Choosing the wrong tomato ketchup plant manufacturer can increase energy costs, reduce product yield, and lock your business into inefficient equipment for years. This blog is written for food manufacturers, sauce brands, and processors planning to set up or upgrade a tomato ketchup production plant in India. Inside, you will understand how modern ketchup plants are designed, which production capacity realistically fits demand, what a tomato ketchup plant costs in 2026, and how automation, vacuum processing, and material quality directly impact long-term profitability.

Based on real manufacturing practices and industry-grade processing standards, this guide helps you evaluate manufacturers with clarity, avoid costly mistakes, and invest in a plant that delivers consistent quality, scalable output, and measurable ROI.

What Is a Tomato Ketchup Plant Manufacturer?

A tomato ketchup plant manufacturer is not just a supplier of individual machines. They design, engineer, and install the complete production line, including cooking, mixing, concentration, homogenisation, and hygienic filling.

This system-based approach ensures consistent product quality, predictable production output, and compliance with food safety standards, which are critical for commercial-scale ketchup manufacturing.

Who Typically Works With a Tomato Ketchup Plant Manufacturer?

These are not only manufacturers that sell automatic tomato sauce manufacturing machines. They deal with commercial food brands, label and contract makers of sauces, export-oriented ketchup, institutional suppliers, HoReCa clients, and regional processors, and leave behind manual or batch operations. That means they are familiar with the difficulties on all levels and can provide a system that exactly meets your requirements.

