The India makhana market size reached INR 8.5 Billion in 2024. Looking forward, IMARC Group expects the market to reach INR 19.6 Billion by 2033, exhibiting a growth rate (CAGR) of 9.22% during 2025-2033.When you are making more makhana, the coating is still uneven. Some pieces have too much seasoning and others barely any. You are wasting ingredients, and buyers are starting to notice these problems. The real issue is likely your makhana flavoring drum. If it doesn’t rotate smoothly, if seasoning collects in corners, or if speed and angle are not controlled properly, your batches will keep missing the mark. That means lost product, wasted spice, and buyers who stop coming back.

The right drum keeps the makhana whole, moves each piece at the right pace, and coats everything evenly. No heavy patches, no bare spots, no build-up inside the machine. It also saves ingredients. What you put in ends up where it should: on the product. In this blog, we see how to choose a flavoring drum for roasted makhana that is built to handle real production.

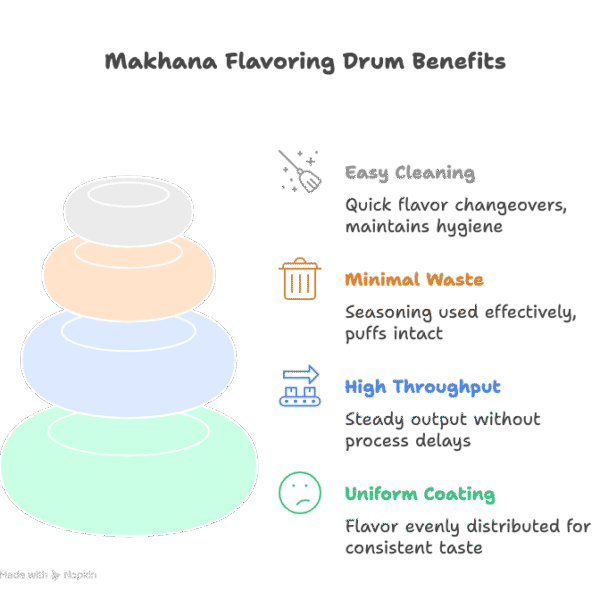

Why You Need The Right Makhana Flavoring Drum

The right automatic makhana machine shapes how your makhana tastes, how much you waste, and how reliably you can grow. It’s not just a piece of equipment; it’s the difference between smooth output and repeating problems. If you are scaling up, this is where things either start working better or start breaking down. So before you invest, focus on what actually matters:

-

Even, Uniform Coating:

Flavor should stick to every piece, not gather in some, but disappear in others. When the coating is uniform, the snack delivers the same taste every time. That’s what brings people back.

-

Higher Throughput Without Holdups:

A well-designed automatic makhana flavoring machine moves in line with the rest of your process. No pileups and no trays waiting. There is just steady, high-speed makhana flavoring machine output without slowing things down.

-

Minimal Waste, Maximum Output:

The seasoning goes where it should on the flavoring drum for roasted makhana, not wasted inside the drum or on the floor. Puffs stay intact, and you get more cleaner, finished product per batch.

-

Easy to Clean, Made for Hygiene:

This is made from SS 304 stainless steel flavoring drum for makhana. Quick cleanouts mean faster changeovers between flavors. You stay compliant, stay clean, and keep the line moving without dragging into downtime.

Makhana Flavoring Drum: Inside The Process

Let’s look inside the automatic makhana flavoring machine and see how it actually shapes your flavor, speed, and consistency.

-

Rotating for Uniform Coating:

When a roasted and graded makhana enters a rotating stainless steel flavoring drum for makhana, that gently tossed each kernel to ensure uniform contact with the seasoning.

-

Step-by-Step Seasoning:

A fine spray of oil or slurry coats the surface first, followed by accurate dosing of dry spices or flavor powders. This layering ensures flavor sticks without lumps or gaps.

-

Controlled Speed:

The high-speed makhana flavoring machine can be tuned to suit your product type and fast enough to scale with gentle enough to keep the makhana whole.

-

Ready for Packing:

Once the makhana is evenly coated, it exits the drum crisp, flavorful, and ready to move. Depending on your setup, it either heads straight to cooling or into packing. Then there is no rework, no waiting just a finished product that’s ready to hit the shelf.

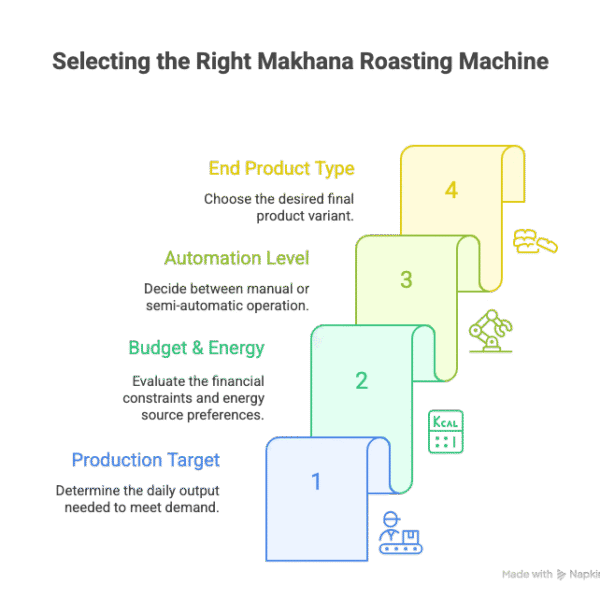

Key Specifications Of Makhana Flavoring Drum

What matters most in an industrial makhana flavoring equipment is the specifications that drive performance and consistency. These details shape how well your makhana processing machine runs and how reliably your product turns out.

