If you want consistent, premium-quality roasted makhana, your roasting process must be accurate, fast, and uniform. The Roasted Makhana Machine in Gurgaon is designed exactly for this, it controls heat precisely, maintains flavour, and preserves nutrients in every batch. Whether you’re a small startup or a large-scale unit, the machine handles both small and bulk production smoothly, ensuring your makhana looks better, tastes better, and sells better.

Why Startups and Large Units Need a Reliable Roasted Makhana Machine

Startups and large-scale units benefit a lot from having a dependable roasted makhana machine. Let’s break it down.

For startups:

- A consistent machine means every batch comes out right, helping to make a strong reputation without wasting time or effort.

- Less manual work cuts operational costs and keeps production moving smoothly.

- Accurate temperature control maintains nutrients and gives the crunch customers expect.

For large-scale units:

- Machines need to run continuously and handle high volumes without frequent breaks.

- Solid construction, smart automation, and energy-efficient operation keep production steady.

- Food-grade stainless steel guarantees hygiene and meets safety standards, ensuring compliance is easier.

For all businesses:

- Dependable machines reduce non-productive time thanks to a long-lasting design and local support for maintenance and service parts.

- Scalable options let you expand capacity as your demand grows.

- A good roasted makhana machine in Gurgaon improves consistency, keeps your production smooth, and enhances profitability in a market that keeps getting more competitive.

Key Challenges in Roasted Makhana Production

The roasted makhana machine in Gurgaon has high growth demand, but it comes with some real challenges. Let’s break them down.

Keeping the roast consistent:

- Uneven roasting changes the taste, texture, and overall quality. Customers notice, and trust can slip fast.

- Commercial makhana roasting equipment needs effective heat distribution, even if that’s hot air circulation or a rotating drum design.

- Continuous mixing ensures every piece gets the same even heat contact, so each batch comes out just right.

Scaling production without losing quality:

- Startups often run into production slowdowns when trying to increase output because machines or process controls can’t keep up.

- Larger units need high-capacity machines that handle big batches without compromising consistency.

- Equipment made for scalability keeps products uniform, no matter how fast you grow.

Meeting hygiene and safety standards:

- Roasted makhana is ready-to-eat, so following FSSAI or ISO norms is very important for the food business.

- Food-grade stainless steel makes your machines easier to clean.

- Temperature-controlled roasting keeps your product safe, avoiding burning.

The right roasted makhana machine in Gurgaon does more than just roast by protecting product quality, guaranteeing safety, and keeping customers coming back.

Must-Have Features of a Roasted Makhana Machine in Gurgaon

Selecting the right roasted makhana machine in Gurgaon is not just about picking the biggest or most expensive option. It’s about the production capacity, automation, and other factors.

Production capacity:

- Pick an industrial roasted makhana machine that meets today’s needs but can grow with you.

- Startups often do well with 25–50 kg/hr machines.

- Larger production needs 100 kg/hr or more to keep up with rising demand without constant capacity expansion.

Automation:

- Semi-automatic machines fit startups because they are easy to use and keep labor costs in check.

- Fully automatic systems are better for large units. Because they combine feeding systems, temperature controls, and automatic discharge, they keep output consistent and reduce manual work.

Energy efficiency:

- A roasted makhana processing machine that uses electricity saves money over time, especially for continuous roasting.

- Energy-efficient makhana roasting machines is a good insulation and optimized heating reduce energy loss and cut costs, which adds up fast.

Maintenance:

- Look for a roasted makhana processing machine that is easy to clean and service.

- Modular parts and clear maintenance guidelines reduce non-productive time and keep your production smooth.

Roasting technology:

- Hot air roasting circulates heat evenly.

- Mixer-equipped machines move the makhana constantly to avoid burning and guarantee a uniform roast.

- Advanced hot-air systems combine both techniques for the best texture and flavor preservation.

That means each choice of capacity, automation, maintenance, and roasting method affects your product quality, consistency, and efficiency.

Roasted Makhana Machine Specification & Price Comparison for Startups & Large Units

| Feature | Small-Scale Startup Machine | Medium Unit Machine | Large-Scale Industrial Machine |

|---|---|---|---|

| Capacity (kg/hr) | 10–20 | 50–100 | 150–250 |

| Power Consumption | 3–5 kW | 10–15 kW | 20–30 kW |

| Automation | Semi-automatic | Automatic | Fully Automatic |

| Roasting Method | Hot air | Hot air + stirrer | Hot air + advanced stirring |

| Maintenance | Easy | Moderate | Skilled maintenance required |

| Price Range (INR) | 1–3 Lakh | 5–10 Lakh | 15–25 Lakh |

| Ideal For | Startups / FPOs | Medium-scale units | Large commercial units |

Request a Free Quote Today and Upgrade Your Production Efficiency!

