Post-pandemic consumer behavior has permanently shifted. Consumer behavior has shifted permanently. Nutrition is no longer aspirational, it’s foundational. Protein-enriched foods, supplements, and functional snacks are now essential, not niche.

For manufacturers, this creates massive opportunity, but also operational pressure: manual processes can’t keep up with scale, consistency, or compliance. Enter the Protein Premix Machine. It’s not just equipment, it’s a strategic asset that ensures precision, efficiency, and hygiene in protein food processing machinery.

What Is a Protein Premix?

A Protein Premix Machine is an industrial mixer designed to:

- Accurately dose powders and micro-ingredients.

- Uniformly blend protein, vitamins, and minerals.

- Maintain hygiene and comply with FSSAI/GMP standards.

Applications include:

| Product Type | Typical Use |

|---|---|

| Protein bars | Consistent texture, weight, and nutrient profile |

| Meal replacements | Smooth, lump-free powders |

| Functional bakery items | Precise protein fortification |

| Ready-to-drink powders | Rapid solubility and taste consistency |

| Nutritional snacks & supplements | Batch-to-batch uniformity |

Read More: Protein Powder Blending Machine for Food Factories Delivering 95% Batch Consistency

Why Your Food Production Needs a Protein Premix Machine

High-Quality Products

Manual mixing leads to inconsistency in size, texture, and taste. With a protein bar manufacturing machine:

- Proteins, micronutrients, and functional ingredients blend uniformly.

- Finished products maintain premium quality and compliance.

Greater Production & Scalability

- Semi-automatic machines: under 100 kg/hr (ideal for startups).

- Fully automatic lines: 100–1000 kg/hr (industrial-scale production).

- Easily scale production without compromising quality.

Flexibility Across Protein Types

Supports whey, casein, soy, pea, rice, and mixed protein formulations. Switch recipes or create new product variants without halting the line.

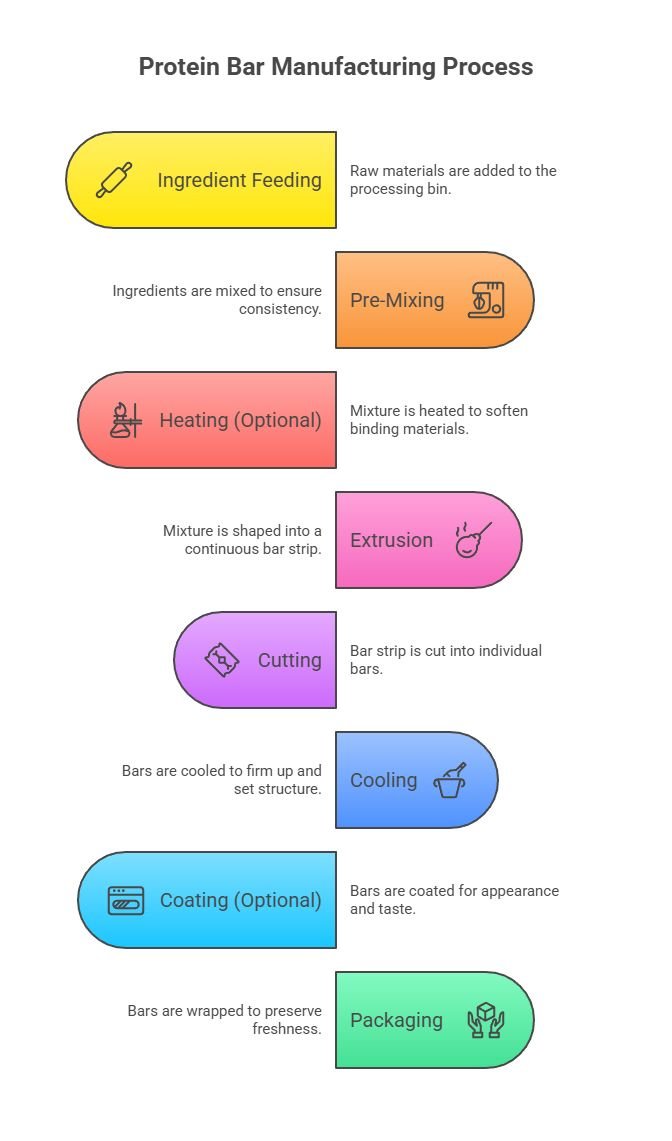

How a Premix Processing Equipment Works: Step-by-Step

| Step | Process | Benefit |

|---|---|---|

| 1 | Ingredient Feeding – automated/manual dosing | Accurate nutrition & consistency |

