Roasted makhana has gained significant popularity in the fast-changing snack industry due to its health advantages, hence gaining popularity among health-conscious consumers. However, there are various challenges associated with the introduction of the roasted makhana brand. One of the most important choices that any startup should make is the choice of appropriate makhana roasting equipment.

To pick the most vital considerations when deciding to buy a machine that roasts makhana, this high-end guide looks at the aspects that matter the most, including the stability of the roasting process, the oil handling process, and even distributing the seasoning well, making sure that your new business produces its maximum and practically a minimum amount of waste.

Founder Pain: What Goes Wrong After Buying “Any Machine”

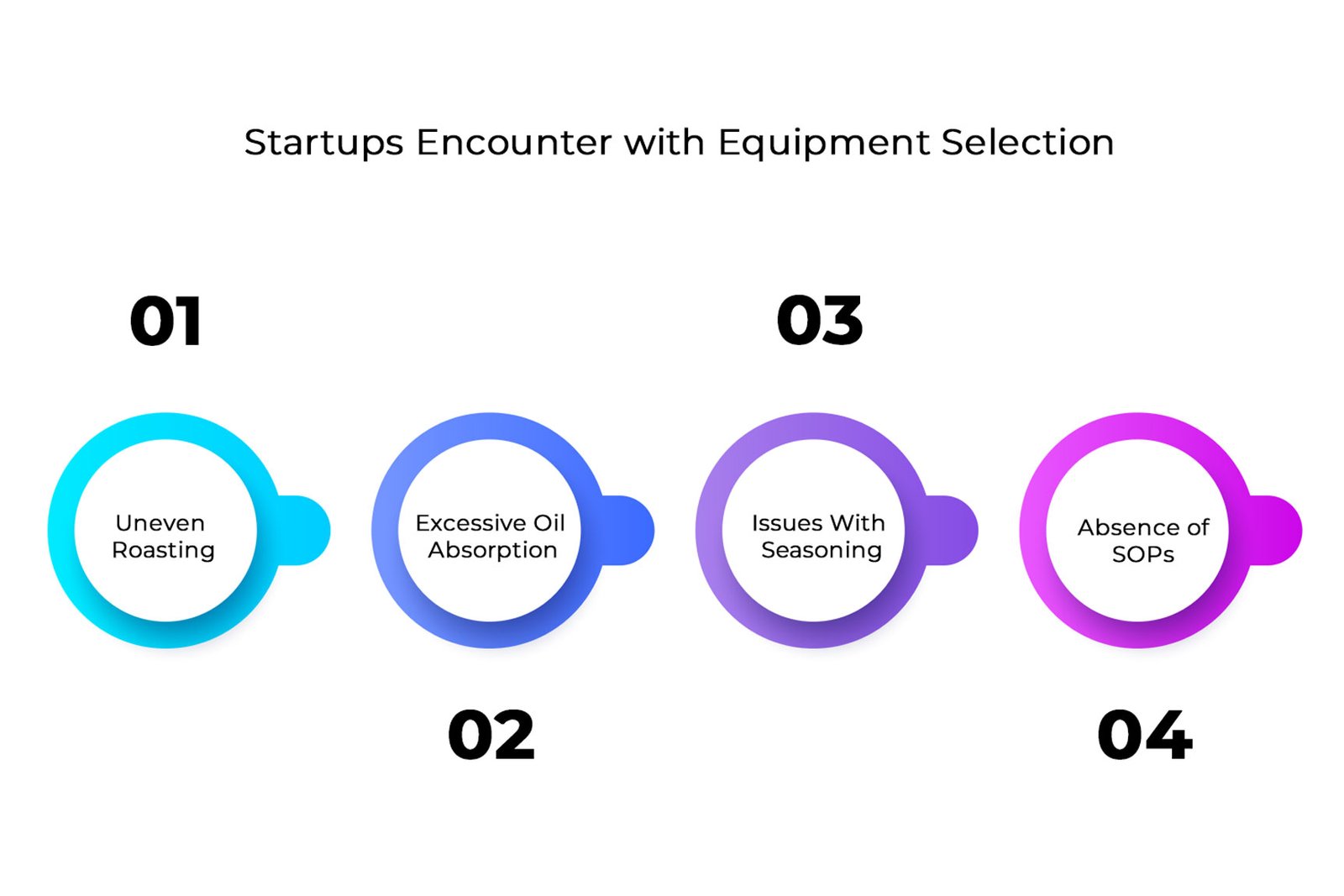

A startup’s journey is usually full of high hopes, but most of the time, the founding teams make critical errors in their equipment choice. Here are the typical problems that startups encounter with equipment selection:

