Missed deadlines, rising product rejection, and constant labour coordination are initiall signs that growth is breaking your system. Why semi-automatic makhana machines fail is not because they stop working, but because they were never designed for scale. However, once orders scale, their hidden limits lead to output inconsistency, dependency on skilled labour, and process bottlenecks that quietly harm profitability and reliability.

Why Semi-Automatic Makhana Machines Struggle as Makhana Production Scales

Semi-automatic makhana machines for processing are usually the first choice for startups, farmer-producer organisations (FPOs), and village-level units. Initially, the maximum output is not the primary goal, but rather learning the process, testing market demand, and managing cash flow. These makhana making machines are perfectly suited to this situation. However, why semi-automatic makhana machines fail becomes clear only when production demand rises.

- Lower upfront cost: They enable business owners to start with the makhana trade without investing in expensive automation that may not justify itself until sales are assured.

- Easy handling: The majority of processes remain under the operator’s control, resulting in easier training in areas where skilled technicians are scarce.

- Best for small batches: Production runs that are small and under control can help to experiment with roasting time, grading quality, and seasoning without the risk of major rejections.

What Changes Inside a Makhana Processing Unit as Output Increases

Scaling up a makhana unit not only puts a strain on the machine but also on the whole process. Founders often face numerous orders at the startup stage. At this stage, the order size increases significantly, typically by 2-3 times, while customers still expect the same consistency. This is where founders start experiencing why semi-automatic makhana machines fail under pressure.

- Larger batch commitments: One delayed batch now affects multiple buyers, not only one shipment.

- Tighter delivery windows: The retail and distributor timelines provide almost no space for manual corrections or rework.

- Stricter quality benchmarks: No rejection is allowed anymore; uniform roasting and grading become mandatory.

- Rising labour dependency: Increased manpower is required to keep up the speed, which results in higher fatigue, errors, and coordination risk.

6 Reasons Semi-Automatic Makhana Machines Fail as Makhana Production Scales

The increasing demand leads to the situation where semi-automatic makhana processing machines are having a hard time; not that they stop functioning, but the surrounding processes cannot accommodate the machines. This is the most practical explanation of why semi-automatic makhana machines fail in real factories.

Manual Dependency Breaks Output Consistency (makhana processing capacity issues)

- Output is greatly dependent on the individual operator’s skill, which is not the same for different shifts.

- The operators become tired during the long hours of production, leading to uneven roasting and slower movements.

- The daily output is different, making production planning difficult.

Batch Processing Creates Hidden Production Bottlenecks

- Every batch is waiting for the one before it to finish, thus creating dead time.

- Loading and unloading activities take up the time span of productive hours without giving any output.

- The dispatch schedules get delayed as the volume increases.

Heat Control Variations Increase Rejection (product rejection in makhana processing)

- Manual heat adjustment leads to roasting or under-roasting on a large scale.

- Peak production does not result in yield but instead increases wastage.

- There is an increase in the number of quality complaints as consistency decreases.

Labour Cost Scales Faster Than Output

- The hiring won’t bring about a proportional growth in capacity.

- Training gaps cause mistakes and slow down production.

- The availability of the workforce turns into a risk for production during peak times.

Maintenance Downtime Hits Hard During Peak Demand

- The semi-automatic systems require frequent stoppages for cleaning and adjustment.

- A single fault can bring the entire line down with no alternative.

Compliance & Uniformity Become Harder to Maintain (Makhana Quality Consistency)

- The level of manual handling determines the changes in food safety monitoring.

- It becomes hard to maintain uniform size, texture, and roast level at higher volumes.

Also read: Top Semi-Automatic Makhana Flavoring Machine | Boost Output

The Real Cost of Delaying an Upgrade in a Makhana Processing Unit

Founders are often the ones who postpone upgrades just to be able to “extract the full value” from the current installations. However, this postponement quietly leads to increased losses throughout the system. When the volume of products increases, the makhana processing capacity concerns first appear in the form of higher rejection, not very dramatically, but steadily. The 3-5% rise is not so much, but it quickly accumulates on a large scale.