Read More: How to Make Tomato Ketchup in India Business & Manufacturing Guide

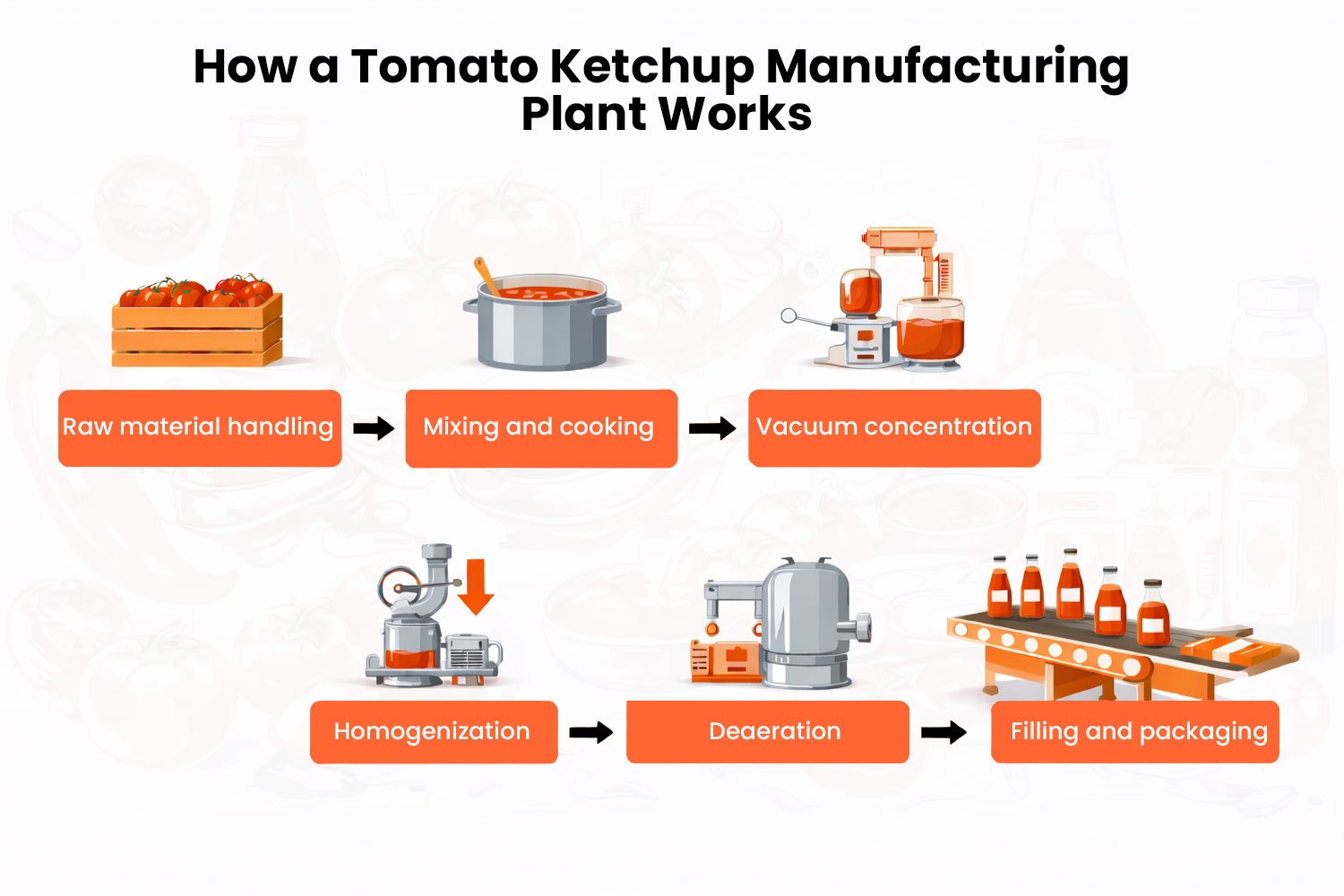

How a Tomato Ketchup Manufacturing Plant Works

The reason why a tomato puree and ketchup processing plant works is that all the steps are regulated and reproducible. We can divide it into distinct steps.

- Raw material handling: The base is made of tomato paste of 28-30 degrees Brix or fresh tomato pulp. The inline dosing of sugar, salt, vinegar, spices, and stabilisers is added. This actually translates to the fact that the recipe remains within a margin of 1-2 % every time.

- Mixing and cooking: The mixture is transferred into steam jacketed or thermic fluid kettles. The cooking is done between 85 & 95°F. Burning is avoided, and the thickness is maintained due to constant agitation.

- Vacuum concentration: Plants that are quality-oriented make use of vacuum systems. The working temperatures are reduced to approximately 55-65 °C. Colour remains vivid, taste remains pure, and power consumption can be reduced by a third or a half.

- Homogenization: The size of particles is made less than 100 microns. The outcome is the creation of a smooth texture and stable ketchup that does not separate.

- Deaeration: Pre-filling is accomplished by the removal of trapped air. This enhances oxidation resistance and prevents the weight of fill from being inconsistent.

- Filling and packaging: Hot fill or aseptic systems are used to fill the ketchup. The right configuration can be used to process bottles, pouches, sachets, and bulk packs.

Read More: Produce Premium Ketchup at Scale – Vacuumised Tomato Ketchup Plant with 50% Energy Savings

What Equipment Goes Into a Tomato Ketchup Plant

| Equipment | Function |

| Mixing Tank | Uniform blending of ingredients |

| Steam Jacketed Kettle | Controlled cooking |

| Vacuum Evaporator | Low-temperature concentration |

| Homogenizer | Texture and shelf-life stability |

| Heat Exchanger | Rapid heating and cooling |

| Filling Machine | Hygienic, accurate packaging |

| CIP System | Automated cleaning and sanitation |

Read More: Affordable Tomato Sauce Making Machine Price That Boosts Your Production and Profits

