Majorly, mayonnaise brands don’t fail because of taste; they fail because of poor plant design. In India, demand for mayonnaise has increased threefold in the last five years, yet 60% of small manufacturers struggle with inconsistent quality and high costs. So what separates profitable plants from struggling ones? This guide breaks down the exact setup, machines, and ROI path that works.

Why Choosing the Right Mayonnaise Manufacturing Plant Matters

Selecting the best producer of the Mayonnaise Manufacturing Plant is not a matter of branding. It’s an operational choice that determines how well or poorly your business operates.

- Everything starts to fail if the mayonnaise production line is unable to provide the same texture, viscosity, and stability daily. Proper homogenisers and high-shear mixers are required, which will form the basis of a stable emulsion. If you get them wrong, you will have rejected batches, watery texture, and separation. Before anyone notices, the loss has already increased.

- The same rules apply for Food safety. This actually refers to food-grade stainless steel( usually SS304 or SS316L) and CIP systems that truly clean as meant.

- Production is not the initial thing that suffers when mayonnaise-making machines stop working in the middle of a shift; it also impacts the changes in scheduled labour.

- A quality manufacturer helps in assisting while selecting between batches or continuous systems, while maintaining an appropriate degree of automation to prevent future, expensive rebuilds due to growth.

Read More: How to Start a Mayonnaise Manufacturing Business

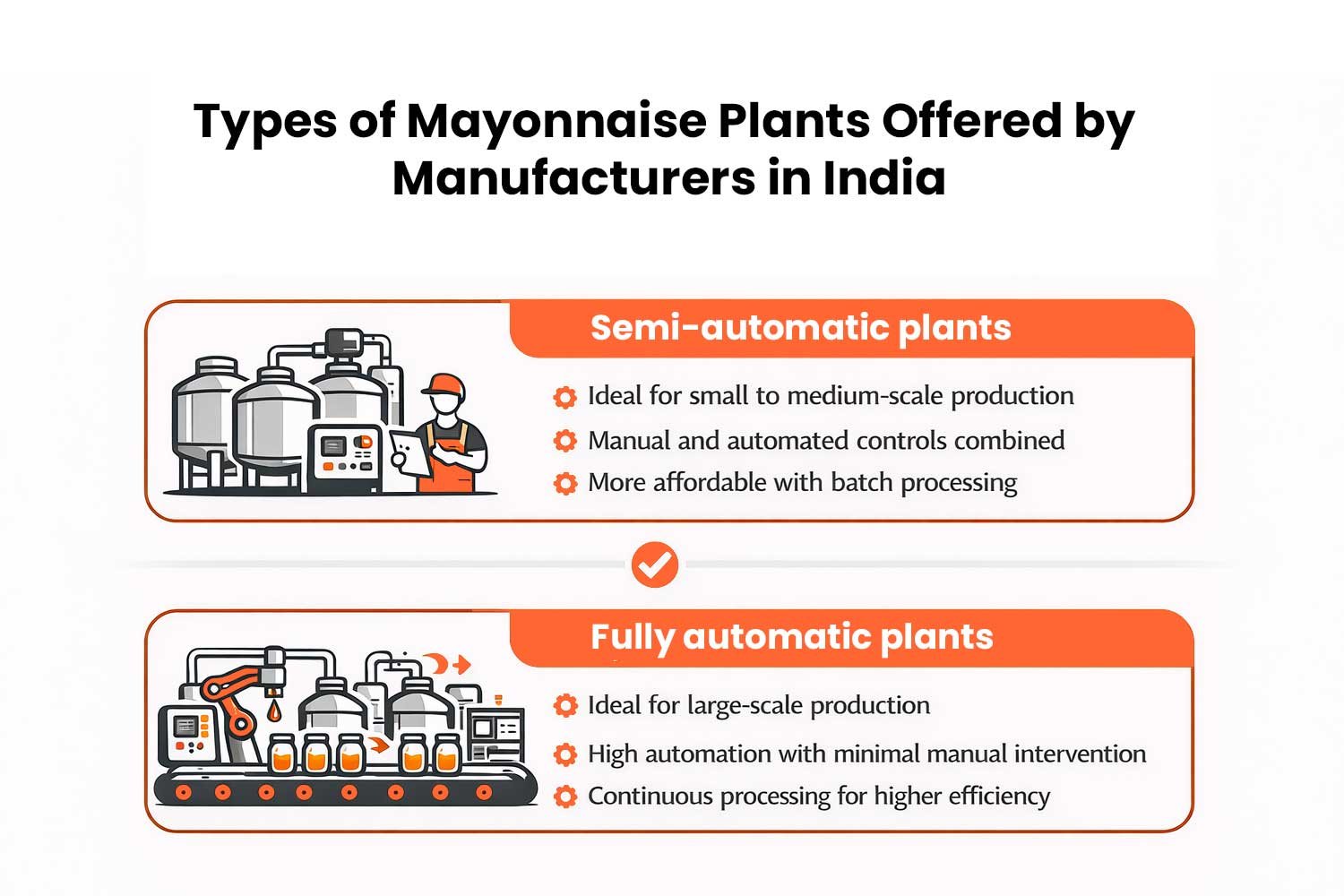

Types of Mayonnaise Plants Offered by Manufacturers in India

- Semi-automatic plants: A practical choice for startups and small manufacturers. Ingredient loading is done manually. However, mixing and emulsification are automated processes. While you’re still learning out the market, you save money up front and maintain the flexibility to modify recipes.

- Fully automatic plants: By automating the dosing, mixing, emulsifying, and discharging of the materials. Automation allows you to create a more uniform product as well as improve hygiene by removing many of the human variables.

Read More: 2025 Buyer’s Guide: Fully vs Semi-Automatic Mayonnaise Machines – Which One Wins?

Typical Cost and Pricing Overview for a Mayonnaise Manufacturing Plant

| Plant Type | Daily Production Capacity | Approx. Plant Cost (₹) | Avg. Production Cost per Kg (₹) | Avg. Wholesale Selling Price per Kg (₹) |

| Semi-Automatic (Pilot) | 200–300 kg/day | 8–12 Lakh | 90–110 | 130–160 |

| Semi-Automatic (Medium) | 500–700 kg/day | 15–22 Lakh | 85–105 | 130–170 |

| Fully Automatic (Medium) | 1,000–1,500 kg/day | 30–45 Lakh | 75–95 | 140–180 |

| Fully Automatic (Industrial) | 2,000–3,000 kg/day | 55–75 Lakh | 70–90 | 150–190 |