- Uneven Roasting: The centre of the makhana is possibly still raw while the outside is already burnt. This ultimately ends up being a low-quality product that does not satisfy the consumer’s expectations.

- Excessive Oil Absorption: If the machine does not monitor the amount of oil used properly, you not only lose the health positioning of your product, but also it can cause rancidity over time.

- Issues With Seasoning: The seasoning is not coming to the makhana in the right way, and the powder is likely to settle at the bottom of the pack, making the experience of chewing unpleasant.

- Absence of SOPs (Standard Operating Procedures): When there are no standard procedures, there is a variability of the batches. Without clear SOPs, every batch would have variations in the quality, which results in discrepancies in flavour and texture and eventually customer satisfaction.

What You Actually Need in a 50–200 Kg/Hr Startup Line

When ordering your makhana production line, you should understand that roasting is not the only part of production. In order to ensure uniformity in quality and minimise wastage, such an extensive line of coverage that covers all vital facts of production is needed. Selecting one depends on the following factors:

1. Sorting and cleaning:

- Purpose: To remove the contaminating factors like stones, dust and other undesired particles before roasting.

- Solution: Choose a machine with a cleaning capacity of effective air jets or sieves during pre-roasting. The first cleaning process defines the nature of the whole production process.

2. Roasting:

- Purpose: The goal is to make the makhana’s characteristic crunchy texture by drying it out evenly.

- Solution: A rotary or continuous drum roaster with an air blower/exhaust is the best for startups. It ensures uniform heat distribution, preventing raw or burnt makhanas.

3. Coating and Seasoning:

- Purpose: To add flavour while securing the perfect adhesion of seasonings.

- Solution: Implement a strong coater that can rotate in both directions and adjust the RPM to fit your needs for perfect seasoning. A self-operating spraying system guarantees that the seasoning sticks well and no excess powder is used.

4. Cooling:

- Reason: To avoid the soggy characteristic and eliminate excess moisture that is left over after roasting.

- Solution: Forced-air cooling or cooling conveyors are used to stabilise texture and maintain crispness.

5. Packaging:

- Purpose: Shelf life preservation and oxidation prevention were the main goals.

- Solution: Go for a packaging system that has a nitrogen flushing option as part of it. This will enhance shelf life and maintain the crunchiness of the makhana. The modularity in pouch width will aid in different packaging sizes.

Best Machine Options by Capacity (50–200 Kg/Hr)

| Startup Capacity | Best Roaster Type | Why It Works | Ideal For |

|---|---|---|---|

| 50–80 kg/hr | Batch Drum / Rotary Roaster | Provides better control, lower investment, and stable crunch | Early-stage brands |

| 80–150 kg/hr | Continuous Drum Roaster with Blower | Higher output, better uniformity, and energy efficiency | Growing brands |

| 150–200 kg/hr | Industrial Continuous Roaster + Coater Line | Ensures commercial consistency, lower batch variation | Distribution scale |

Specification Table (What to Ask Vendors Before Buying)

| Machine Section | Must-Have Specs | What It Solves |

|---|---|---|

| Roaster | Temperature control, uniform tumbling, insulation, air blower / exhaust | Prevents uneven roasting, burnt taste, and oil loss |

| Makhana Seasoning Machine | Dual-direction rotation, misting / spray option, controlled RPM | Ensures even masala coating and prevents seasoning fallout |

| Cooling | Forced air cooling or cooling conveyor | Prevents moisture buildup and maintains crispiness |

| Oil Dosing | Automated dosing system with a measurable percentage | Controls oil percentage for better flavour and shelf life |

| Packaging | Sealing, nitrogen flushing option, flexible pouch width | Extends shelf life, retains crunch and ensures quality |

Best roasted makhana machine for startups in India

Best Choice: Continuous drum roaster with air blower + integrated seasoning coater + nitrogen packing.

