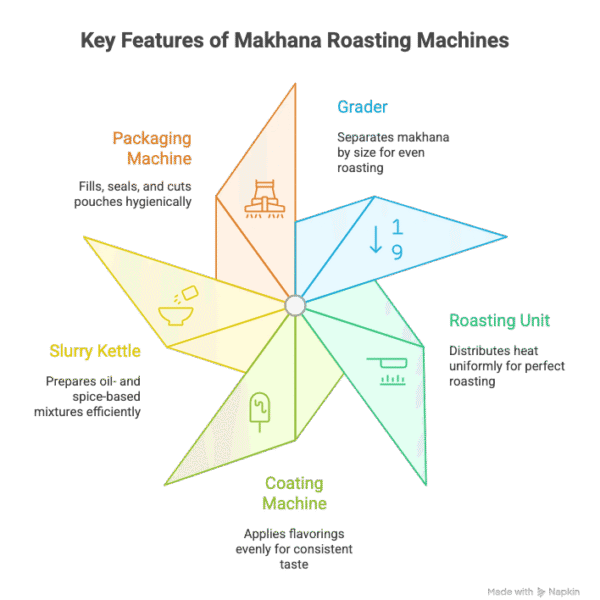

Let’s break down the key features of an Industrial makhana roasting machine and why they matter:

- Grader: The Grader separates makhana by size, perfect for batches from 25–100 kg/day.

- Roasting Unit: A stainless steel drum distributes heat uniformly using electric, gas, and diesel systems. This unit makes sure your makhana roasts perfectly without burning.

- Coating Machine: The coating machine applies flavorings, spices, and coatings evenly over your roasted makhana and giving each batch a consistent taste.

- Slurry Kettle: A kettle helps to prepare oil- and spice-based mixtures and applies them efficiently to improve flavor and texture.

- Packaging Machine: Makhana packaging machine comes in two types: two-head and four-head units, which help to fill, seal, and cut pouches at 30–60 packs per minute. This keeps your process hygienic and safe.

What this really means is that the right roasted makhana production equipment doesn’t just roast makhana. It smooths out your entire production line, from sorting to packaging, and reduces manual work, so every batch meets your quality standards without extra effort.

Read More: Why Upgrading To A Fully Automatic Makhana Line Can Boost Your Output by 3X?

Step-by-Step Pune Setup Guide: Roasted Makhana Machine Running in Hours

Pre-Installation Checklist

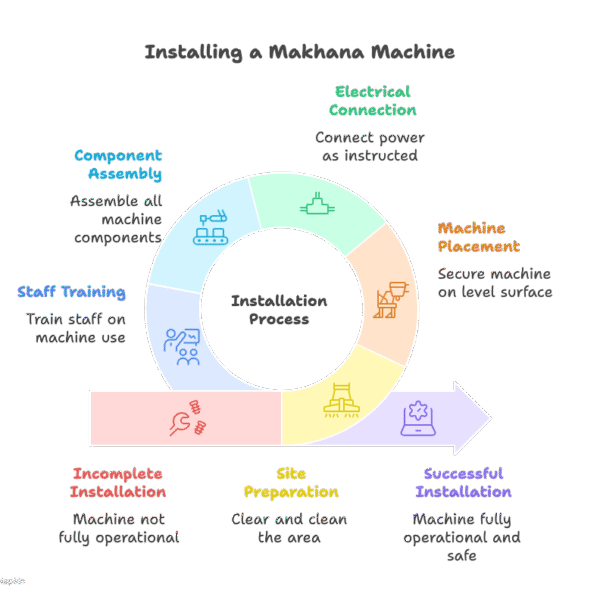

Before you bring a high-capacity roasted makhana equipment into your factory, you need the basics in place. Make sure there is enough space for your machine. Also, check that your power supply is stable and meets the machine’s voltage and current requirements. Because safety is not optional. It’s about the proper grounding and fire protection keep your team safe and your production running smoothly and safely.

Installation Process

-

Site Preparation:

Here’s the thing: clear and clean the area where the energy-efficient makhana roasting machine will go. Make sure power, air supply, and other utilities are ready and working.

