Hand-packing makhana works when you are small. But as orders increase, it holds you back. It’s slow, inconsistent, and too dependent on labor that may not show up. You end up with uneven pouches, and real questions about hygiene. Smart packaging changes that. These makhana packaging machine with nitrogen flushing can seal 200 to 3,000+ pouches an hour. Makhana machines don’t guess weights. Each unit operates with precision, speed, and consistency.

This is exactly where a packaging machine for makhana changes the game. Instead of depending on manual work, a smart packaging machine gives you consistent sealing, accurate filling, and the ability to scale without stress.Many growing units now prefer a makhana pouch packing machine because it handles delicate kernels gently while maintaining speed and hygiene.

3 Ways Hand-Packing Is Slowing Your Growth

When comparing the difference between manual and automatic packaging machines, the gap becomes clear in speed, hygiene, and long-term reliability. The flexible packaging machinery market is projected to grow from USD 8.6 billion in 2025 to USD 13.7 billion by 2035, with a CAGR of 4.8%. The market shows steady growth, beginning at USD 6.8 billion in 2021 and reaching USD 8.6 billion by 2025.

-

Slow output means missed orders

A packing machine small size unit can already outperform manual labor several times over, making it ideal for small processors ready to scale. If you are hand-packing, you are probably managing a few hundred pouches an hour at best. That might work for now, but as orders grow, delays start stacking up. Deadlines slip. Buyers lose patience. And you lose business.

-

Inconsistent weights lead to complaints

Humans aren’t machines. Pouch weights vary. Some are underfilled, others over. That’s not just a quality issue, it’s a trust issue. And in some cases, it’s a legal one too.

-

Labor becomes a bottleneck

This is why many processors shift first to a semi automatic makhana packaging machine before upgrading to a full smart packaging line.The kind who show up on time, work consistently, and don’t leave after two weeks. That’s hard to find and harder to manage. You spend more time training and chasing reliability than running the business.

From Local to Global: Trends That Make Automation a Must

If we’re being honest, manual packing won’t take you far. A food-grade makhana packaging machine makes a real difference when you are ready to grow beyond local limits.

-

Exports need better packaging

Strong makhana export packaging isn’t just about looks — it’s about airtight sealing, nitrogen flushing, and consistent weights that meet international standards. A reliable makhana pouch packing machine ensures every export pack meets hygiene and shelf-life expectations.

-

Retail needs shelf-ready, barcoded packs

Modern retailers now expect packaging automation solutions that deliver barcode-ready, uniform pouches at scale.

-

Buyers expect reliability

Distributors want airtight seals, correct weights, and traceability. Automation gives them that and gives you fewer headaches.

READ MORE: Makhana Machine Trends 2025: Industry Growth & New Opportunities

Built for Growth: Inside the Machinery of a High-Performance Makhana Line

If you are building a serious operation, the food-grade makhana machine isn’t just a tool; it’s the engine that drives speed, consistency, and scale. Let’s look at what goes into a high-performing line.

-

Core Components:

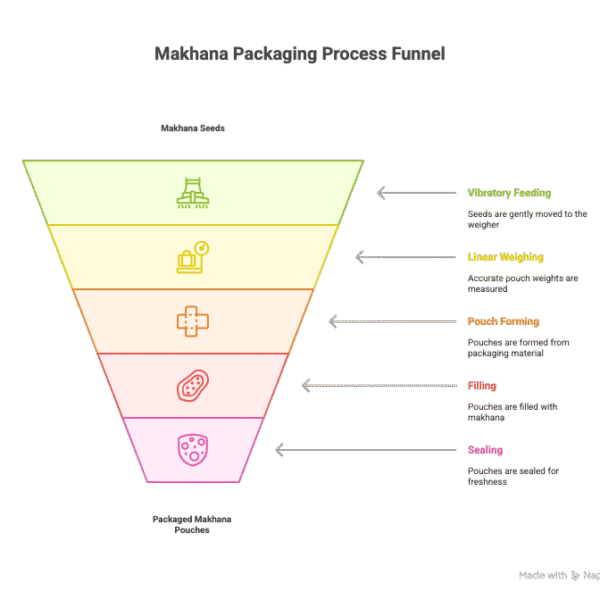

A smart makhana pouch filling and sealing machine isn’t just faster, it’s developed to solve real problems. It starts with a vibratory feeder that moves the seeds gently to a linear weigher. That gives you accurate pouch weights without crushing the product. From there, the FFS machine forms, fills, and seals each pouch up to 60 per minute with clean, consistent results. This entire setup works as a smart packaging line, where feeding, weighing, filling, and sealing operate in one smooth, automated flow. For growing businesses, this type of packaging automation solutions setup reduces errors while improving output consistency.

-

Output You Can Expect:

- High-speed output: Even a packing machine small size model can handle serious volumes compared to hand packing, making automation accessible for smaller units. A well-built small scale packaging machine can push out 30 to 60 pouches a minute. That kind of speed isn’t just impressive, but it also helps you to hit big orders on time and opens the door to serious retail and export volume.

- Flexible pouch sizes: That flexibility is one reason automatic makhana packing machine reviews often highlight adaptability as a key benefit. Even if you are selling trial packs or bulk family bags, the system handles weights from 10g to 200g without hassle. You can adjust quickly, match customer demand, and stay versatile as your product range grows.

- Cost efficiency: Makhana packaging machine price run anywhere from ₹1.5 to ₹6 per pouch. It depends on your setup, level of automation, and pouch size, but the key is this: you control the cost, and you get the speed and quality to justify it.