Why: It guarantees consistent output (50–200 kg/hr), homogeneous heat distribution and continuous processing on a scale without quality variation.

- Air Blower: It ensures the even roasting of the bean through the blowing of heated air and the reduction of cold spots, as well as burnt product.

- Added Coating: Dual-level seasoning adhesion improves flavour retention and minimises waste.

- Nitrogen Packing: It retards oxidation and increases shelf life, preserving crispness.

Avoid heavy CAPEX if:

- Flavour/masala formulas are still subject to change.

- Target oil % and moisture profile are not clear.

- Packaging shelf life is not yet validated.

- Sales volumes are difficult to predict.

Case Study (Startup Reality)

1) Indian Krunch – Achieving Roasting and Seasoning Consistency on a Large Scale

-

- Problem: Variation in crunchiness and seasoning loss from one batch to another, which leads to a decrease in consumer satisfaction and a halt in the scale-up process.

- Industrial Fix: The roasting temperature was standardised (±2°C) through automated PID control. The coater RPM and spray bar pressure for the seasoning application were optimised for uniformity.

- Outcome:

- The repeat purchase rate went up by 15%.

- Distributor confidence was increased by 30%, which in turn improved retail placement.

2) HOM Makhana Brand – Shelf Life Improvement & Oxidation Control

-

- Problem: The occurrence of rancidity and sogginess of the product during storage leads to high returns and dissatisfaction among customers.

- Industrial Fix: Oil quality controls were established, and regular batch testing for rancidity markers was carried out. Cooling SOPs were fine-tuned (with cooling of 15-20°C after roast, assured).

- Outcome:

- The shelf life was extended by 40%, from 6-9 months.

- The crunch retention over a period of 6 months improved by 20%.

- Customer satisfaction, as evidenced by fewer returns and a 25% uplift in regular purchases.

Startup Buying Checklist (5 Questions to Ask Before You Pay)

Before you buy a machine, you should ask these important questions:

- Does the machine roast the inner core consistently?

- Is it possible to regulate oil dosage in a quantifiable percentage?

- Does the coater provide uniform adhesion of the masala?

- Is the cooling effective enough to stop moisture buildup?

- Will packaging preserve crunch for the duration of your intended shelf life?

