Most tomato ketchup plants lose 30–40% energy due to excessive boiling, rising fuel costs, and repeated batch corrections. This increases production costs, affects batch consistency, and puts pressure on margins. A vacuumised tomato ketchup plant solves this by cooking at lower temperatures, preserving natural colour and flavour, and cutting energy consumption by up to 50% without slowing output.

In this blog, we explain how vacuumised ketchup plants benefits, how they reduce energy and fuel costs, the complete process flow, available plant configurations, investment range, and ROI benchmarks to help you decide if this technology is right for your production scale.

Vacuumised Tomato Ketchup Plant – Quick ROI Snapshot

- Energy savings: Up to 30–50% per batch compared to conventional boiling.

- Cooking temperature: 55–70°C (lower heat loss, better colour retention).

- Batch cycle time: 20–35% faster, enabling more daily batches.

- Labour requirement: 25–40% lower due to automation.

- Product consistency: Uniform viscosity, colour, and flavour.

- Typical investment range: ₹8 lakh – ₹75 lakh (based on capacity & automation).

- Estimated payback period: 18–30 months.

Best suited for tomato ketchup plant manufacturer facing high fuel costs, batch rejections, or inconsistent ketchup quality.

Vacuumised Ketchup Plant Configurations (Choose by Scale & ROI)

Vacuum cooking ketchup machineare available in different configurations based on production volume, automation level, and investment capacity. Choosing the right setup ensures faster ROI and stable operations.

Small-Scale Vacuumised Ketchup Plant (Semi-Automatic)

Best for: Startups, FPOs, SHGs, and regional brands.

- Production capacity: 300–800 kg/day.

- Semi-automatic operation with controlled vacuum cooking.

- Lower initial investment and flexible batch sizes.

- Reduced energy consumption with consistent quality.

- Ideal for businesses upgrading from open-pan boiling.

📌 Balances cost control with improved colour, flavour, and yield.

Medium-Scale Vacuumised Ketchup Plant (Automatic)

Best for: Growing brands, B2B suppliers, contract manufacturers

- Production capacity: 1–3 tons/day.

- Automated vacuum cooking, dosing, and homogenization.

- Faster batch cycles with lower manpower dependency.

- Better viscosity control and reduced batch rejection.

- Scalable layout for future expansion.

📌 Designed for consistency, speed, and repeatable quality.

Industrial Vacuumised Ketchup Plant (Fully Automatic)

Best for: Large manufacturers and national distribution.

- Production capacity: 5+ tons/day.

- Fully automated vacuum processing with PLC controls.

- Integrated CIP, pasteurization, and packaging options.

- Lowest operating cost per batch at scale.

- Strong economies of scale and long-term profitability.

📌 Built for high-volume production with maximum energy efficiency.

How to Choose the Right Configuration

- Start small if you are testing the market or replacing manual boiling.

- Move to automation if labour cost and batch variation are rising.

- Choose full automation when fuel cost, output consistency, and scale matter most.

Read More: Tomato Sauce Machine Buyers Guide 2025 with Models, Prices, and Setup Cost in India

How Vacuumised Processing Achieves Up to 50% Energy Savings

- Lowering the cooking temperatures will help lessen your thermal losses from the surroundings because steam and evaporated fuel are produced during cooking at lower temperatures.

- By eliminating excess moisture through the use of quicker concentrate removal systems during each batch cycle, you will shorten the overall cycle time for batch processing.

- Less reprocessing and rejection of the same product batch will result in more uniformity in the viscosity and flavour of the final product.

- An effective heat transfer method is to use the most efficient heating jacket and a hot vacuum environment available today.