From Manual to Profitable: How Smart Packaging Changes the Game

Many processors researching automatic makhana packing machine reviews mention the same benefits: lower labor stress, better pack quality, and faster dispatch times. Whether you start with a semi automatic makhana packaging machine or go fully automatic, the move toward a smart packaging machine pays off quickly.

If you are running a small-scale makhana packing unit, smart makhana pouch filling and sealing machine cuts your labor needs fast. It automatesmakhana pouch filling and sealing machine, so you rely less on manual work and avoid the slip-ups that come with it. That alone speeds up production and helps you ship faster.

Read More: From Manual To Modern: How Advanced Makhana Processing Machines Transform The Industry?

Real Results: A Bihar Unit’s Jump from Manual Labor to Smart Output

The unit first considered a small scale makhana packaging machine, but demand pushed them toward a complete smart packaging line instead.

-

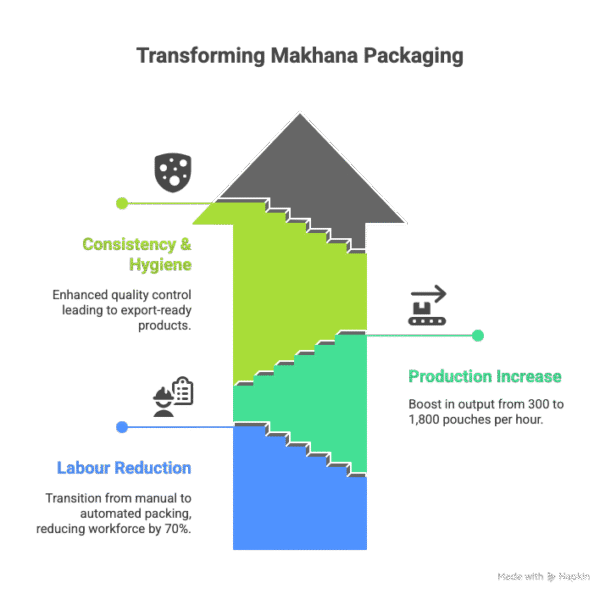

Labour reduction

A makhana unit in Bihar went from depending on three workers on the packing line to just one operator. That one shift cut labor costs by nearly 70% without slowing production.

-

Production capacity increase

Before the switch, how many bags can the small scale makhana packaging machine make per minute, the team was managing about 300 pouches an hour by hand. After switching to an automatic makhana machine, the output jumpedto 1,800 per hour. Their upgrade to a makhana pouch packing machine also improved sealing quality, making the packs suitable for makhana export packaging.That’s six times the output with a smaller team.

-

Improved consistency and hygiene

Automation took the trial and error out of filling and sealing. Pouches looked cleaner, weighed right, and sealed tight, exactly what buyers want. The unit could now serve export orders and retail shelves with confidence.

Read More: Village to Growth Hub: How Makhana Machines Are Building Rural Prosperity in Bihar

Scaling Options Comparison: Which Packaging Setup Fits Your Unit Best?

If you’re still unsure about the difference between manual and automatic packaging machines, this comparison makes the growth path easier to understand.

| Feature | Hand-Packing | Semi-Automatic Packaging | Fully Automatic Line |

|---|---|---|---|

| Speed (pouches/min) | 5–10 | 20–30 | 30–60+ |

| Accuracy | Low | Medium | High |

| Labor Requirement | 3–5 people | 2 people | 1 operator |

| Cost per Pouch | High (manual) | Moderate | Lowest |

| Barcode/Batch Coding | Manual | Optional | Integrated |

Read More: Air-Tight, Shelf-Stable: How a Makhana Airtight Packaging Machine Boosts Shelf Life by 40%

From Manual to Market-Ready—Let’s Design Your Smart Packaging Line

Foodsure Machines provides complete packaging automation solutions designed specifically as a packaging machine for makhana, whether you need a starter packing machine small size model or a high-speed smart packaging line. What you get is speed, consistency, and clean, retail-ready packs that meet market standards. Foodsure Machines, automatic makhana machine are easy to run. Training is hands-on. Support is ongoing. So, you can move from hand-packing to efficient, export-ready production without stress. It’s a smarter way to grow, even if you are processing 500 kg a day or gearing up for more.

Ready To Upgrade Your Makhana Packing?

Reach out to us anytime via call or email.

FAQ

What is a makhana pouch packing machine?

It’s an automated system that fills and seals makhana in uniform pouches for retail or export.

How does a packaging machine for makhana help small units?

It speeds up production, ensures consistent weight, and reduces labor needs.

What is the difference between manual and automatic packaging machines?

Manual is slow and inconsistent; automatic machines deliver precise, hygienic, and high-speed packing.

Can makhana export packaging meet international standards?

Yes, automated machines with nitrogen flushing and airtight sealing make pouches export-ready.

What is a smart packaging machine?

A smart machine automates weighing, filling, and sealing, ensuring uniform packs every time. Ask about our smart lines.

How does a smart packaging line improve efficiency?

It integrates all processes—feeding, weighing, filling, sealing—cutting errors and boosting output.

What are packaging automation solutions for makhana?

They range from semi-automatic to fully automatic lines that reduce labor and improve pack quality.

Are there automatic makhana packing machine reviews?

Yes, users report faster production, accurate weights, and better hygiene.

What is a semi automatic makhana packaging machine?

It helps small to mid-sized units increase speed and accuracy without full automation.

Can a packing machine small size handle growing orders?

Absolutely, compact machines scale output from a few hundred to thousands of pouches per hour. Get your machine recommendation today.