Marketing campaigns for makhana items are frequently launched by FPOs and small businesses without first ensuring their production lines are prepared. What was the outcome? Lost customers, erratic quality, and delays. Investing in makhana machines before marketing is a key component of successful businesses. This assures that your marketing promise can be fulfilled, in addition to improving quality and cutting down on waste. These 7 boosters help maximise ROI and get your production line ready for your first campaign.

Booster 1 – Automate Roasting for Consistent Quality

The automatic roasting machine of makhana eliminates the guesswork in production and guarantees perfect consistency for all the batches. The roasters, which are working automatically, have controlled temperature and even distribution of heat all along, thus inhibiting under- or over-roasting.

Reasons:

- Provides the same flavour, crunchy texture and colour every time.

- Minimises the number of rejected batches and buyers’ complaints.

- Increases the life of the product by removing the moisture.

- Makes it possible to increase production without sacrificing quality.

- Reduces reliance on skilled workers.

Larger brands that are planning to scale up will benefit from the automated roasting as it guarantees that all the products that are marketed will have the same quality standard.

Booster 2 – Upgrade Grading for Premium Presentation

Grading distinguishes a local product from a brand ready for the market. The automatic makhana grading machine separates kernels according to their dimensions and quality, so every pack looks the same visually. The manual grading method is slow, inconsistent, and mixing sizes occurs frequently, which bulk buyers can tell right away.

Reasons for grading improvements:

- Creates packs that are not only uniform but premium in appearance.

- Helps obtain better prices and margins.

- Eliminates complaints and returns from buyers.

- Accelerates the process of packing and dispatching.

- Increases modern retail brand perception.

Through consistent grading, your product appearance is aligned with the promise made in your marketing.

Booster 3 – Streamline Packaging to Avoid Delays

In most cases, Packaging turns out to be the largest invisible bottleneck in makhana units. Using semi-automatic and automatic makhana packing machines, the process of filling, sealing, and labelling is made uniform, and the delays due to manual handling are completely removed. When demand in marketing rises, packaging that is fast and reliable becomes important in meeting the dispatch deadlines.

