Gujarat, known for its strong industrial base and progressive agro-processing ecosystem, contributing nearly 7.5% to India’s total agricultural output and over 25,000 registered food processing units as per data from the Ministry of Food Processing Industries, is rapidly emerging as a promising market for roasted makhana machines. With the increasing demand for healthy snacking options, roasted makhana, also known as fox nuts or lotus seeds, has gained massive popularity across urban and rural Gujarat. As a result, many food entrepreneurs and processing units are now looking for roasted makhana machines Gujarat to scale their operations efficiently.

Cities like Ahmedabad, Rajkot, Surat, and Vadodara are witnessing a growing demand for automated and semi-automated roasting equipment tailored for makhana. To support this shift, Foodsure Machines’ roasted makhana machines in Gujarat ensure efficient processing, energy savings, and consistent roasting quality that meets both domestic and export standards.

Why Are Roasted Makhana Machines Gujarat Important For Businesses?

Roasted makhana machines in Gujarat play an important role in makhana businesses due to their ability to make production smooth and increase the makhana’s quality.

- Increased productivity: The roasted makhana machines make the makhana production process easy, hence reducing manual labor and saving a lot of time. They help to handle large-scale operations and roast uniform quantities of makhana in each batch, which helps to meet the growing market demands.

- Consistent makhana quality: Getting uniform roasting and puffing of makhana is tough with traditional methods. Roasted makhana machines in Gujarat control the temperature and distribute even heat, which results in consistent crispiness and high quality of makhana.

- Cost-friendly: By reducing labor requirements and energy consumption, roasted makhana making machine Gujarat lower the operational costs for your business, as their energy-efficient designs save a lot of electricity while maintaining high production of makhana.

- Increased Product Safety: Made with food-grade stainless steel (SS 304), these machines guarantee durability and compliance with food safety regulations so that the final product is hygienic and safe for consumption.

Read More: Makhana Machine Trends 2025: Industry Growth & New Opportunities

Types Of Roasted Makhana Machines Gujarat

| Machine Type | Target Users | Features | Benefits |

| Fully Automatic Makhana Roaster Machines | Large-scale manufactures | Handle the entire roasting process, from raw material feeding and roasting to cooling and packaging. High-speed, continuous operation. |

Maximizes production capacity. Consistent quality. Reduced labor requirement. |

| Semi-Automatic Makhana Roaster Machines | Medium-sized companies | It’s a perfect blend of automation and manual labor. Efficient roasting while allowing operators to look at and manage the process. |

Cost-effective Scalable for growing businesses Balanced control and automation |

| Manual Makhana Roaster Machines | Start-ups or small businesses | Easy operation and maintenance. Batch-based roasting with consistent quality |

Affordable entry point into the makhana processing industry. Ideal for small batch production |

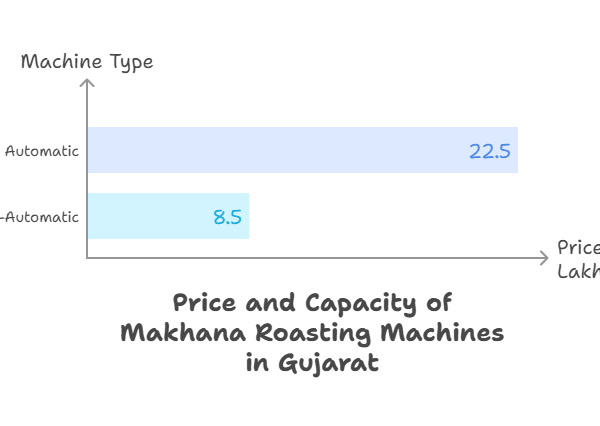

Roasted Makhana Machines Price in Gujarat

The makhana manufacturers in Gujarat differ based on their automation level—manual, semi-automatic, or fully automatic. These costs vary as:

- Fully automatic roasted makhana machine: ₹ 22-23 lakhs (approx.), which has a capacity of up to 100 kg/hr

- Semi-automatic roasted makhana machine: ₹ 8-9 lakhs (approx.), which has a capacity of 50 kg per batch.

