Packaging issues in makhana production can harm the reputations and finances of small businesses. Customers become irritated and initiate return items due to leaking packets, crushed makhana, and uneven pouch weights. The majority of these packaging problems originate upstream, during the roasting, cooling, or seasoning phases, and are not caused by the makhana packaging machine itself.

Packaging Issues in Makhana Production: Common Problems You Can’t Ignore

Producers of makhana often blame their losses on the packaging stage; however, the real problems generally take place earlier in the process. If these kinds of problems are not addressed properly, they lead to wastage of useful materials, higher labour costs, and unsatisfied customers. Common packaging issues in makhana production are an opportunity to identify the weak points in your line and take proactive measures to prevent damage accumulation.

The Main Indicators of Packaging Malfunctions

- Pouches leaking oil or moisture – This is due to uneven seasoning or residual heat that enters the packaging machine. Leaks not only visually spoil the product, but they also cause deterioration.

- Makhana that is crushed or broken in packs – This is generally due to fluctuating output in the roaster, incorrect cooling, or rough handling during filling.

- Pouch weight that is not uniform – This leads to complaints and regulatory issues, which are usually associated with the batch feeding method or inconsistent hopper flow.

- Seal breakdown during storage or transport – This is often caused by warm makhana, inferior film quality, or high moisture content.

Why Packaging Machines Alone Can’t Solve Quality Issues in Makhana Production

The packaging issues in makhana production cannot be attributed to sealed. The raw material that enters the makhana packaging line must be consistent in order to ensure the efficiency of the packaging line.

- Unstable Roaster Output: Non-uniform puffing that is not uniform will result in varying bulk densities. This will cause the volumetric fillers to vary in weight and also produce bigger popped kernels, which will be crushed by the sealing jaws.

- The Cooling Gap: Once the makhana is packed before it reaches the normal temperature, the moisture migration will be triggered by the residual heat. This will lead to condensation forming inside the pouch, hence causing spoilage and seal failure.

- Uncontrolled Manual Seasoning: The process of hand-seasoning results in uneven distribution of oil. The extra oil on the product’s surface will interfere with the closing process, and the hermetic bond won’t be made. Leaks will happen as a result.

- Batch vs. Continuous Flow Mismatch: If there is no automated feeding, the packaging unit will experience an unreliable material supply. This starve-and-surge cycle will increase mechanical wear and also prevent the makhana making machine from maintaining the steady internal pressure that is required for optimal bag forming.

The Hidden Costs of Poor Machine Integration and Quality Issues in Makhana Production

Inaccurate machine integration is not only a primary factor that reduces production, but also steals profits every month in a silent way. When roasting, cooling, seasoning, and packaging occur simultaneously, losses are shared among labour, materials, and the brand’s credibility in the market. These costs are seldom reported individually, but when combined, they are a major reason for the shrinking of margins and the postponement of production plans.

| Cost Area | What Causes the Loss | Estimated Monthly Cost (₹) | Annual Impact (₹) |

|---|---|---|---|

| Extra labour for rework & repacking | Seal failure, leakage, weight mismatch | ₹15,000 – ₹25,000 | ₹1.8 – ₹3.0 lakh |

| Packaging film wastage | Rejected or leaking pouches | ₹8,000 – ₹15,000 | ₹1.0 – ₹1.8 lakh |

| Increased rejects & returns | Crushed makhana, oil leakage | ₹12,000 – ₹20,000 | ₹1.4 – ₹2.4 lakh |

| Distributor & retailer complaints | Poor shelf quality, leakage | ₹5,000 – ₹10,000 | ₹60,000 – ₹1.2 lakh |

| Brand trust erosion | Discounts, replacements, lost orders | ₹10,000 – ₹20,000 | ₹1.2 – ₹2.4 lakh |