| 2 | Pre-Mixing – dry blending | Eliminates clumping & segregation |

| 3 | Controlled Heating (optional) | Activates binders, preserves flavor |

| 4 | Extrusion | Ensures density & uniform structure |

| 5 | Precision Cutting | Weight control & packaging-ready |

| 6 | Cooling & Setting | Reduces stickiness, extends shelf life |

| 7 | Coating (optional) | Chocolate, yogurt, or flavored coatings |

| 8 | Hygienic Packaging | Protects against contamination & moisture |

Foodsure Machines Protein Processing Equipment: Specs & Pricing

| Model | Capacity | Automation | Price (₹) | Power | Notes |

|---|---|---|---|---|---|

| Foodsure Machines FS-PM-100 | 100 kg/hr | Semi-automatic | 5,00,000 | 3–4 kW | Ideal for startups |

| Foodsure Machines FS-PM-500 | 500 kg/hr | Fully automatic | 9,50,000 | 5–7 kW | Mid-scale production |

| Foodsure Machines FS-PM-1000 | 1000 kg/hr | Fully automatic | 15,00,000 | 10 kW | Industrial-scale production |

Why Choose Foodsure Machines:

- Designed for precision, hygiene, and high speed.

- Supports all protein types & custom blends.

- Easy recipe adjustments for new product innovation.

- Minimal wastage, consistent output, high ROI.

Benefits and Features of Protein Premix Machines You Should Know

- Protein food processing equipment for premixes eliminate uncertainty when blending protein powders and other ingredients. They provide consistency in the final mix and minimize potential errors that can impact taste, texture, and nutrition.

- They can be used for blends that are whey, casein, plant proteins, or custom blends, so this provides some versatility depending on the product. Because the mixing is designed for high speed, this machine improves overall production, while also eliminating a good deal of labor through the automated system.

- These protein bar machine maintain the hygiene of food and the quality of the products, as the machines can be easily cleaned. They provide effortless options to adjust the controls of the machine, allowing ease of new product innovations and developments.

- Overall, the machines themselves allow for less waste and produce an entire batch with quality in mind, giving consumers peace of mind. Condensed, machines facilitate easier production for nutritious and high-quality products consistently.

Conclusion

A Protein Premix Machine transforms nutrition production from a variable-driven process into a controlled industrial system. It ensures consistency, safety, scalability, and speed, while enabling brands to innovate without operational compromise. If you are serious about competing in the health food and supplement market, manual blending is not a strategy, it’s a liability.

Partner with Foodsure Machines and build a production line that delivers confidence, compliance, and commercial scale.

FAQ

Q1. What is a protein premix machine used for?

It uniformly blends protein powders, vitamins, and micronutrients for consistent nutrition products.

Q2. Is a protein premix machine suitable for whey and plant proteins?

Yes, it handles whey, casein, soy, pea, rice, and mixed protein formulations.

Q3. What is the production capacity of a protein premix machine?

Capacities range from under 100 kg/hr to over 1000 kg/hr depending on automation level.

Q4. Can protein premix machines be used for protein bars and powders?

Yes, they support bars, powders, meal replacements, and functional food products.

Q5. Are protein premix machines fully automatic?

They are available in semi-automatic and fully automatic industrial configurations.

Q6. How does a protein premix machine ensure uniform mixing?

Precision mixing systems eliminate segregation and ensure batch-to-batch consistency.

Q7. Is a protein premix machine compliant with food safety standards?

Yes, when installed in an FSSAI-compliant facility and operated under GMP norms.

Q8. What industries use protein premix machines?

Health foods, sports nutrition, supplements, bakery, and functional food manufacturers.

Q9. How much investment is required for a protein premix machine?

Initial investment typically starts from ₹5 lakh and increases with capacity and automation.

Q10. Is a protein premix machine profitable for manufacturers?

Yes, high demand and scalable production make it a profitable long-term investment.