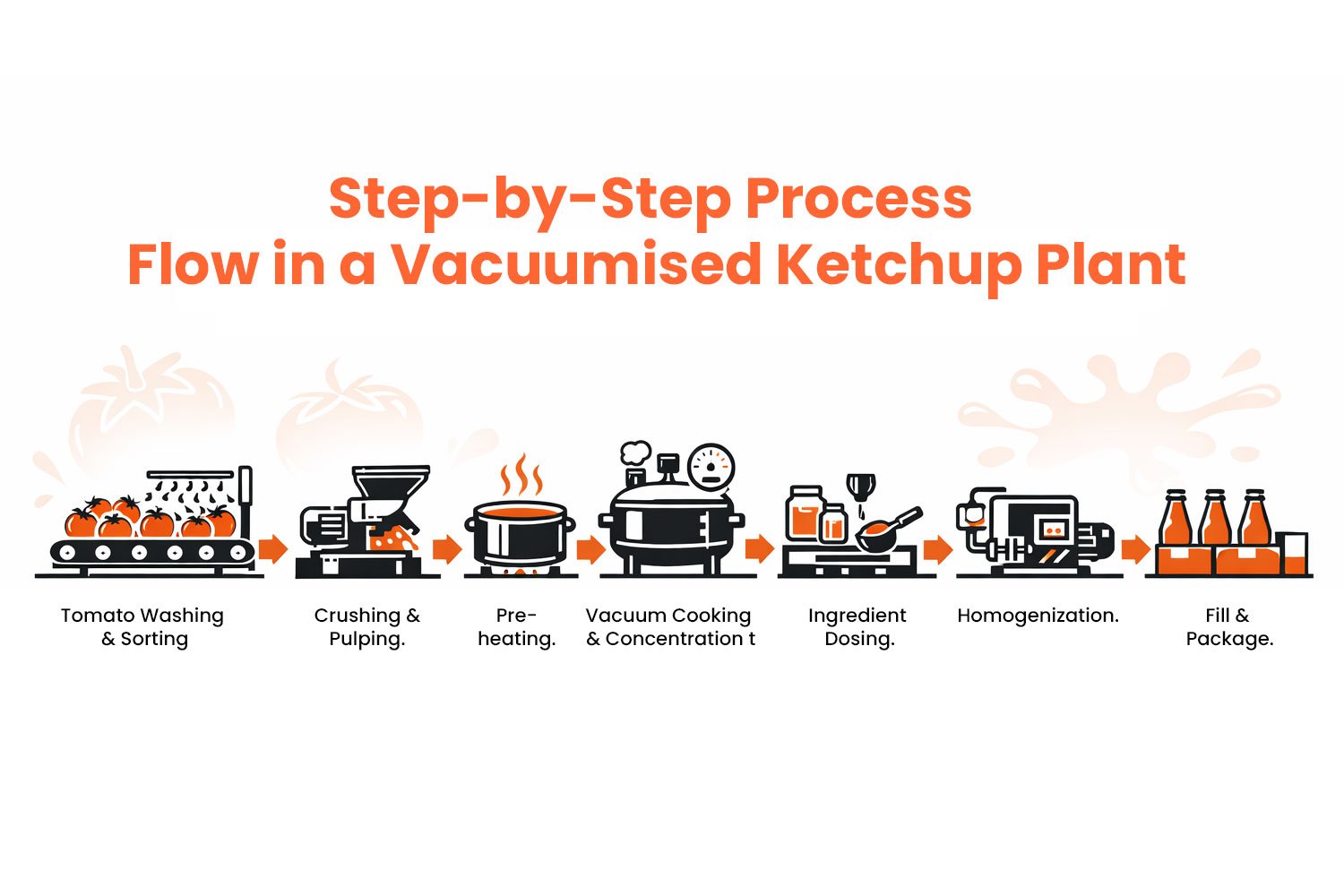

Step-by-Step Process Flow in a Vacuumised Ketchup Plant

- Tomato Washing & Sorting.

- Crushing & Pulping.

- Pre-heating.

- Vacuum Cooking & Concentration of Tomato Pulp.