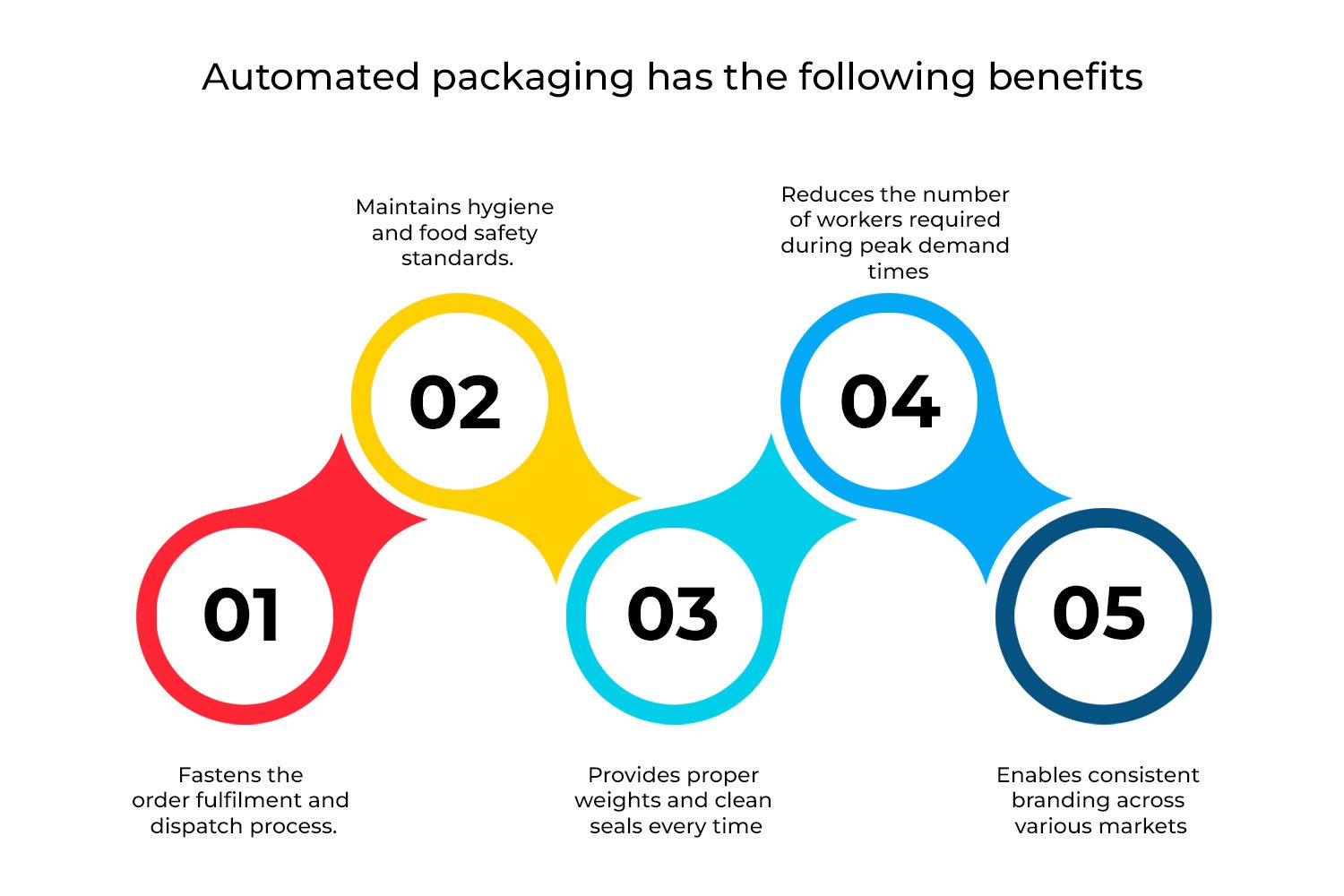

Automated packaging has the following benefits:

- Fastens the order fulfilment and dispatch process.

- Maintains hygiene and food safety standards.

- Provides proper weights and clean seals every time.

- Reduces the number of workers required during peak demand times.

- Enables consistent branding across various markets.

Packaging that is efficient guarantees that your market reach is as fast as the delivery.

Booster 4 – Reduce Wastage & Optimise Costs

Makhana processing carried out manually mostly causes breakage, over-roasting, spillage, and uneven output; all of these factors contribute to the increase of hidden costs. Automatic makhana making machine provides exactness at all the phases, which considerably reduces material loss and the reworking process. The first expenditure could appear to be a lot, but the decrease in wastage and the increase in usable output are the factors that soon equal the cost.

The impact of machines on cost efficiency enhancement:

- Minimise breakage and over-processing losses.

- Increase yield per batch.

- Reduction of repetitive work and rejection rates

- Maximise raw material utilisation.

- Bring about faster ROI through consistent output.

The production that is controlled results in margins that can be predicted and in sustainable growth.

ROI Breakdown: Investing in Makhana Machines Before Marketing

| Machine | Approx. Cost (₹) | Production Capacity | Time Saved / Day | Expected ROI | Key Benefit |

|---|---|---|---|---|---|

| Automatic Makhana Roaster | 3,00,000 – 5,00,000 | 50–100 kg/hr | 6–8 hrs | 12–18 months | Uniform roasting, reduced manual errors |

| Makhana Grading Machine | 1,50,000 – 3,00,000 | 50–100 kg/hr | 4–6 hrs | 10–14 months | Consistent product size, premium packaging |

| Packing Machine (Semi / Automatic) | 2,50,000 – 4,00,000 | 50–120 packets/hr | 5–7 hrs | 12–16 months | Faster packing, hygiene compliance |

| Makhana Cooling Conveyor | 80,000 – 1,50,000 | 50–100 kg/hr | 3–4 hrs | 8–12 months | Preserves quality, reduces spoilage |

| Pre-Cleaning & Sorting Unit | 1,00,000 – 2,00,000 | 50–100 kg/hr | 3–5 hrs | 9–13 months | Reduces wastage, ensures uniform quality |

| Total Investment | 8,80,000 – 15,50,000 | — | — | — | Full production line efficiency & scalability |

Booster 5 – Scale Production for Pan-India Distribution

The distribution across the entire country is expected to be a certain volume with no interruptions in between. Automatic makhana processing machines have made it possible to manufacture continuously, and thereby producers have the confidence to supply the wholesalers, online sellers, and institutional customers.

Once the demand is expanded beyond the local market, manual setups can no longer keep up with the pace.

