Makhana demand is increasing, driven by packaged snack brands, export orders, and festive spikes, which are boosting volumes. Yet many processors struggle just when orders increase. This is why makhana businesses fail during high demand. The problem isn’t demand, it’s machine limitations. When capacity, consistency, or uptime breaks down, even a strong market pull cannot be converted into sustainable growth for makhana businesses.

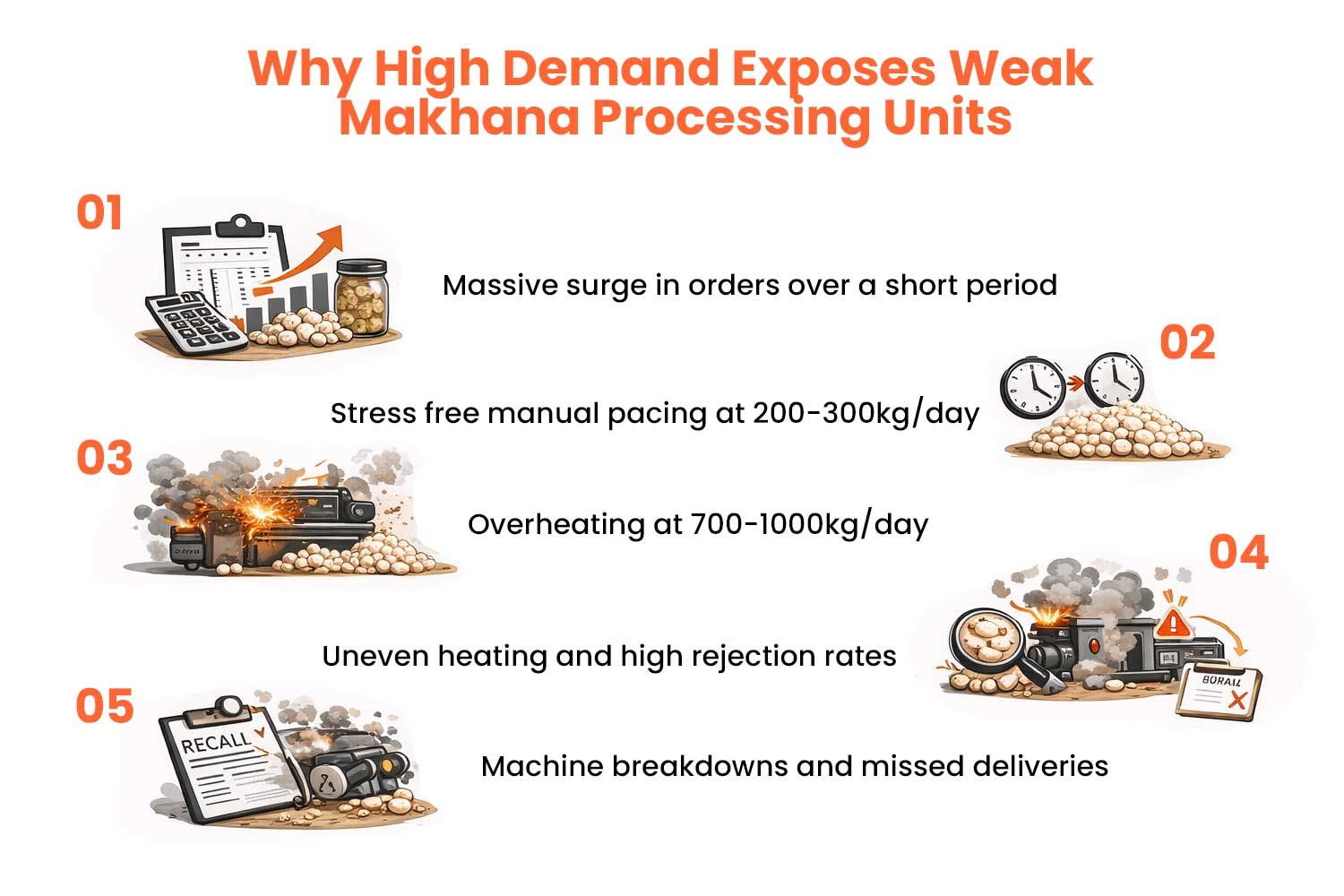

Why High Demand Exposes Weak Makhana Processing Units

Understanding why makhana businesses fail during high demand starts with looking at order spikes and the limits of existing machines.

- During the festive and export seasons, makhana orders are typically placed in extremely high quantities, sometimes even 2–3 times more, over a short period of 10–20 days without any gradual increase.

- According to one report, units operating without issues at a daily capacity of 200–300 kg rely on manual pacing, flexible timing, and low stress on the machines.

- The same machines, when running at a rate of 700–1,000 kg/day, overheat, the temperature goes out of control, and the batch gets mixed up.

- One of the problems faced by roasters is uneven heating; graders also encounter volume and moisture variations, which increase rejection rates.