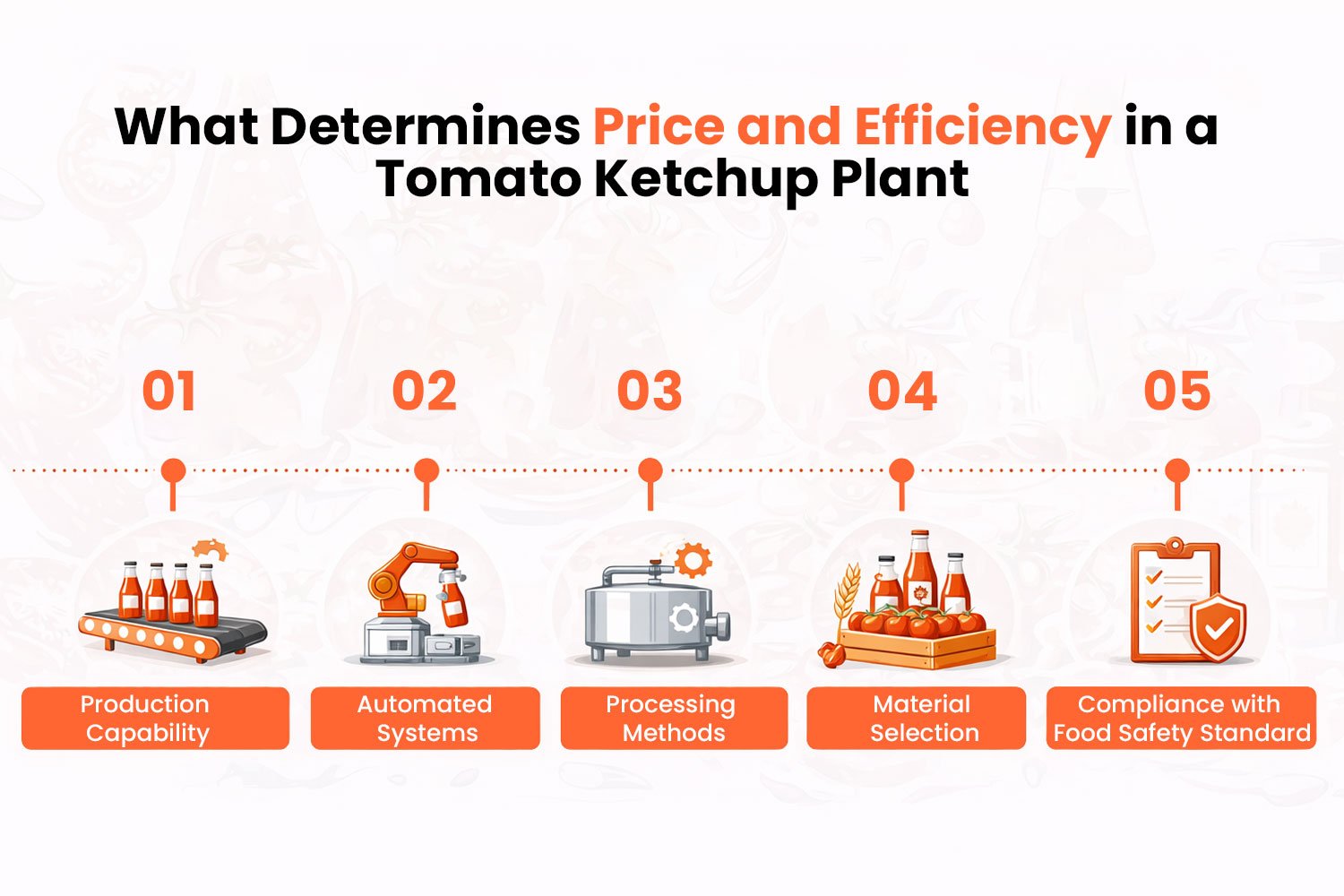

What Determines Price and Efficiency in a Complete Tomato Ketchup Plant India

- Production Capability: The smallest size of processing plant (300-500kg/hr) is intended for low-volume processing. For sustained commercial demand, a processing rate of 1-2 tonnes per hour is appropriate. For the purpose of scaling operations, plants that process 3-5 tonne/hour or greater would be considered High Capacity.