Trusted Roasted Makhana Machine Suppliers & Dealers in Gurgaon

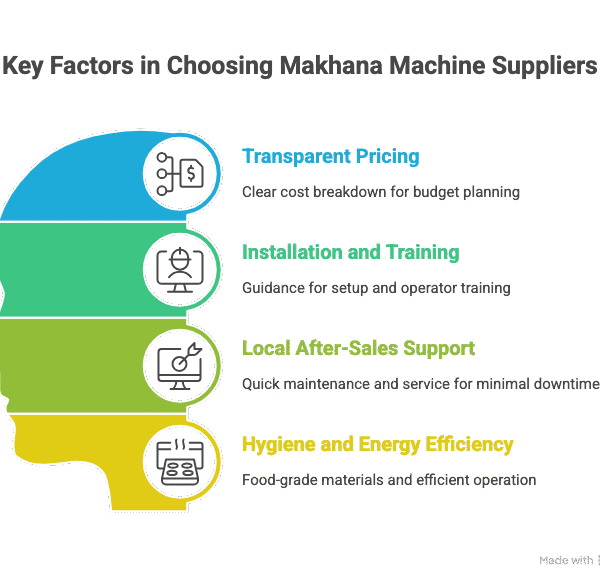

Choosing the right supplier for a roasted makhana machine in Gurgaon can make or break your production setup. Let’s break it down.

Transparent pricing:

- You know exactly what your investment covers, with no hidden costs.

- This clarity helps startups and large units plan budgets confidently.

Installation and training:

- Suppliers guide you through the setup and train operators properly.

- Well-trained operators reduce mistakes, run machines efficiently, and extend equipment lifespan.

Local after-sales support:

- Dedicated teams handle maintenance, troubleshooting, and service parts quickly.

- Fast service keeps non-productive time minimal, so production doesn’t stop.

- Service contracts can be customized to fit your operation and growth plans.

Hygiene and energy efficiency:

- The top roasted makhana machine are made from food-grade stainless steel and designed to operate efficiently.

- This ensures safe, clean production, regardless of even if you are a small startup or a large industrial unit.

What this really means is that picking the right supplier isn’t just about the top roasted makhana machine. It’s about getting a partner who supports your business, keeps operations smooth, and helps you maximize your investment.

Makhana Factory Setup Cost Explained: From Parts to Price

| Feature | Small-Scale Startup Machine | Medium Unit Machine | Large-Scale Industrial Machine |

|---|---|---|---|

| Heating Chamber Cost (INR) | 30,000–50,000 | 80,000–1.5 Lakh | 3–5 Lakh |

| Stirring Mechanism Cost (INR) | 20,000–40,000 | 50,000–80,000 | 2–3 Lakh |

| Control Panel Cost (INR) | 15,000–25,000 | 30,000–50,000 | 1–2 Lakh |

| Frame & Casing Cost (INR) | 20,000–35,000 | 50,000–1 Lakh | 2–4 Lakh |

| Conveyor / Feeding System Cost (INR) | N/A | 50,000–80,000 | 1–2 Lakh |

| Safety & Sensors Cost (INR) | N/A | N/A | 50,000–1 Lakh |

| Automation | Semi-automatic | Automatic | Fully automatic |

| Roasting Method | Hot air | Hot air + stirrer | Hot air + advanced stirring |

Ready to Invest in a Roasted Makhana Machine?

A dependable roasted makhana machine keeps production consistent, maintains quality, and helps you make the most of every batch. Foodsure Machines in Gurgaon offers solutions that match different capacities and energy needs, with an industrial roasted makhana machine designed for easy operation and proper hygiene. You don’t just get equipment, you get support that keeps your production consistent, your product premium-quality, and your business ready to meet growing demand.

🚀 Take the First Step to Higher Output!

Get Your Quote – Connect with us instantly.

FAQ

Q1. What is the best roasted makhana machine for startups in Gurgaon?

For a small startup, semi-automatic machines a best with a 10–20 kg/hr capacity make the most sense. They are easy to operate and deliver consistent roasting without needing a large workforce.

Q2. How much does a commercial roasted makhana machine cost?

Costs range from about ₹1 Lakh for small semi-automatic units to ₹25 Lakh for high-capacity, fully automatic industrial machines. The machine price depends on your production needs, the level of automation, and the specific features each machine offers.

Q3. Can large-scale units scale production efficiently with these machines?

Yes. Industrial machines with 150–250 kg/hr capacity are made for high-volume production without sacrificing quality. They run continuously and make scaling up a smooth process.

Q4. How do I start a roasted makhana unit with a machine in Gurgaon?

By selecting the right roasting machine, licenses, and raw materials locally.

Q5. How long does a roasted makhana machine take to roast one batch?

Most machines roast makhana in 3–7 minutes per batch.

Q6. Can roasted makhana machines produce daily-consumption quality snacks?

Yes, they deliver consistently healthy, oil-controlled roasted makhana.

Q7. Which oil works best with a roasted makhana machine?

Olive, rice bran, or cold-pressed oils work best for machine roasting.

Q8. Does a roasted makhana machine give better results than raw processing?

Yes, roasting machines offer better texture, taste, and shelf life.

Q10. How long can machine-roasted makhana stay fresh?

Typically 45–90 days with proper flavoring and packaging.

Q11. Can a roasted makhana machine reduce wastage?

Yes, automated heating ensures uniform roasting with minimal burn loss.

Q12. How much protein remains after machine roasting?

About 9–12g protein per 100g, depending on the seed quality.