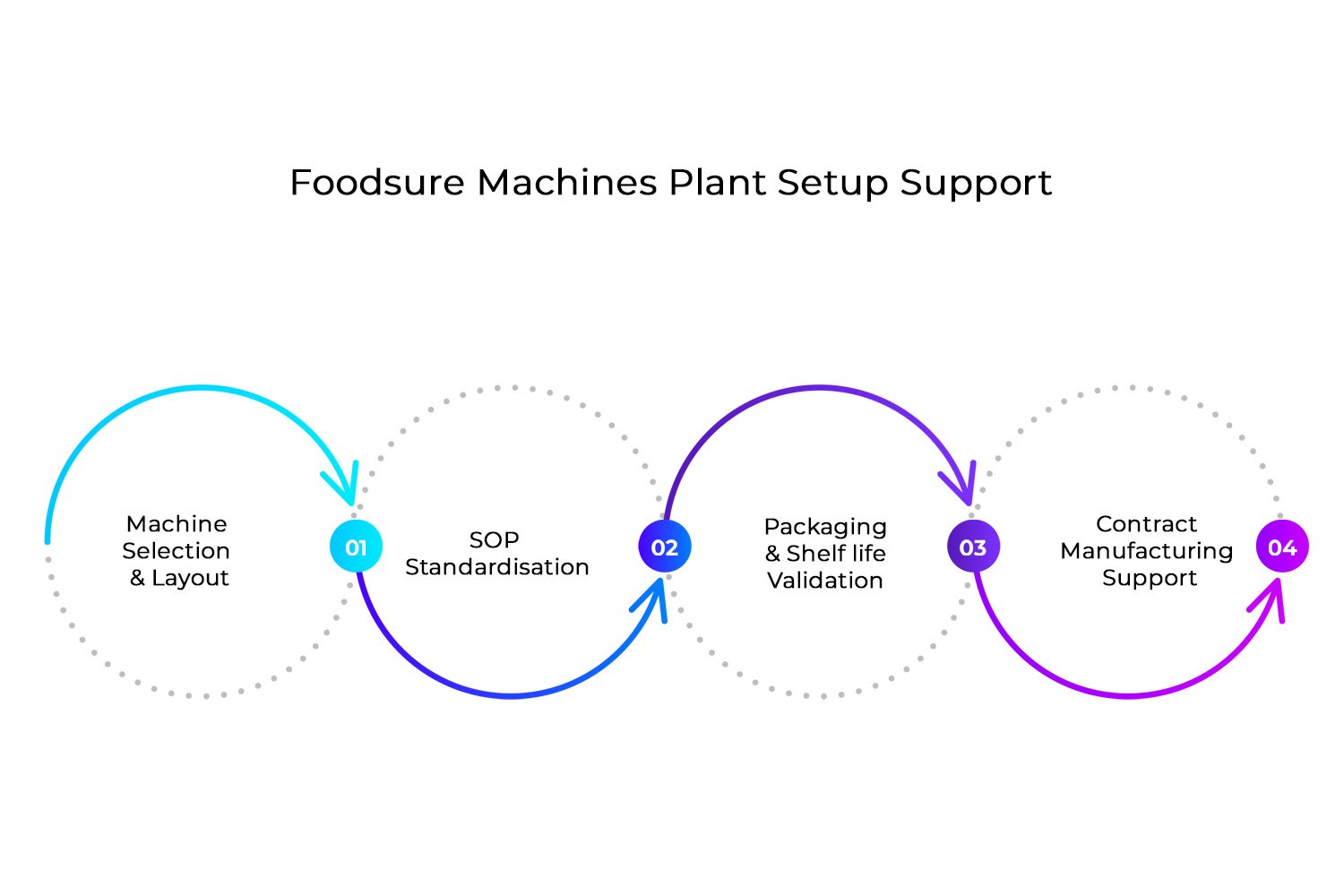

Foodsure Machines Plant Setup Support (What We Standardise)

- Machine Selection & Layout: Selection of makhana processing plant setup with a capacity of 50-200 kg/hr that fit right and are user-friendly, arranged so that cross-contamination and bottlenecks are minimised.

- SOP Standardisation: Processes for roasting, coating, cooling and packaging to be documented and sensor calibrated in order to achieve consistency and low rejects.

- Packaging & Shelf-life Validation: Barrier film selection by empirical method, nitrogen flush validation, accelerated shelf testing and moisture migration analysis.

- Contract Manufacturing Support: A complete production option to test the product/market fit before making investments in capital expenditure.

Conclusion

Our roasted makhana solutions at Foodsure Machines are designed for more than just output; we also aim for consistent crunch, consistent seasoning, and extended shelf life. To help companies scale their brands rather than breakdowns, our 50-200kg/h processes combine regulated roasting, coating, cooling, and packaging.

FAQs

Which is the best roasted makhana machine for a startup in India?

A continuous drum roaster with an integrated roasting and seasoning line of 50–200 kg/hour offers a strong balance of output, consistency, and product quality.

What should be the best capacity of a makhana roasting machine at a low level?

A batch drum roaster or rotary mill with a capacity of 50–80 kg/hour is ideal for beginners to develop recipes and standard operating procedures.

How much does a 100 kg/hour roasted makhana machine cost in India?

Prices vary based on configuration, automation level, and process features, with higher automation and quality demanding higher investment.

Will one machine be sufficient for roasting makhana?

No. A complete processing line including roasting, seasoning, cooling, and packaging is needed to ensure consistency and long shelf life.

What kind of roasting machine makes makhana uniformly crunchy?

An electronic drum roaster with precise temperature control, controlled tumbling, and an air blower ensures uniform crunch and reduces uneven roasting.