The mess inside most industrial makhana grader units is not about lazy staff or untidy packaging. It’s a system problem. When an industrial makhana grader is manual, the whole operation slips into chaos. Makhana of all sizes get mixed up, roasting becomes guessing, and the results are either under-popped or burnt. That way, you lose a product before it even hits the market. That’s not due to lack of effort; it’s because of manual grading machine by hand that just can’t deliver that level of Precision Makhana Grading Machine. What this means is: until grading becomes scientific and reliable, every batch will carry too much risk and too little reward. This blog will help you to overcome that chaos by showing exactly how the right precision makhana grading machine for export changes everything.

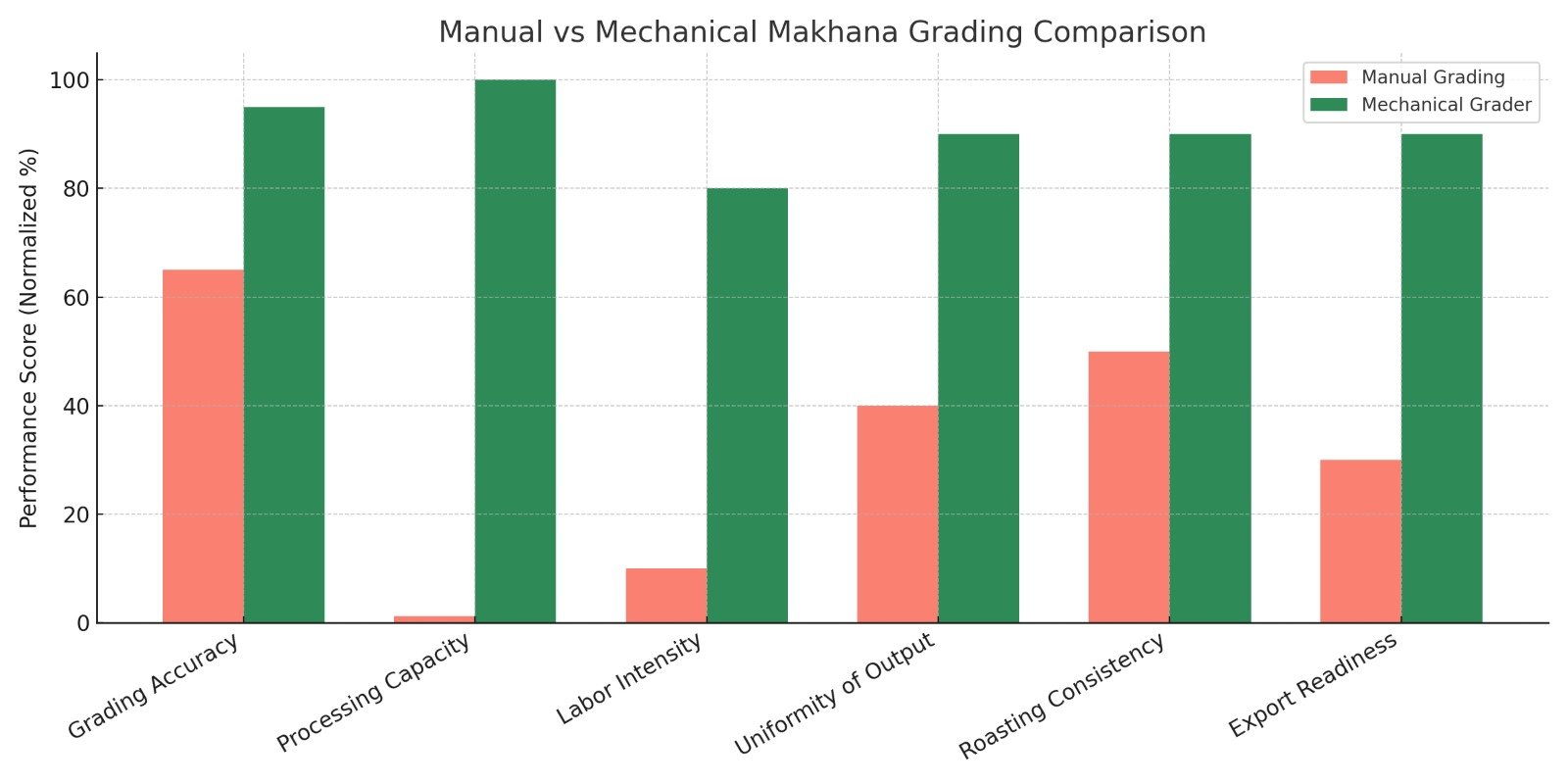

Grading Effectiveness & Production Capacity Of Makhana Grader vs. Manual Grading

Now, you can see it clearly in the numbers how precision makhana grading machine doesn’t just speed things up, but also changes how your entire operation runs. The India makhana market size reached INR 8.5 Billion in 2024. Looking forward, IMARC Group expects the market to reach INR 19.6 Billion by 2033, exhibiting a growth rate (CAGR) of 9.22% during 2025-2033. Accuracy shoots up, labor demand drops, and your product finally hits the standards serious buyers expect. What this really means is: less chaos, fewer rejections, and better margins.