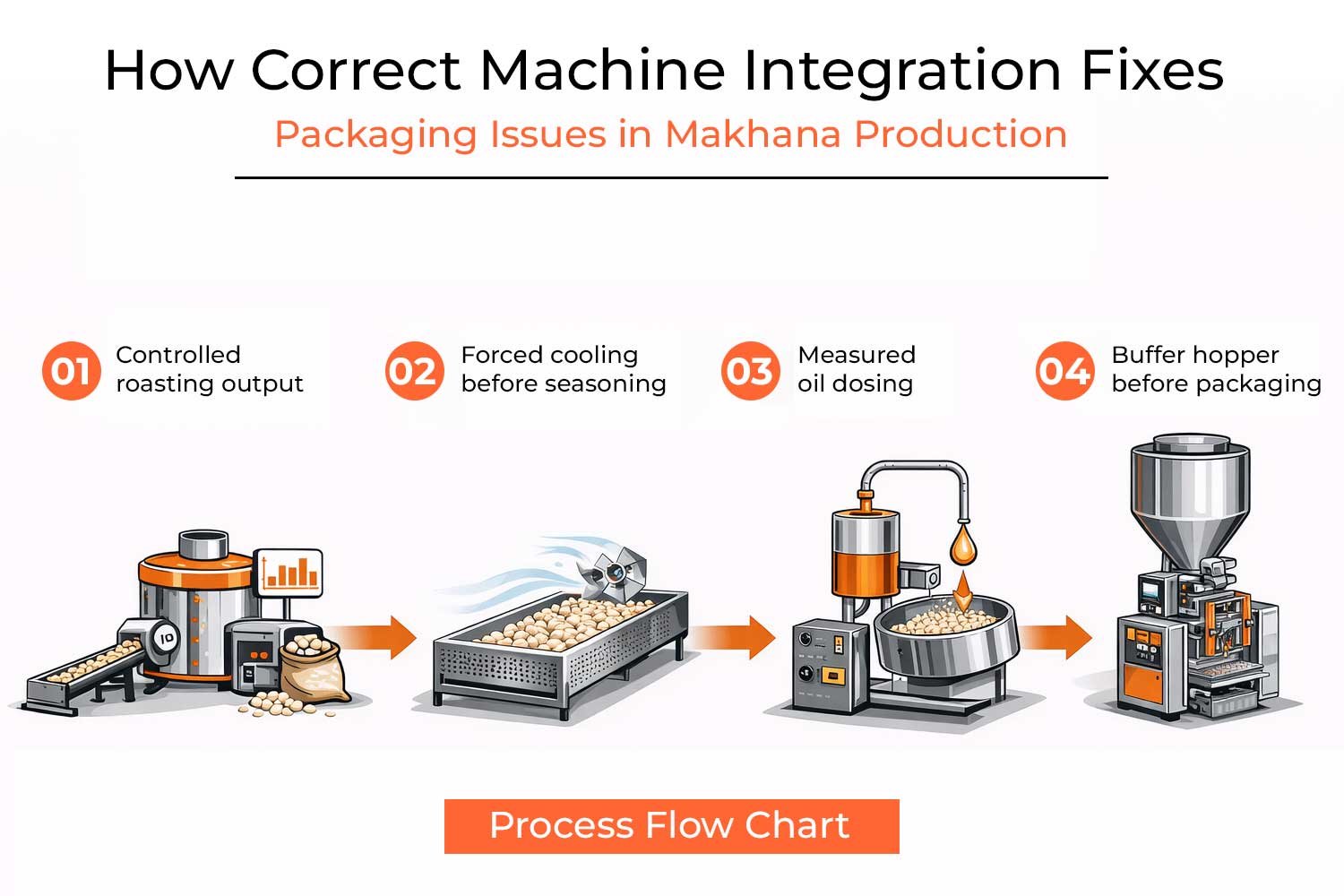

How Correct Machine Integration Fixes Packaging Issues in Makhana Production

The stability of packaging will be greatly improved if not only the upstream makhana processing machines were designed for isolated upgrades, but also if the whole system worked as one. The correct integration will ensure that the product entering the makhana airtight packaging machine is uniform in terms of moisture content, and it will be in the form of powder, which eliminates the main causes of leakage, breakages, and seal failures.

Steps for Proper Flow

- Controlled roasting output – Uniform puff size and controlled moisture result in constant fill weight and lower crushing during packaging.

- Forced cooling before seasoning – Slow down the temperature change, and the pouches will not absorb any moisture, which in turn will not affect the seal and will not shorten the shelf life.

- Measured oil dosing – The application of oil is done with great accuracy, which in turn prevents uneven coating and ensures that oil is not present on the surface, thereby preventing leakage and contamination of the film.

- Buffer hopper before packaging – Keeps product flow constant, thus eliminating the cases of feeds being starved or overloads that lead to weight variation and seal defects.

Conclusion

At Foodsure Machines, we consider packaging errors as integration issues rather than machine problems. Our method is based on ensuring that the steps of roasting, cooling, seasoning, and packaging all occur simultaneously. When our systems work together, there are fewer problems with packaging, the quality is better, and production is more reliable in the long run.

FAQ

What causes packaging issues in makhana production?

Most failures start upstream. Uneven roasting, incomplete cooling, and inconsistent seasoning create unstable product long before it reaches the pouch.

Why do makhana packets leak oil after sealing?

Excess surface oil or trapped heat weakens seals. When oil and warmth stay inside the pack, leakage becomes almost unavoidable.

Can packaging machines alone fix makhana packaging problems?

No. Packaging machines can only handle what they receive. If flow and quality are unstable earlier in the line, problems repeat after packing.

How does cooling affect the packaging quality of makhana?

Warm makhana releases moisture after sealing. This condensation weakens seals and quietly shortens shelf life.

When should a makhana unit fix machine integration?

As soon as rejects, complaints, or rework begin increasing. Delaying integration only makes losses harder to control.