-

Machine Placement:

Set the energy-efficient makhana roasting machine on a level surface and secure it. Taking care of vibrations now prevents problems down the line.

-

Electrical Connection:

Connect the power exactly as the makhana manufacturers in pune instructs. Double-check wiring and grounding to avoid any risks.

-

Component Assembly:

Assemble all parts, graders, roasters, coating units, mixture kettles, and packaging machines. Everything should fit smoothly and operate as intended.

Staff Training & First Batch

Your team needs to know the high-capacity roasted makhana equipment inside out. Train them on production, safety, cleaning, and troubleshooting. Watch the first batch closely, monitor roasting times, and coating consistency. Take notes, adjust settings, and encourage questions. Doing this upfront cuts break time, keeps the industrial makhana making machine in peak condition, and make sure every batch of roasted makhana processing machine meets your quality standards.

Ready to scale production? Request a quote for your roasted makhana machine in Pune today.

Industrial Roasted Makhana Machine in Pune: 3–4X Output, Lower Energy Costs & Rapid ROI

| Parameter | Before Machine | After Machine | Impact |

|---|---|---|---|

| Production Capacity | 50–60 kg/day | 150–200 kg/day | 3–4x increase |

| Roasting Quality | Inconsistent batches, uneven color | Uniform roasting, consistent texture | Better taste & appearance |

| Wastage | 10–15% | 2–3% | Reduced raw material loss |

| Energy Cost | High, due to inefficient heating | Lower, energy-efficient system | Cost savings |

| Labor Requirement | 4–5 operators | 2–3 operators | Less manual intervention |

| ROI (Small Units) | N/A | 8–12 months | Faster payback |

| ROI (Medium Units) | N/A | 6–9 months | Quick recovery & scaling |

Boost output 3–4x and reduce wastage. Speak with our experts and schedule a demo!

Limited Pune installations available this month — Book Your Machine Today!

A roasted makhana machine in Pune from Foodsure Machines gives you consistent roasting, energy efficiency, and reliable performance. What this really means is you can scale production without sacrificing quality. Whether you’re starting small or running a larger operation, you get expert installation, local support in Pune, and dependable after-sales service. The end result is higher output, lower costs, and the confidence to meet growing demand with ease. Get your high-capacity roasted makhana machine in Pune now.

FAQ

Q1: What is the ideal capacity for a Pune FPO?

Here’s the thing: for most small to medium operations, 25–100 kg per batch hits the sweet spot. It’s enough to meet demand without overinvesting.

Q2: How much does installation cost locally?

The installation cost depends on the machine and setup; installation usually runs ₹15,000 to₹50,000, covering setup and staff training.

Q3: Which suppliers offer training and support?

What this really means is you want a supplier like Foodsure Machines that offers on-site training, calibration, and local support in Pune.

Q4: How much energy does a commercial roasted makhana machine consume?

Energy use changes, but most industrial units take around 5–15 kWh per 100 kg batch, depending on the heating system.

Q5. What is the cost of a Roasted Makhana Machine in Pune?

It ranges from ₹1.5 lakh to ₹10 lakh depending on capacity.

Q6. Is a roasted makhana machine profitable for Pune businesses?

Yes, high demand and good margins make it highly profitable.

Q7. Which company offers the best roasted makhana machine in Pune?

Foodsure Machines is one of the leading and reliable suppliers.

Q8. How do I start a roasted makhana processing unit in Pune?

Buy the machine, get required licenses, set up roasting space, and start sourcing makhana.

Q9. How much roasted makhana can the machine process per hour?

Most machines process 20–200 kg per hour.

Q10. What is the price of small roasted makhana machines in Pune?

Small units start at around ₹1.5–₹2.5 lakh.

Q11. Which Pune areas have high demand for roasted makhana production?

Bhosari, Pimpri-Chinchwad, and Chakan industrial zones.

Q12. Is roasted makhana better than raw makhana?

Yes, roasted makhana has higher market demand and value.