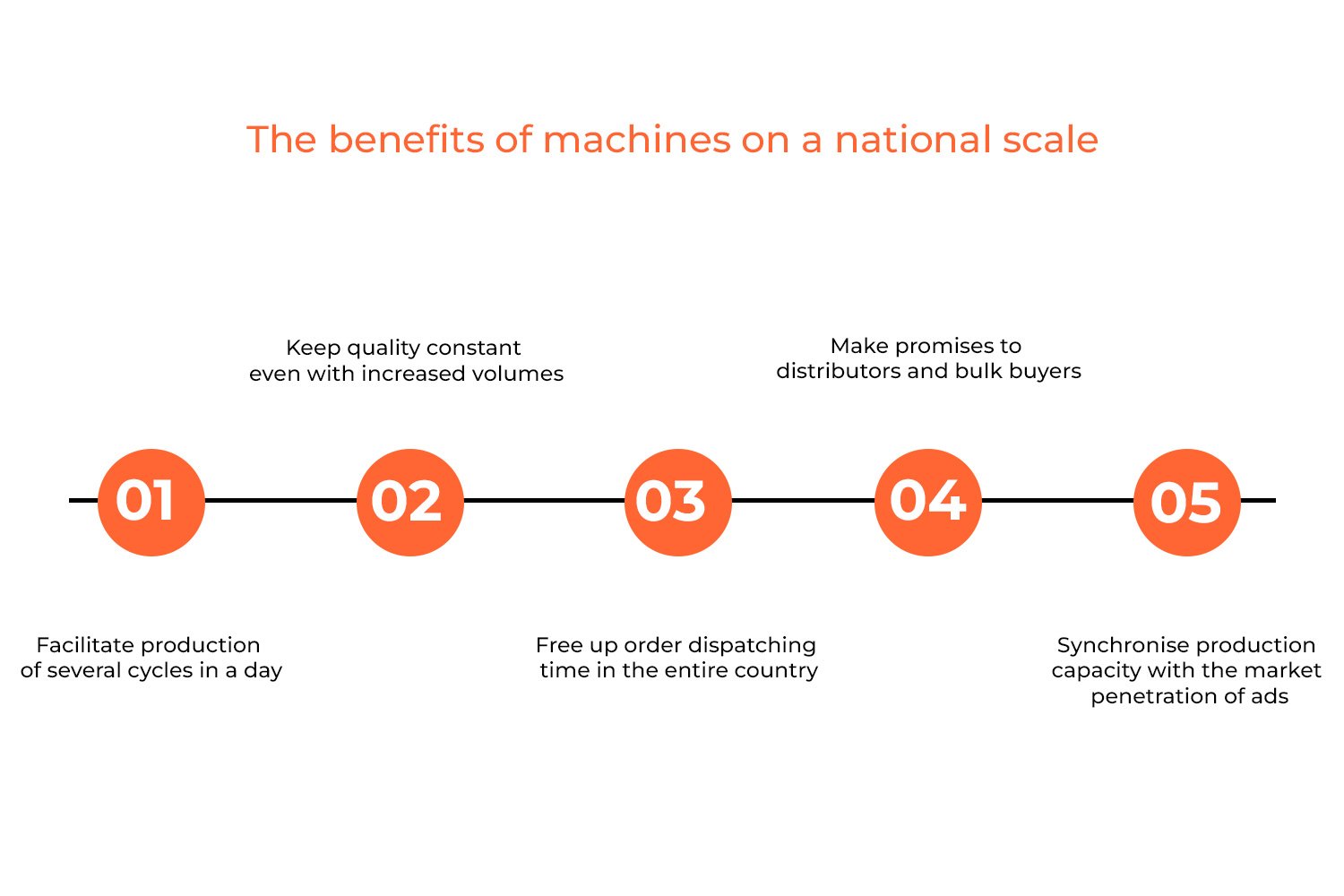

The benefits of machines on a national scale are:

- Facilitate production of several cycles in a day.

- Keep quality constant even with increased volumes.

- Free up order dispatching time in the entire country.

- Make promises to distributors and bulk buyers.

- Synchronise production capacity with the market penetration of ads

Machinery with the capacity to scale will not let the opportunity for growth turn into a failure in delivery.

Booster 6 – Train Staff Efficiently for Smooth Operations

Manual processing relies a lot on the operator’s skill level and, consequently, is slow and prone to errors during training. With standardised makhana machines, fixed settings, and repeatable workflows, operations get simplified. This means that the output quality will be consistent while the new staff are getting up to speed.

The use of machines leads to the improvement of workforce efficiency in the following ways:

- Less training time and shorter learning curves.

- A reduction of human errors in the production process.

- The guarantee of uniform output during shifts.

- A decrease in the reliance on highly-skilled workers.

- The avoidance of production slowdowns during the change of staff.

Stable production is ensured by well-trained operators and the use of automation even during rapid scale-up.

Booster 7 – Align Marketing Spend with Production Capacity

Marketing campaigns have no chance of success if their production cannot keep up with the demand. Overpromising causes delays, unhappy customers, and consequences for the brand. First, investing in automated makhana machines will allow you to accurately track daily output, plan order fulfilment accordingly, and scale marketing campaigns with confidence, without risking running out of stock.

Here are the reasons why it is so important to ensure the marketing department is in sync with the production department:

- It ensures that orders are filled in accordance with actual production capacity.

- It avoids the situation where sales are lost because demand was not met.

- Buyer trust and brand credibility are built to a high degree.

- Marketing funds are used in a very efficient way, leading to the best ROI possible.

- The growth of the company is made sustainable and scalable across various areas.

Production-ready marketing will not only protect the company’s reputation but also ensure that the returns are maximised.

Conclusion

Investing in makhana machines before marketing ensures consistent quality, scalable production, and faster ROI. With the right setup from Foodsure Machines, brands can align capacity with demand, reduce risk, and grow confidently across markets.

FAQ

Why is investing in makhana machines before marketing important?

Marketing only works when production can keep up. Without machines, demand leads to delays and complaints. With machines, capacity, quality, and delivery stay predictable before orders begin.

Which machines should be prioritised before marketing makhana products?

Roasting, grading, and packing matter most. They define taste, appearance, and delivery speed—solving most operational issues upfront.

How does investing in makhana machines before marketing improve ROI?

It creates cleaner production with less breakage, minimal rework, and fewer rejected batches. Marketing brings orders, but smooth production delivers profit.

Can small manufacturers afford investing in makhana machines before marketing?

Yes, when done strategically. Many start with one or two machines, generate revenue, then expand. Payback is often faster than expected.

How does investing in makhana machines before marketing support pan-India distribution?

It enables confident commitments—multiple daily batches, consistent quality, and reliable dispatch make nationwide supply practical, not risky.