- Automated Systems: With semi-automated production lines, production relies on a combination of human labour and machinery. The ability to have fewer employees and lower entry costs is offset by the impact this type of system has on production consistency.

- Processing Methods: Processing methods that do not use vacuum processing (open kettle) typically require a lower capital investment to acquire; however, these types of processing methods require more energy to operate, offer less precision in operation, and produce a less consistent end-product.

- Material Selection: A material of SS 304 Stainless Steel has adequate corrosion resistance, provided it will be used under conditions that fall within the common uses of food product manufacturing.

- Compliance with Food Safety Standards: If a tomato ketchup machine is designed to comply with the food safety standards applicable in the region where it is designed (e.g., FSSAI, FDA, USDA, CE, EHEDG, etc.), this will make the approval process easier.

Read More: Tomato Sauce Machine Buyers Guide 2025 with Models, Prices, and Setup Cost in India

How Much Does a Tomato Ketchup Plant Cost (Machine & Plant Prices)

| Machine / Equipment | Capacity / Role | Approx. Price (₹) |

| Basic tomato sauce / ketchup making machine | Entry-level processing | ₹70,000 |

| Tomato sauce machinery (semi-automatic) | 500 kg processing | ₹70,000 |

| Industrial ketchup manufacturing machine | 100 to 1000 L batch | ₹4,00,000 |

| Tomato ketchup & sauce making machine (higher capacity) | Up to 200 kg/hr | ₹10,00,000 – ₹30,00,000 |

| Tomato sauce processing plant (automatic / larger unit) | Up to 3000 kg/hr | ₹10,00,000 |

Common Mistakes When Choosing a Tomato Ketchup Plant Manufacturer

- When you decide on a Manufacturer based solely on what you need now, you will quickly outgrow your current Manufacturer’s capabilities, creating a need to expand, which can increase in cost, disrupt your operations, or require you to make difficult decisions regarding future investments.

- While lower upfront costs for a product made from the wrong material type may seem appealing, it’s typically a guarantee for increased maintenance costs as time goes on.

- If you underestimate the amount of time required to undergo cleaning or CIP, your overall production times will be affected. In addition, your company’s labour cost will increase, and there will be a risk of contamination due to inefficient cleaning practices.

- Thinking strictly about cost when choosing an option will often lead to increased costs in the long run due to energy, labour, and maintenance. The cheapest option today is often the most expensive option tomorrow.

Conclusion

Foodsure Machines has a wide range of experience and expertise in understanding what your needs are regarding production capacity, materials, and automated equipment, so we can design your plant to achieve maximum efficiency.

Choose an Advanced Tomato Ketchup Plant Manufacturer

A tomato ketchup factory company is not only a supplier of machines

FAQ

What does a tomato ketchup plant manufacturer do?

They design and install systems that convert tomatoes into finished ketchup for bottles, pouches, or bulk packaging.

What is the typical plant capacity?

Most commercial plants operate between 500 kg and 5,000 kg per hour.

What temperature is ketchup cooked at?

Typically 85–95°C, depending on the formulation.

Can these plants produce other sauces?

Yes. With adjustments, the same line can process chilli sauce, pizza sauce, and fruit-based sauces.

What material is the equipment made of?

Food-grade stainless steel, usually SS 304 or SS 316.

Does vacuum cooking improve quality?

Yes. Lower temperatures preserve colour, flavour, and texture.

How automated are these plants?

Options range from semi-automatic to fully automated PLC-controlled systems.

How long before the investment pays off?

Most mid-sized plants recover costs within 18–36 months.

Which standards do these plants meet?

FSSAI, FDA, CE, and EHEDG standards.

How long does installation take?

Installation and commissioning typically take 6–10 weeks.

What utilities are required?

Electricity, steam or thermal fluid, water, and compressed air.

Can small brands scale with these plants?

Yes. A 500 kg/hr line provides ample room for growth without overinvestment.