Read More: Makhana Machine Cost in India- ROI Analysis for Manufacturers

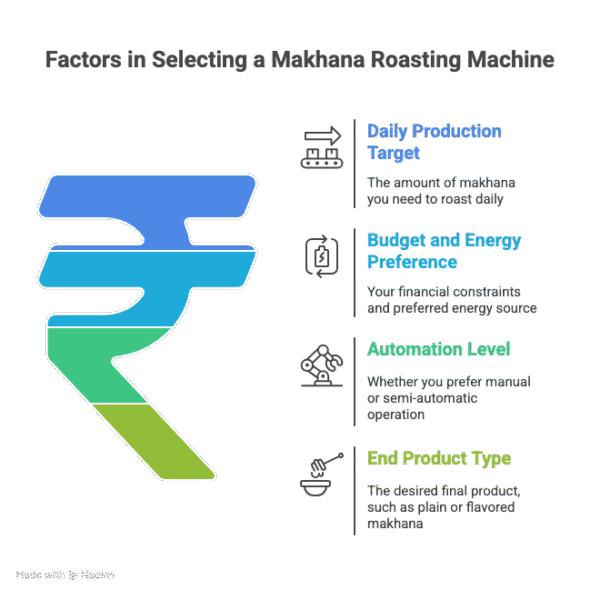

How to Choose Makhana Roasting Machine in Gujarat?

Choosing the right machine depends on:

- Your daily production target

- Your budget and energy preference (LPG/electric/diesel)

- Whether you want manual or semi-automatic systems

- The type of end product (plain, flavored, oil-roasted, or oil-free)

Process of Roasted Makhana Machines Gujarat

The process of the roasted makhana machines is not limited to roasting; you have to undergo the whole process of makhana, from grading to packaging. The whole makhana processing includes the following:

- Grading and Cleaning

Before roasting, the raw makhana needs to be cleaned to remove impurities like dust or stones. Foodsure Machines’ Automatic Makhana Grader machines guarantee uniform size sorting, hygienic processing, and higher efficiency in roasting.

Specifications

- Contact parts are made of Stainless Steel 304 (SS304) and non-contact parts of Stainless Steel 202 (SS202), assuring longer durability.

- Designed for separating materials by size, effectively sorting them from larger to smaller sizes.

- Commonly used in environments where hygiene is important, such as in food processing equipment and medical instruments.

- It generally power loads 0.75 KW.

- Roasting

Makhana roasting is an important step in the whole process. Foodsure Machines’ Makhana Rotary Roaster helps in uniform makhana roasting that improves the taste and shelf life of makhana while reducing manual labor.

Specifications

- Capacity of 80-100 kg/ 30 Minutes.

- Contact parts are made of Stainless Steel 304 16 Gauge with a thickness of 18 to 20 mm, and its non-contact parts are Stainless Steel 202.

- The roaster controls rotating drum technology to roast makhana evenly without burning it.

- Fox Nut Roasting Machine helps in oil-free or minimal oil roasting options for makhana and maintains the uniform color and crispiness of every batch.

- Flavoring and Seasoning

After the makhana roasting, it’s important to add flavors and seasonings to make the makhana more tasty for your consumer. But the flavor and seasoning of makhana doesn’t stick only to spices; in fact, it’s more extended to this! Foodsure Machines offers flavors and seasonings like achari lemon, peri peri, chocolate, cheese & jalapeno, indian masala, tandoori, and more.

Specifications

- The drum is made of Stainless Steel-304 with other construction of Stainless Steel-202.

- The use of Stainless Steel-304 and Stainless Steel-202 materials provides long-lasting performance and resistance to corrosion.

- It has an additional feature of extra fitting of powder seasoning sprinkler.

- The tumbler’s design and additional seasoning sprinkler ensure even distribution of seasoning, resulting in consistently flavored products.

- Packaging

Makhana packaging is the most important step in the whole makhana process. Foodsure Machines’ makhana packaging machines help to pack them in air-tight, moisture-proof pouches to maintain their shelf life, freshness, and quality. Our semi-automatic and fully automatic packaging lines offer custom packaging sizes for your makhana business.