The order processors are often unable to fulfil the entire order, resulting in partial shipments or missed dispatches. Over time, customers lower their expectations or, worse still, switch to new suppliers. The largest impact is on reputation: once the unit is regarded as unreliable in terms of quality or timely delivery, price negotiations become tense.

| Cost Factor | Before Scale | After Scale (No Upgrade) |

| Rejection % | 4–6% | 10–14% |

| Labour per kg | Low | High |

| Output consistency | Stable | Unpredictable |

| Cost per kg | Controlled | Inflated |

The Turning Point – When Makhana Processing Needs a Process Change

The turning point for most founders is very clear when the production pressure reaches its peak. It is at this point that they first consult Foodsure Machines, not for a larger unit, but to determine the reason behind the system feeling under pressure, even with the industrial makhana machines running continuously throughout the day. The talk goes from equipment to process at this point.

- Process evaluation: All steps, including roasting, grading, cooling, and handling, are outlined so that the leakage of output in terms of time, heat, or labour can be identified.

- Capacity planning: We are not looking at current demand, but at what the realistic requirement will be in the next 6-12 months.

- Bottleneck identification: Instead of blindly adding more machines, we pinpoint the precise stage that is causing the slowdowns.

- Machine–growth alignment: We ensure that the output capability aligns with order commitments, not just peak-hour assumptions.

When Is the Right Time to Upgrade Your Semi-Automatic Makhana Machine?