- Spice/Ingredient Dosing.

- Homogenization.

- Fill & Package.

Read More: Tomato Sauce Manufacturing Machine in India: Your Partner for Scalable Production

Key Performance Metrics That Define the ROI of a Vacuumised Tomato Ketchup Plant

| Parameter | Average Range (Approx.) | What It Means for Your Business |

| Initial Investment | ₹8 Lakh – ₹75 Lakh | Depends on plant capacity and automation level |

| Production Capacity | 300 kg/day | Suitable for small manufacturers |

| Energy Consumption | 30–50% lower per batch | Direct reduction in fuel and electricity costs |

| Cooking Temperature | 55–70°C | Lower heat loss and improved flavour retention |

| Batch Processing Time | 20–35% faster | Enables more batches per day |

| Manpower Requirement | Reduced by 25–40% | Automation lowers dependency on skilled labour |

| Raw Material Yield | Higher yield per kg of tomato | Less over-cooking and evaporation loss |

| Product Rejection Rate | Significantly reduced | Consistent viscosity and taste across batches |

| Operating Cost per Batch | Lower than traditional plants | Energy and labour savings |

| Estimated Payback Period | 18–30 months | Faster ROI due to operational efficiencies |

Read More: Affordable Tomato Sauce Making Machine Price That Boosts Your Production and Profits

Conclusion: Cut Energy Costs Without Compromising Ketchup Quality

Rising fuel costs, inconsistent batches, and excessive boiling losses are common problems in traditional ketchup manufacturing. A vacuumised tomato ketchup processing plant directly addresses these issues by reducing cooking temperatures, improving heat efficiency, and delivering consistent colour, flavour, and viscosity.

For manufacturers aiming to improve margins and scale production safely, vacuumised processing offers a clear advantage: up to 50% energy savings, faster batch cycles, and a predictable ROI within 18–30 months. Whether you are upgrading from open-pan boiling or setting up a new plant, choosing the right configuration is critical to long-term profitability.

Take the Next Step: Design the Right Vacuumised Ketchup Plant

At Foodsure Machines, we help ketchup manufacturers design vacuumised plants tailored to their production capacity, budget, and growth plans. From semi-automatic setups for small processors to fully automatic industrial lines, our solutions focus on efficiency, hygiene, and consistent output.

📌 Get a clear quote, layout, and ROI estimate for your vacuumised ketchup plant.

📞 Talk to our experts today and take control of your energy costs without sacrificing product quality.

FAQs: Vacuumised Tomato Ketchup Plant

Q1. What is a vacuumised tomato ketchup plant?

A vacuumised ketchup plant cooks tomato pulp under low pressure, allowing concentration at lower temperatures.

Q2. How much energy does a vacuumised ketchup plant save?

Most plants save 30–50% energy per batch compared to traditional open boiling.

Q3. Does vacuum cooking improve ketchup colour and taste?

Yes, lower temperatures help retain natural red colour and fresh tomato flavour.

Q4. What is the cost of a vacuumised ketchup plant in India?

Prices typically range from ₹8 lakh to ₹75 lakh, depending on capacity and automation.

Q5. Is a vacuumised ketchup plant suitable for small manufacturers?

Yes, compact semi-automatic models are available for startups, FPOs, and small processors.

Q6. What production capacity do most vacuumised plants start with?

Most manufacturers start at 300–500 kg/day and scale up modularly.

Q7. How does vacuum processing reduce batch rejection?

Controlled temperature and uniform concentration ensure consistent viscosity and flavour.

Q8. What is the ROI period for a vacuumised ketchup plant?

Typical payback ranges between 18–30 months due to energy and labour savings.

Q9. Can vacuumised plants be expanded later?

Yes, most systems are modular and scalable without replacing the full line.

Q10. Are vacuumised ketchup plants FSSAI compliant?

Yes, they are designed with food-grade SS304 construction and meet FSSAI norms.