Specifications

- Up to 40 pouches per minute (actual speed depends on product type, weight, and the number of heads used)

- The use of SS304 in contact parts ensures that the machine meets the stringent hygiene standards required in the food industry.

- High packing speed optimizes production efficiency, reducing downtime and increasing output.

- The combination of SS202 and SS304 materials ensures the machine’s longevity and reliable performance.

Read More: The Complete Guide on How to Make Makhana for Commercial Success

Why Foodsure Machines Are the Best for Roasted Makhana Machines in Gujarat?

- Complete roasted makhana machine services in Gujarat

We offer installation, training, maintenance, and after-sales service for roasted makhana processing machines in Gujarat. Whether you’re located in Ahmedabad, Rajkot, Vadodara, Bhavnagar, or Jamnagar, our experts are just a call away for your business.

- Modified solutions for all production scales

Whether serving a small village cooperative processing 500 kg monthly or an industrial operation handling 8+ tons, Foodsure Machines offer scaled solutions. This range allows businesses to invest in technology that matches their current needs while providing clear upgrade paths as they grow.

- High-quality roasted makhana makhana

Foodsure Machines produce high-quality makhana roasted machine that meets international food safety standards. The stainless steel construction (food-grade SS304/SS316) and temperature control systems ensure hygienic processing without compromising the nutritional value that makes makhana a superfood in Gujarat.

- Affordable Pricing

We provide excellent value for your investment. Our fox nut processing machine are affordable to ensure you get the best return on your investment. We offer high-quality roasted makhana machines in Gujarat at lower prices, making it easier for businesses of all sizes to enter the makhana processing industry.

- Expert Training and Consultation

We provide expert training and consultation services to help you get the most out of your investment. Our team of professionals will guide you through the setup, operation, and maintenance of your roasted makhana machines, guaranteeing proper performance.

Contact Foodsure Machines To Have The Best Roasted Makhana Machines In Gujarat!

Foodsure Machines is your one-stop solution for the 25,000 registered food processing units as per data from the Ministry of Food Processing Industries in Gujarat that are modified to meet your business needs. From installati on to after-sales, you have full support and guidance from our side. Our roasted makhana machines Gujarat help you maximize makhana production, guarantee consistency, and increase profits that are made for efficiency and durability. We provide our services in Ahmedabad, Rajkot, and all over Gujarat.

Enquire Now for Roasted Makhana Machines in Gujarat!

Reach out to us anytime via phone or email.

FAQ

1. Which company makes the best roasted makhana machines in Gujarat?

Several Gujarat-based manufacturers offer reliable, high-efficiency makhana roasting machines.

2. What is the price of a roasted makhana machine in Gujarat?

Basic roasting machines in Gujarat typically start from affordable small-scale models.

3. Which state leads in producing roasted makhana machines?

Gujarat is one of the key states known for manufacturing makhana processing equipment.

4. Is the roasted makhana machine business profitable?

Yes, profit margins are strong due to rising demand for roasted makhana snacks.

5. How much does 1 kg of roasted makhana processing cost using machines?

Machine-based roasting significantly reduces per-kg processing cost.

6. Which machine is used for roasting makhana?

Automatic hot-air or drum roaster machines are used for roasting makhana.

7. Which city in Gujarat is known for roasted makhana machines?

Cities like Ahmedabad and Rajkot are known for food-processing machinery manufacturing.

8. How to identify a good roasted makhana machine?

Look for machines with uniform roasting, adjustable heat control, and durable build.

9. Who is the largest supplier of roasted makhana machines in Gujarat?

Multiple established manufacturers in Gujarat supply machines across India.

10. Who is the largest exporter of roasted makhana machines from Gujarat?

Several Gujarat-based machinery companies export roasting equipment globally.

11. Can I use a roasted makhana machine daily?

Yes, commercial roasting machines are designed for continuous daily operation.

12. Which is the No. 1 roasted makhana machine type in Gujarat?

Automatic hot-air roasters are the most preferred due to efficiency and consistency.