How Inconsistency Affects Makhana Business Outcomes

Buyers drive prices down: When your commercial makhana grading plant for export is not consistent, buyers can’t count on getting what they need. That makes negotiation easy for them and painful for you. They will push the price lower or walk away from the deal entirely. While leaving you with stock that either sells cheap or doesn’t sell at all.

Packaging suffers: Makhana, which is all over the place in size, looks messy and unprofessional on the shelf. No matter how good it tastes, uneven presentation kills the premium feel. As you know, the shelves are crowded if you don’t get a second chance to look like a serious brand.

Roasting becomes a risk: Small kernels pop fast, big ones take time. Mix them all, and you either burn some or under-roast others. That means more waste, less consistency, and a final product that doesn’t live up to expectations. If customers notice that inconsistency, then they don’t come back.

Export is risky at best: Did you know that global buyers are strict? They check size, texture, and even appearance. They want everything to match. If you are not using a proper commercial precision grading equipment for export, then rejections become routine. And every rejected shipment means money lost, time wasted, and trust ruined.

Why Precision Grading Is Not Optional Anymore

Here’s the thing: Precision makhana grading machine isn’t just a nice-to-have anymore. It’s the baseline if you are serious about scaling your commercial makhana grading machine and staying in line with the market demand. Especially in premium retail and export markets, expect tight consistency in size and quality.

One bad batch, and you risk losing their trust and their orders. A solid precision makhana grading machine fixes that. It brings every batch up to specifications, builds buyer confidence, and keeps the repeat business flowing. It also puts you in control of your pricing. When you know your product is consistently top-grade, you don’t have to wait for the market to decide your value. You can set it yourself.

Precision makhana machine tightens up your whole operation. Roasting becomes more improved, waste drops, packaging gets easier, and your team spends less time fixing problems and more time moving forward. If you want to grow, sell smarter, and run a cleaner, more profitable unit, the makhana grading system is not optional. It’s the move.

This Is What Consistent Grading Actually Looks Like

A good food grade precision size grader doesn’t just sort makhana. It unlocks control, consistency, and pricing power. And that’s the difference between running a unit that survives and one that grows.

No More Last-Minute Rashing: The machine does the sorting in one clean run. You are not stuck with workers frantically hand-picking sizes before dispatch. The industrial makhana grader handles it all faster, more accurately, and without the stress.

Clear, Accurate Size Separation: Every kernel goes exactly where it belongs: small, medium, large, and even finer sub-sizes if you need them. No overlaps, no confusion, and you get clean batches ready for roasting or packaging right off the line.

Roasting That’s Predictable: Even sizes roast evenly. That means no bitter, half-burnt makhana and no undercooked bits either. Just a crisp, reliable product every time, so the taste and texture stay consistent across every packet.

Pricing With Confidence: When you know how much top-grade makhana you are producing, you can price it properly. Whether you are creating premium product lines or negotiating with buyers, you are not guessing; you will have data and clarity on your side.

Choose Foodsure Machines, From Chaos To Control

Precision makhana grading machine isn’t just about sorting makhana. It’s about running a business that’s predictable, profitable, and built to grow. At foodsure Machines, we build a makhana grading system that gives you exactly that. You get clean batches, consistent size separation, fewer rejections, and a product you can price with confidence. No more last-minute fixes or wasted stock. Just smooth operations and makhana that’s ready for serious markets. Ready to upgrade your grading? Talk to Foodsure Machines and take control of your makhana line today!

Ready to Start Your Roasted Makhana Machine Journey?

Connect with us online for quick support.

Frequently Asked Questions

How much time and product do you lose every month because of inconsistent grading or manual sorting?

It’s probably more than you are tracking. Manual grading slows everything down and still sends mixed sizes into roasting. That leads to more waste, more rework, and less sellable product.

If your grading sorted every batch to export quality standards, how would that change your pricing and buyer conversations?

You would stop hoping for better prices and start setting them. Clean, consistent grading gives you confidence and stronger control during buyer negotiations.

What’s holding your unit back from running smoother, faster, and with fewer rejections?

In most cases, it starts with grading. Once grading is fixed, roasting, packaging, and pricing all begin to run efficiently.

Which grade of makhana is best for grading machines?

Large-size, premium export-grade makhana is considered the best for machine grading.

What machine is used for makhana grading?

A multi-deck makhana grading machine with size-based separators is commonly used.

What is the 4-grading system in makhana?

It separates makhana into four sizes: small, medium, large, and super-large.

What is the price of a makhana grader machine?

Makhana grading machines generally cost between ₹1.5 lakh and ₹6 lakh, depending on capacity and automation level.

What are the two types of makhana grading?

Manual grading and machine-based automatic grading are the two main types.

How much does it cost to use a grader per hour?

Operating cost is usually around ₹80–₹150 per hour, including power and basic labour.

How is makhana grading calculated?

Grading is calculated based on kernel size, uniformity, and defect removal.

How many types of makhana grading machines are there?

Common types include vibratory graders, rotary graders, and multi-deck automatic graders.

How many types of grading are done in makhana?

Usually 3 to 5 grades are created, depending on the machine configuration.