- The industrial makhana machine was designed for a constant daily output, not for sudden demand surges. It leads to machine breakdowns, quality degradation, and unfulfilled delivery commitments when the profit margins are at their highest.

The Hidden Bottleneck: Machine Limitations Inside Makhana Units

- What this really shows is why makhana businesses fail during high demand: machines that seem adequate at low volumes quickly become bottlenecks under pressure.

- Along with the long roasting process, there is a decline in the accuracy of temperature sensors, a decrease in heat recovery, and, therefore, a problem in maintaining uniformity.

- In addition to the standard incoming moisture typical for bulk seasonal lots, roasting time is increased, and basic heating systems are overloaded.

- Manual feeding and discharge areas start to form queues, which affect the size of batches and lead to hasty processing decisions.

- Gradually, makhana processing machines that were meant for occasional use become the reasons for the slowest production rate, quality loss, and breakdowns due to demand pressure, resulting in inconsistent output. As a result, within the unit, equipment, not labor or market access, becomes the weakest link.

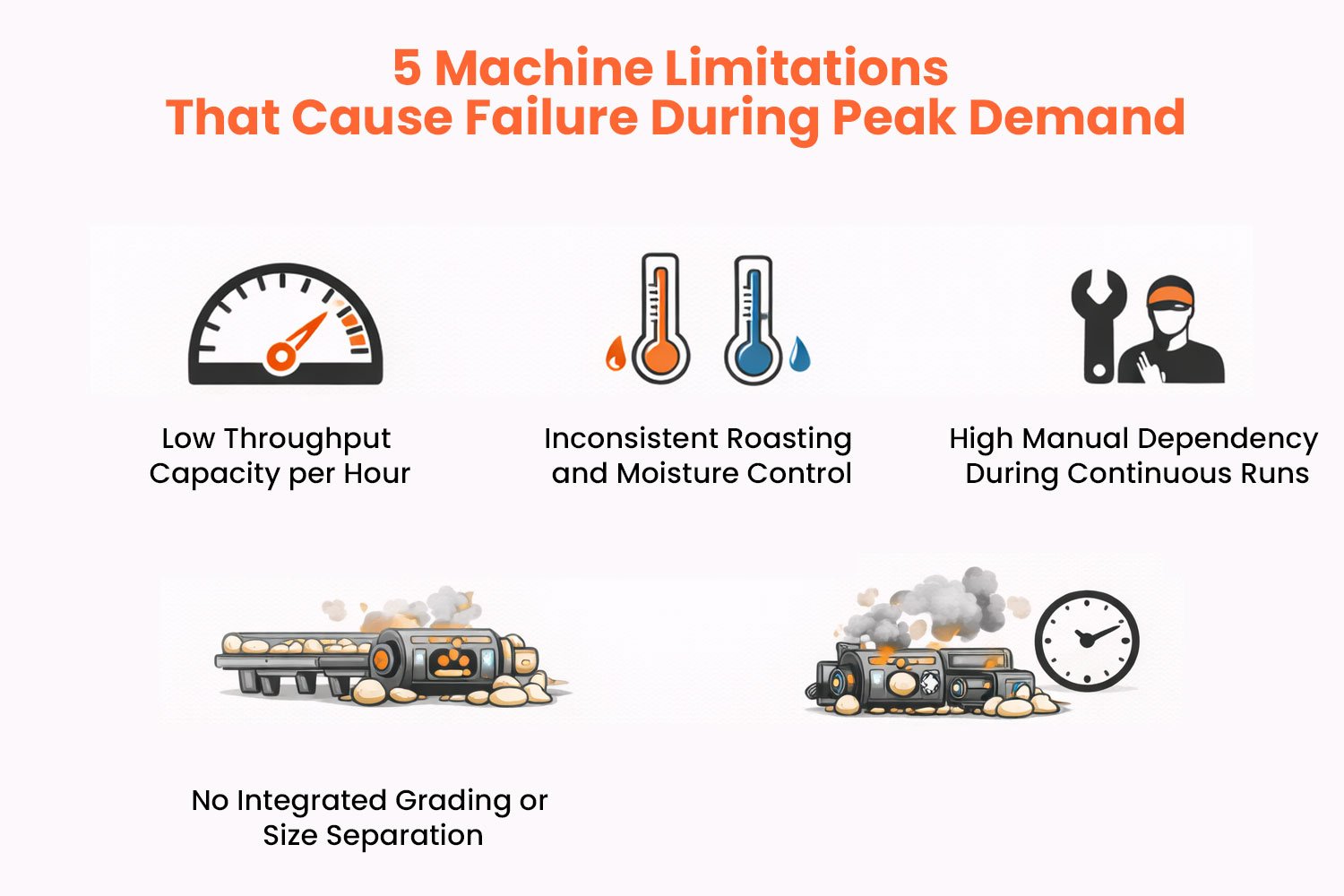

5 Machine Limitations That Cause Failure During Peak Demand

Here’s a breakdown of the key reasons behind why makhana businesses fail during high demand.

