In a place where raw makhana is abundant but processing infrastructure is lacking, the Bihar Startup Case Study turned disorganised production of low value into a high-quality processing model that is structured, unlocked scale, consistency, and ₹2.5 Cr+ annual turnover by means of smart machinery choices.

Founders & Origin Story

- Origin: Patna, Bihar.

- Start Year: November 2024.

- Initial Capital: ₹3 lakh bootstrap funds.

- Initial Team: Two founders + seasonal labour.

Core Idea: Industrialise the makhana value chain, starting with processing and quality control to replace traditional household methods and capture value addition locally rather than export raw nuts for others to process.

Step 1: Building the First Working Machine

Due to the lack of finances for fully equipped processing lines, the creators made a prototype processing machine by themselves using their knowledge of engineering and robotics.

Key points:

- Iterative development for months.

- Found practical solutions: oil odour, humidity control, and uneven expansion quality.

- Sometimes they broke their machines during the trials, but they still continued refining the process.

- Worked 13 hours a day to make the process reliable.

- The first large orders were processed using this prototype machine; it served as a proof of concept before investing in industrial makhana machines.

Step 2: Scaling with Equipment (Real Machines, Real Impact)

- Reinvestment-driven scale-up: When the cash flow turned out to be predictable, the profits, along with the small funding rounds, were directly used for purchasing reliable makhana processing equipment rather than marketing-heavy spending. This made unit economics better and less risky from the very beginning.

- Machine mix adopted: Usually, the scaling units in Bihar are graded for size uniformity, equipped with food-grade continuous roasters of 50 kg/hour+ capacity, then moved to flavouring drums for controlled coating, and finally to pouch packaging units for shelf-ready output.

- Operational impact: The high-capacity makhana machine is capable of getting rid of the batch-to-batch variation, cutting down the dependence on manual labour, and raising the throughput from 20 kg/hour or even more through hours of handwork.

- Market expansion: The standard roasting and flavouring lead to the availability of the same SKUs, classic, spicy, cheese, health blends, while the good packaging opens the door for the retail, distributors, and B2B buyers.