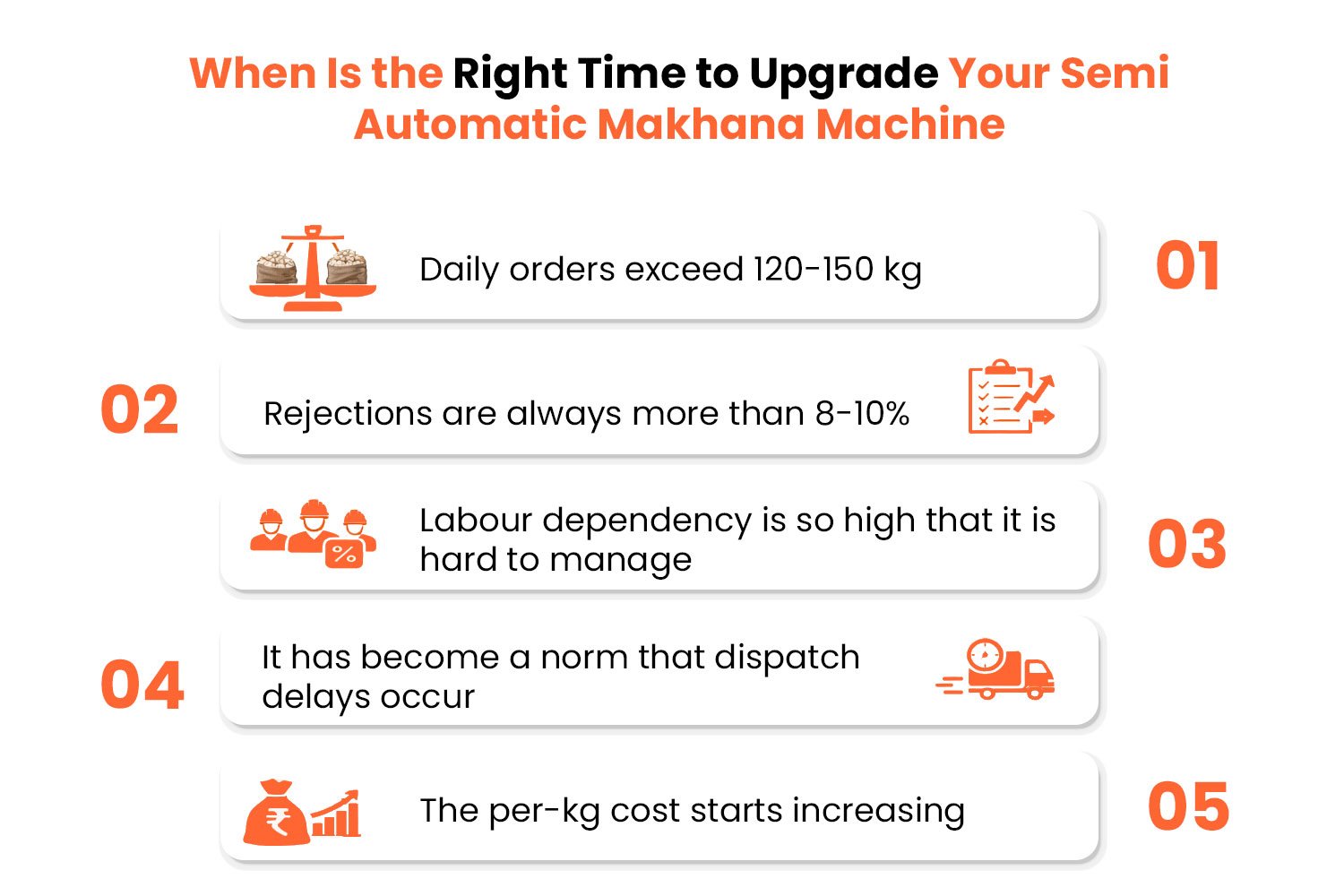

If you doubt that it is the right time, this checklist generally brings founders to clarity:

- Daily orders exceed 120-150 kg: Although the machine may still be running, the batch cycles occupy the entire day and consume the buffer time.

- Rejections are always more than 8-10%: With low volume, small quality losses can turn into larger margin leaks at scale.

- Labour dependency is so high that it is hard to manage: The output is now determined by the person on duty rather than by a predictable process.

- It has become a norm that dispatch delays occur: Production and delivery timelines are not in sync, resulting in missed or partial shipments.

- The per-kg cost starts increasing: Even if there are no higher raw material prices, costs are inflated due to labour, rework, and downtime.

Conclusion

Semi-automatic makhana machines won’t just suddenly stop working, but the limitations of their capacity will become apparent. Foodsure Machines emphasises finding the exact point where your process fails. We will help you double your production while maintaining a clear, consistent, and properly automated process, rather than relying on trial and error.

FAQ

Why do semi-automatic machines struggle with large orders?

They rely on people, and people aren’t perfectly consistent when the workload jumps.

Can these machines maintain quality at higher volumes?

Not really. Bigger batches make even roasting and grading almost impossible.

Do labour costs rise with semi-automatic machines?

Yes. More hands are needed to keep pace, and costs climb faster than output.

Are batch processes a bottleneck?

Absolutely. Each batch waits for the last, and the whole line slows down.

How does manual heat control affect output?

It’s hit or miss. Too hot or too cold, and rejection rates spike.

Do semi-automatic machines break often?

Not usually. The problem is downtime for cleaning and adjustments, which eats into production.

When should a machine upgrade be considered?

If daily orders cross 120–150 kg or rejection hits 8–10 per cent, it’s time to rethink.

How does scale impact compliance and uniformity?

Manual handling makes it tough to maintain size, texture, and food safety at scale.

Is training a big factor in machine efficiency?

Very much. Gaps in skill show up immediately in both output and quality.

Does scaling without an upgrade affect costs?

Yes. Hidden labour, rework, and delays push per-kilogram costs higher than expected.

Can semi-automatic machines handle peak demand?

Not reliably. They keep running, but dispatch slips and stress builds quickly.

What’s the main hidden risk of delaying an upgrade?

Your reputation takes a hit before you notice quality drops and deliveries slip.