- Low Throughput Capacity per Hour

- Many companies install makhana making machines designed to handle trial or pilot output rather than actual market demand.

- A makhana processing machine that can process 20-25 kg/hour simply cannot take the orders that suddenly require 80-100 kg/hour.

- The result is that backlogs continue to grow, dispatch timelines become increasingly longer, and buyers switch to other suppliers even if it is not the season for it.

- Inconsistent Roasting and Moisture Control

- The variations in temperature lead to burnt kernels being mixed with under-roasted batches.

- The inability to control moisture has various negative effects, including loss of crunch, shorter shelf life, and complaints from retailers.

- An automatic makhana roasting machine controls heat and moisture, but only if it is properly designed for load and not labels.

- High Manual Dependency During Continuous Runs

- Manual tasks, such as feeding, unloading, and temperature adjustment, are tiring and can increase fatigue when performed during long shifts.

- The number of mistakes increases after 6-7 hours, and the quality declines at the very time when more is being demanded.

- No Integrated Grading or Size Separation

- The mixture of different sizes in the output makes it impossible to set premium prices, forcing the seller to settle for the average price.

- Governments controlling the buying of bulk want uniformity; without grading, the buyer loses the power to set the price.

- Machines Not Designed for 8–12 Hour Operation

- Overheating, breakdowns, and forced shutdowns occur frequently in the middle of the season.

- When machines are used beyond their comfort limit, design is more important than price.

What Really Breaks Down Inside Makhana Units During Peak Demand

- Week 1: Orders spike

There is a sudden increase in bulk inquiries from distributors and exporters. Production schedules are extended, shifts are increased, and machines are pushed a little harder to keep up with the order.

- Week 2: Delays start

There are throughput gaps. The roasting cycles are slower because the machine overheats, and the moisture has changed. Backlogs are formed, dispatch timelines get longer, and there is a need for temporary fixes that are less than stable instead of process control, which is stable.

- Week 3: Quality complaints

Uneven roasting leads to a mixture of crunch and color. Retaining moisture shortens shelf life, thus causing rejections by buyers and returns by retailers.

- Week 4: Missed deliveries and cash stress

Cancelled orders, penalties, and blocked payments are all together causing a strain in working capital just at the time when the costs for raw materials and labor are at their peak.

Why the Right Makhana Processing Machine Helps Some Units Scale, and Others Fail

- Scalable units choose machines according to the peak season load rather than the daily averages that are comfortable. A makhana production line meant for 900–1,000 kg/day operates at 600 kg continuously without strain, thus providing an extra layer in case of order surges.

- They make the entire process automatic, where the quality is viewed as dependent on the consistency, mainly roasting temperature, time of residency, and moisture control, hence the reduction of pressure-induced variation from one batch to another.

- The machinery is built for uninterrupted 8–12-hour usage, with efficient heat dissipation, constant speed drives, and controlled material flow instead of the traditional stop-start processing.

- These selections prevent overheating, operator fatigue, and quality drift, allowing output to be increased without breakdowns, missed dispatches, or working-capital shocks during high-demand periods.

Also read: ROI Makhana Processing Machine For Village Units

Conclusion

By understanding why makhana businesses fail during high demand, our mission at Foodsure Machines is very clear: design processing plants that ensure uniformity in quality, produce more, and contribute to actual growth. We assist in transforming the unprocessed makhana into ready-to-sell products that are trustworthy for the businesses.

FAQ

What is this case about?

It shows why makhana businesses fail during high demand and how the right machines or the wrong ones can make or break a business.

Which industry does this focus on?

Makhana processing and turning it into high-value, market-ready snacks.

Why does high demand create problems?

Machines designed for average loads can’t keep up when orders suddenly spike.

How do machine limitations affect growth?

Slow or inconsistent machines create delays, missed orders, and frustrated buyers.

Does automation help?

Yes. Automation keeps output steady and reduces human error under pressure.

Can raw makhana be turned into profitable products?

Absolutely. Proper processing transforms raw makhana into snacks that sell for higher margins.

Why is quality consistency important?

Consistent roasting and grading builds trust with buyers and keeps repeat orders coming.

Is this relevant for small manufacturers or FPOs?

Definitely. Small units face the same capacity and machine challenges.

What happens during peak festive or export seasons?

Orders spike, machines overheat, and production can fall apart if the setup isn’t prepared.

Do manual operations solve the problem?

Not really. Long shifts lead to fatigue, mistakes, and uneven batches.

Can proper machines prevent failures?

Yes. Machines built for peak loads keep production running smoothly and quality consistent.

What is the key takeaway?

Most failures aren’t about demand — they’re about systems that can’t handle the load.