| Feature | Specification |

| Capacity | 30–100 kg per batch |

| Drum Size | 700–1000 mm dia × 1200–1500 mm length |

| Power | 1.5–3 kW, 3 Phase, 415V |

| Speed Control | VFD-based adjustable rotation |

| Coating System | Oil/slurry spray + dry spice dosing |

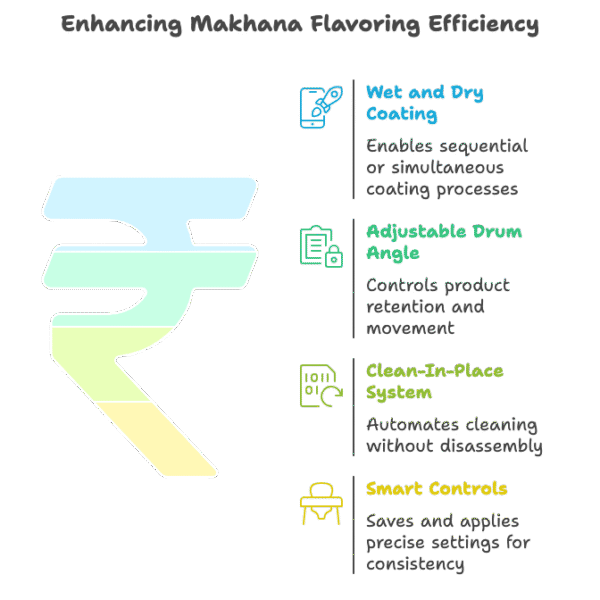

Advanced Features In Modern Makhana Flavoring Drums

If you are scaling up, the basics are not enough. The right features help you coat better, clean faster, and waste less. Let’s take a look at what actually matters.

-

Wet and Dry Coating in One Go

No need for separate machines. The drum handles oil or slurry first, then dry spices either one after the other or together, depending on your recipe. That means fewer transfers, less mess, and better control.

-

Drum Angle That Works With You

When you can adjust the drum’s tilt, you control how long the makhana stays inside. A gentler angle for delicate puffs, or a steeper one when you need faster movement. It’s simple, but it makes a big difference in keeping the product intact.

-

Clean-In-Place Without the Hassle

Nobody wants to break down a machine between every batch. With built-in CIP (Clean-In-Place), you hit a button and the system does the work washing out residue fast and clean, without taking everything apart.

-

Smart Controls That Actually Save Time

Touchscreen controls with PLC let you save exact settings for each flavor. You don’t need to dial things in every time. Just load your recipe and go. Batch after batch stays consistent, and so does your product.

Foodsure Machines: Your Makhana Flavouring Machine For Growth

Foodsure Machines makes it easier to get the right industrial makhana flavoring equipment drum for your setup. Our industrial makhana flavoring equipment drums are made from food-grade stainless steel, built to scale, and designed for even coating with zero waste. This machine also has precision slurry dosing and smart PLC controls; the machines keep your batches consistent and your output high. Cleaning is quick, operation is simple, and their support actually shows up when you need it. If you are growing your makhana production, this is a system that grows with you.

Need the right makhana flavoring drum?

Reach out to us anytime via call or email.

FAQ

1. How does the right flavoring drum ensure even coating when you are scaling up?

A good flavoring drum balances rotation and dosing speed so every makhana gets coated the same way, every time. That’s how you keep batches consistent and buyers happy even when volumes increase.

2. What features actually help reduce waste?

You know that precision dosing, fine mesh filters, and seasoning catch trays make a big difference. They keep ingredients from going to waste, which saves money and keeps your production line cleaner and more efficient.

3. Why does hygienic design matter so much for makhana flavoring machines?

It is because every batch needs to be safe, clean, and quick to turn around. Stainless steel, smooth welds, and easy-access parts help prevent contamination, meet food safety standards, and make cleaning a whole lot faster between batches.

4. How much does a Makhana Flavoring Drum cost?

Prices vary by capacity and automation, generally starting from affordable small-unit models.

5. What flavors can be made in a Makhana Flavoring Drum?

It can coat makhana with any dry or liquid flavoring like cheese, peri-peri, chocolate, or masala.

6. Is a Makhana Flavoring Drum profitable for business?

Yes—because it boosts output, consistency, and flavor quality, improving overall profits.

7. Can I use a Makhana Flavoring Drum daily?

Yes, it’s designed for daily commercial use with continuous operation support.

8. Are makhana made in a flavoring drum healthy?

Yes—health depends on seasoning used, but the drum ensures cleaner, controlled coating.

9. Why is a Makhana Flavoring Drum considered costly?

Its price reflects stainless steel build, automation, and uniform coating technology.

10. Is the Makhana Flavoring Drum suitable for oil-free production?

Yes, it supports low-oil or oil-free flavor coating methods.

11. Which Makhana Flavoring Drum quality is best?

Food-grade stainless steel drums with variable speed control are the best choice.

12. Which city is famous for Makhana Flavoring Drum manufacturing?

Several industrial hubs like Delhi, Kolkata, and Ahmedabad produce high-quality units.