If you’re an entrepreneur or managing a food enterprise, you have witnessed the speed growth of the Protein Bar category in India. As more people embrace healthy snacks on a daily basis, the competition in this category has increased dramatically. The variable that differentiates each successful protein/energy bar brand is not just the recipe. It’s the machine that makes the protein bars. This article will examine the Top Protein Bar Machine Manufacturer in India (2025) to help us understand what makes their equipment the primary choice for many of the larger food companies in India.

Best Protein Bar Machine Manufacturers You Can Trust

1) Foodsure Machines

Why we lead:

- SS304 food-grade stainless steel: We are at the leading because we care about hygiene and safety. Our machines are made fully from SS304 food-grade stainless steel. To make sure that food ingredients won’t stick and bacteria cannot live on them.

- Servo-guillotine cutters: Every bar is the same weight. That means your product claims about protein, calories, and nutrition remain valid.

- Standard machines: Managing throughput will be very suitable for you as well. Our standard machines can be delivered within 30 days of the order and advance payment being completed.

2) ABC Agro & Food Machine (Coimbatore)

Why They Lead

- Strength: They have a set of sheeting and cutting machines, and some experience with traditional bars like chikki. Their machines are designed for use with granola and protein bars.

- Good Fit: Budget projects and facilities, adjusting the individual modules.

3) Snactek (Pune)

Why they lead:

- Strength: Snactek makes strong strengthening systems with their slitting and guillotine machines. They also have sheeting machines that would work with customized lines.

- Good Fit: Consumers building modular systems around a mixing system and cooling overhead.

4) VEC (Chocolate & Bar Equipment)

- Strength: Although VEC specializes in chocolate, it also makes granola and protein bar machines. One area shines, and that is when coating production and handling mixtures are in the design.

- Good Fit: Any line that needs chocolate, from day one.