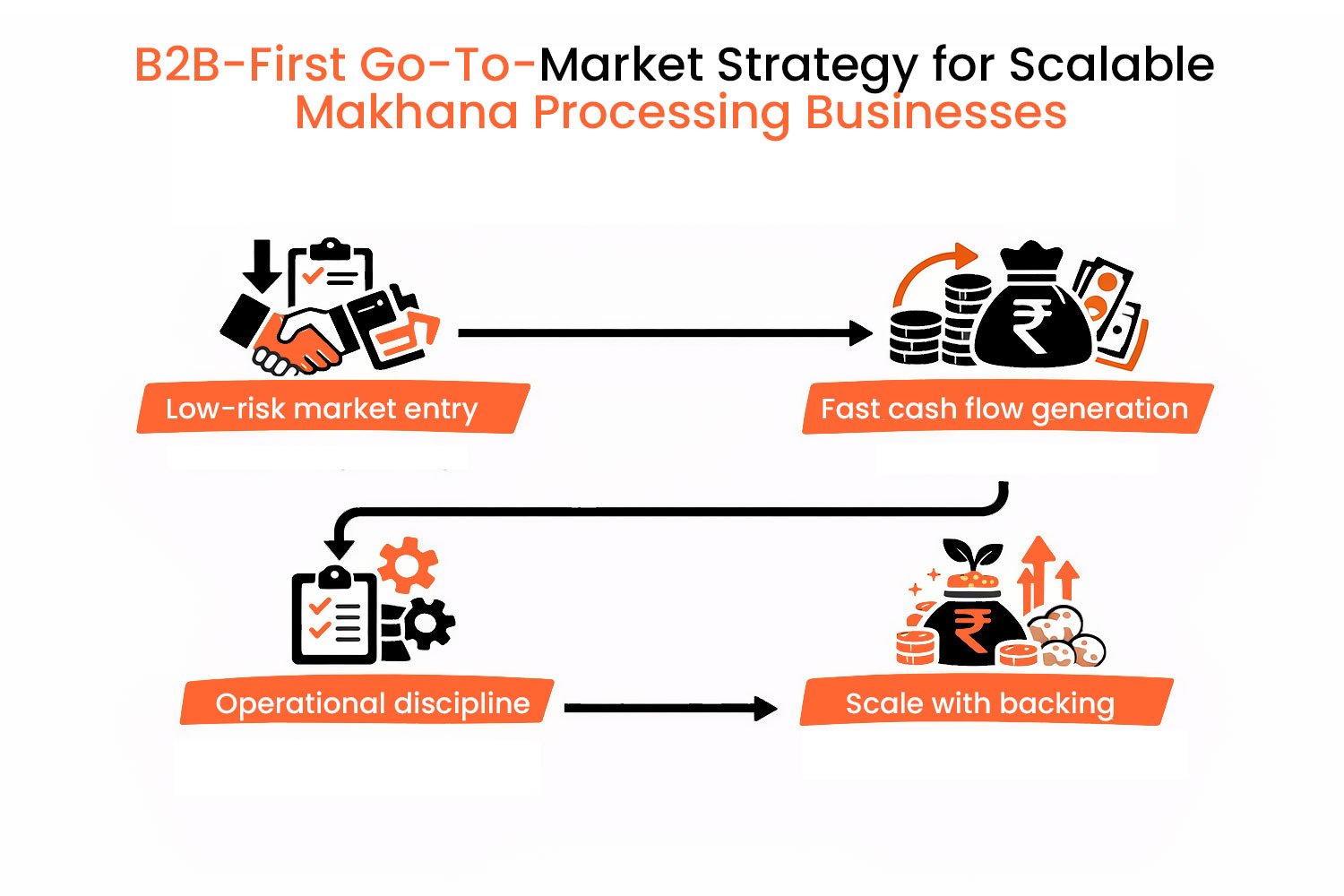

B2B-First Go-To-Market Strategy for Scalable Makhana Processing Businesses

- Low-risk market entry: Rather than using their whole budget for developing a brand, the founders opted for a B2B white-label route, selling processed makhana to already existing brands that had distribution and demand.

- Fast cash flow generation: B2B bulk selling took place without any advertising costs, no retail listing fees, and little packaging complexity, which helped the unit to concentrate entirely on production efficiency.

- Operational discipline: The production of the very first order worth ₹ 4 lakh compelled the company to implement very strict quality control, ensure batch consistency, and meet delivery timelines, which are the very skills needed to scale.

- Scale with backing: Firm orders and bills strengthened their application for PMFME-type government schemes, which led to obtaining expansion capital.

Key Outcomes: How a Makhana Processing Unit Scaled from Prototype to ₹2.5 Cr+

| Metric | Result |

| Annual Turnover (2025 estimate) | ₹2.5 Crore+ |

| Facility Size | 10,000 sq ft production unit |

| Farmer Network | 2,500+ associated farmers |

| Brand Partnerships | 40+ national & international |

| Manufacturing Workforce | 18 full-time + seasonal labour |

How the Right Strategy and Makhana Processing Machines Enabled Scale

- The right machinery as the backbone: The introduction of food-grade makhana processing machines not only brought about repeatable roasting profiles, but also uniform grading and predictable output, all of which are essential in meeting B2B quality clauses.

- Production capacity increased to more than 50 kg per hour, flavour coating was done with precision, and the margins per kg were better compared to the sale of raw produce.

- A value chain that is systematically organised: The direct connection with farmers lessened the quality difference and prevented the supply shocks that would otherwise come.

- The fewer the middlemen, the better price control and the having the opportunity to schedule production according to the institutional specifications rather than the spot-market availability.

- An overall sales strategy that was well-balanced: B2B orders were the first to give a stable cash flow. Only after they had proved their volumes, quality, and delivery discipline did they invest in building a consumer brand of their own.

Also read: Start Makhana Business In Bihar: 7 Powerful Steps To Succeed

Real Challenges Faced by a Growing Makhana Processing Unit

- Capital pressure: Makhana making machine failure without a sufficient buffer hit cash flow hard every time, since funds were limited. Idle inventory and long experimentation were not tolerated.

- Engineering risk: Inconsistent batches and material loss were the results of several breakdowns during trials, making learning costly before processes were stabilized.

- Market trust gap: Proof of consistency, audits, and repeat samples were the only ways for buyers to risk committing volumes to an unknown processor.

- Compliance complexity: A young unit could not afford the time and the costs that came with strict labeling, shelf-life validation, and certifications, which were demanded by export and large buyers.

- Operational strain: Seasonal labour, variation from batch to batch, and fluctuating raw makhana prices were giving constant pressure on both margins and planning; thus, they had to be managed carefully.

Conclusion

The Bihar Startup Case Study illustrates the way Foodsure Machines‘ precision machines guarantee uniformity in quality, increased output, and dependable and quantifiable growth. We facilitate the shift of unprocessed makhana into lucrative, market-ready products by providing support for new companies’ efficient scaling.

FAQ

What is this Bihar Startup Case Study about?

It shows how a makhana startup in Bihar scaled production by fixing what was breaking inside its processing setup.

Which industry does this Bihar Startup Case Study focus on?

It focuses on makhana processing and value-added food manufacturing.

Why is Bihar important for makhana startups?

Because most of India’s makhana comes from Bihar, access to raw material is already solved.

What was the biggest challenge faced by the startup?

Rising demand exposed weak capacity and inconsistent processing.

How did machine limitations affect growth?

Low-capacity machines slowed output, hurt consistency, and caused missed orders.

What role did automation play in this case study?

Automation reduced human error and kept production stable during peak demand.

Did the startup move from raw sales to value-added products?

Yes. Processing turned raw makhana into higher-margin, market-ready products.

How did quality consistency impact market acceptance?

Once quality stabilized, buyers trusted the product and orders repeated.

Is this Bihar Startup Case Study relevant for FPOs and SHGs?

Absolutely, because the same scale and processing challenges show up there, too.

What was the impact on daily production output?

Removing bottlenecks led to steady, predictable output gains.

Does this case study show scalable business potential?

Yes. Scale depends on machines, not demand.

What is the key takeaway from this Bihar Startup Case Study?

Demand creates opportunity. Weak processing systems decide who can handle it.