Read More: Buy Mayonnaise Machine in India – 2025 Prices, Specs & Best Models

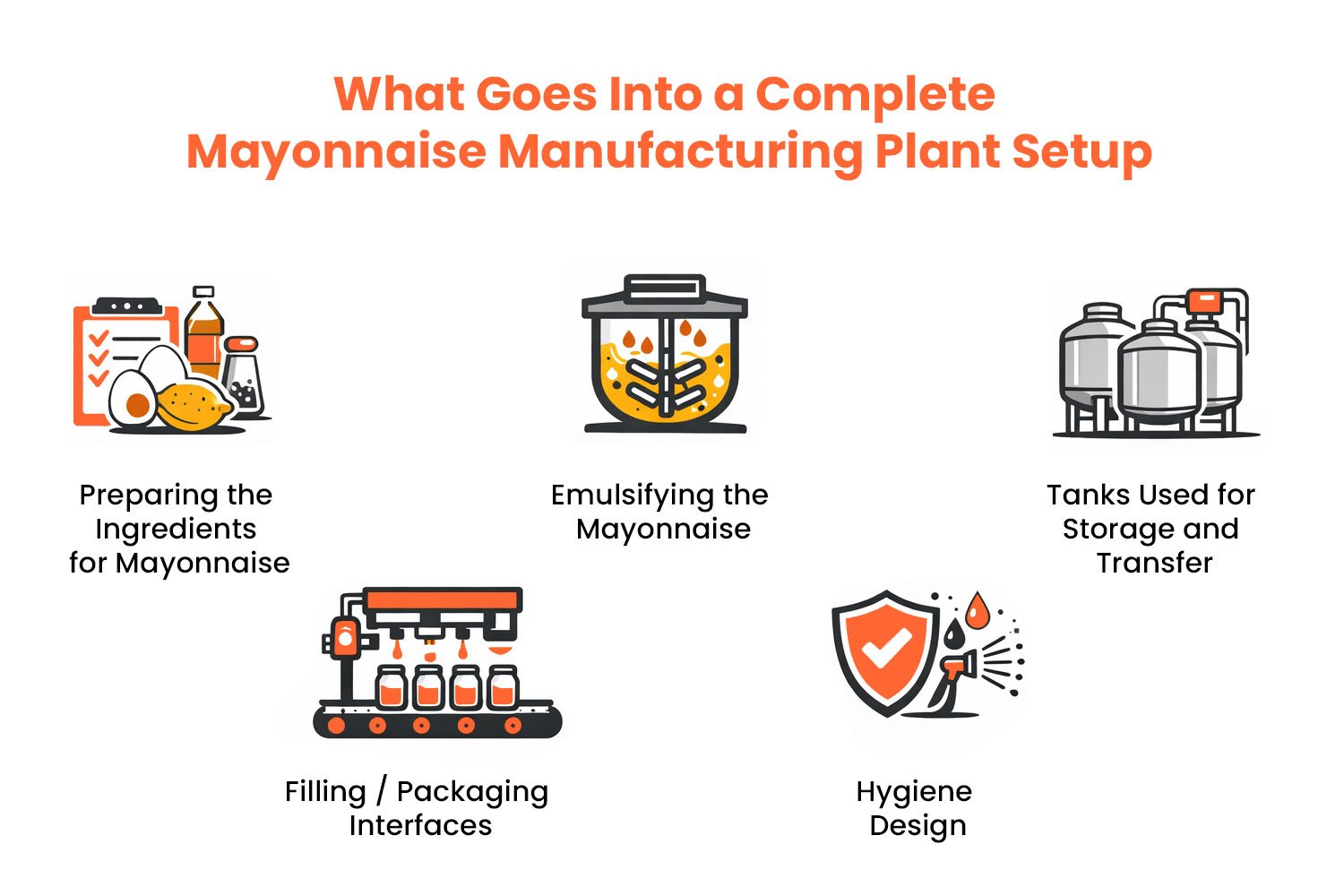

What Goes Into a Complete Mayonnaise Manufacturing Plant Setup

- Planning & Preparing the Ingredients for Mayonnaise: The Mayonnaise production process begins by determining how much of each ingredient (oil, eggs, water, vinegar, and dry ingredients) will go into the mixture and measuring/controlling that amount correctly so that your Mayonnaise tastes the same from batch to batch and produces stable Mayonnaise batches.

- Emulsifying the Mayonnaise: An emulsifying mayonnaise making machine is an essential piece of equipment for the mayonnaise production facility. The equipment will blend all ingredients with equal amounts of oil throughout the emulsifying mixture.

- Tanks Used for Storage and Transfer: After the emulsification process, the emulsified product moves to the holding tanks, where rest periods may occur before the product is either transferred to a batch or to a continuous production system for final processing. The holding tanks act as an area for staged products to rest before being shipped to a customer, retail store, etc.

- Filling / Packaging Interfaces: Modern packaging facilities allow for a more efficient transfer of product from production to the filling and packaging machine. With proper design and operation of the transfer operation, there should be no product loss, contamination, or waste.

- Hygiene Design: Most new production facilities have been designed with an emphasis on sanitary design and incorporate an efficient cleaning-in-place system. They also incorporate cleaning features that allow employees easy access to cleaning products and tools while remaining compliant with the applicable food safety laws and regulations.

Conclusion

We at Foodsure Machines create mayonnaise plants that are functional. Our priorities are growth, consistency, and efficiency. Our equipment, assistance, and knowledge enable your company without any problems in the future.

FAQ

What does a mayonnaise plant factory mean?