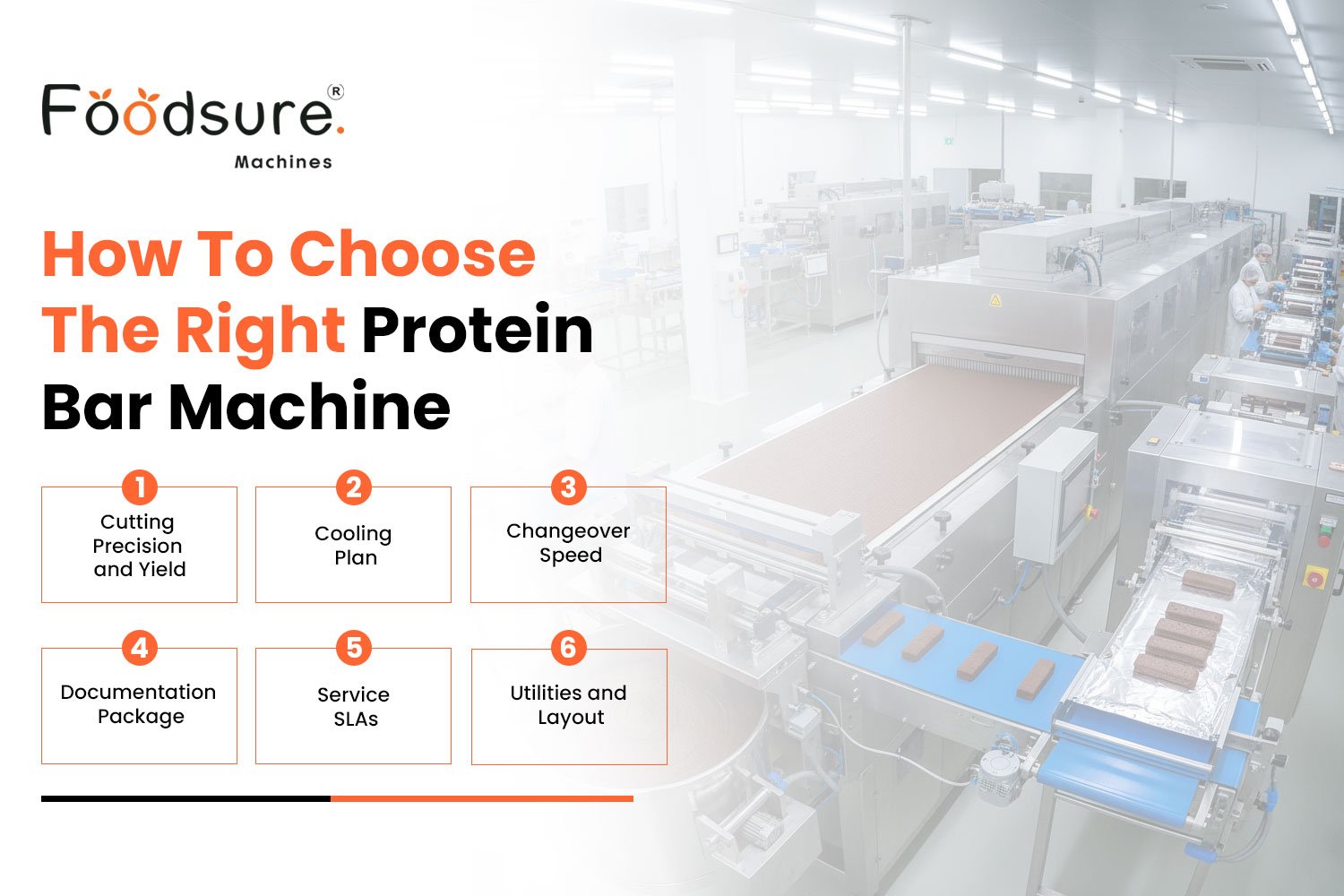

How to Choose the Right Protein Bar Machine

- Cutting Precision and Yield: Request specifications for the servos and cut-tolerance (±1 mm), to make sure all of the bars will be consistently weighted and keep the margin of production even.

- Cooling Plan: Find out whether the machine uses chilled cooling (4-10 °C). If in a warm situation and using any covered products, this is especially important, based on your situation.

- Changeover Speed: Look for specifics such as quick-release belts and tool-less guides. Ask for a demo video of a real SKU in a similar vein to see for yourself how fast it is.

- Documentation Package: Check if the supplier provides the DQ/IQ/OQ reports, FAT/SAT records, and SOPs for the machine. This type of confidence up front will save weeks of audit time.

- Service SLAs: Ask for timelines on installation, on-site training, help via WhatsApp/video, and service lead time. Knowing what to expect is important for maintaining safe production flow.

- Utilities and Layout: Request a layout, then a utilities checklist, to include power (kW), compressed air (LPM), refrigeration (TR), drains, and hygiene zoning. You want to have confidence that even your facility is ready and compliant.

Core Specifications for a Standard Protein Production Line

- Capacity: 50, 100, or 200 kg/hr systems with slab former + calibrator, slitter + servo-guillotine, chilled tunnel.

- Add-ons: Optional flow-wrap with coder, metal detector, checkweigher; chocolate enrober or decorator for premium SKUs, etc.

- Controls: PLC with 7–10″ HMI and recipe memory, VFDs, servo-driven cutter, interlocks, and emergency stops.

- Material of Construction (MOC): SS304 for all contact parts, passivated welds, and food-grade belts.

Why Foodsure Machines Are the Trusted Choice for Health-Focused Food Businesses

With over 13 years of practical experience, Foodsure Machines places a great focus on hygiene, consistency, and efficiency. The machines will be capable of delivering mixtures-cutting with correctness, and quickly fulfilling your custom order. You will have the training and support needed to start production with confidence.

FAQ

Q1: Can you start with less than 50 L?

Ans: Yes, mixer, binder kettle, slab former (or extruder), basic cooling, guillotine (semi/auto), then you could add a slitter, wrapper, QA, and Amazon warehouse.

Q2Is it better to extruder/or a slab former?

Ans: Generally, a pure date/no-bake would prefer an extruder, high inclusions/granola hybrids would prefer a slab with a slitter, guillotine. Many operations have both.

Q3: What is the lead time for dispatch?

Ans: For paint and layouts, materials are approximately lead time for a typical configuration from industry tier one, now typically target 30 days (from time purchase order, advance, site conditions).