It is a location where machines and systems are installed in order to transform raw materials into standardized quantities of mayonnaise.

How much would a mayonnaise plant cost in India?

It is conditional on its size and level of automation. You are typically spending between 8 lakh and 75 lakh rupees.

What is the capacity of a small mayonnaise plant?

The small plants normally yield between 200 and 500 kilograms per day. Something to begin with, without straining your budget.

Should a mayonnaise plant be approved by FSSAI?

Yes. Any food production facility must comply with the regulations of FSSAI in order to be licensed legally.

What is the difference between semi-automatic and fully automatic plants?

Plants that are semi-automatic require some labor. Most of the steps are automated in fully automatic plants.

Is it possible to have sauces created by another plant?

Yes. When it is made in such a way that it can be mixed and cleaned easily, then you can change the products that you are using without much difficulty.

The time taken to install a mayonnaise plant is how long?

Usually one to three weeks. Larger or more elaborate installations may require a bit more time.

Do they offer operator training by manufacturers?

Yes. They ensure that your employees are acquainted with the operations of operating the plant effectively at the outset.

Is it possible to increase the production later?

Numerous facilities are constructed to expand your company. It is possible to increase the capacity or automation without the need for a new system.

What is the nature of the stainless steel used?

Mostly SS 304 or SS 316. They are both food safe and resistant to corrosion.

How The space will I require to put a small plant is how much?

It is typically enough to cover about 300 to 500 square feet. Those will consist of tanks, mixers, and space to move.

Do they have after-sales services from the manufacturers?

Yes. They ensure that the plant is maintained, supply spare parts, and give guidance to ensure the plant is operating well.