Were you aware that more than 60% of mayonnaise first-time batch trials end in failure during commissioning, not due to the recipe but as a result of a defective setup?

Small manufacturers make the most costly mistakes between delivery and the first production batch. What happens when your oil separates, the texture collapses, or the raw material is wasted even before production gets stabilised?

This mayonnaise machine setup guide details the exact step-by-step setup operation, which is a great way to avoid weeks of trial and error, to keep your yield safe, and to be able to start production from day one.

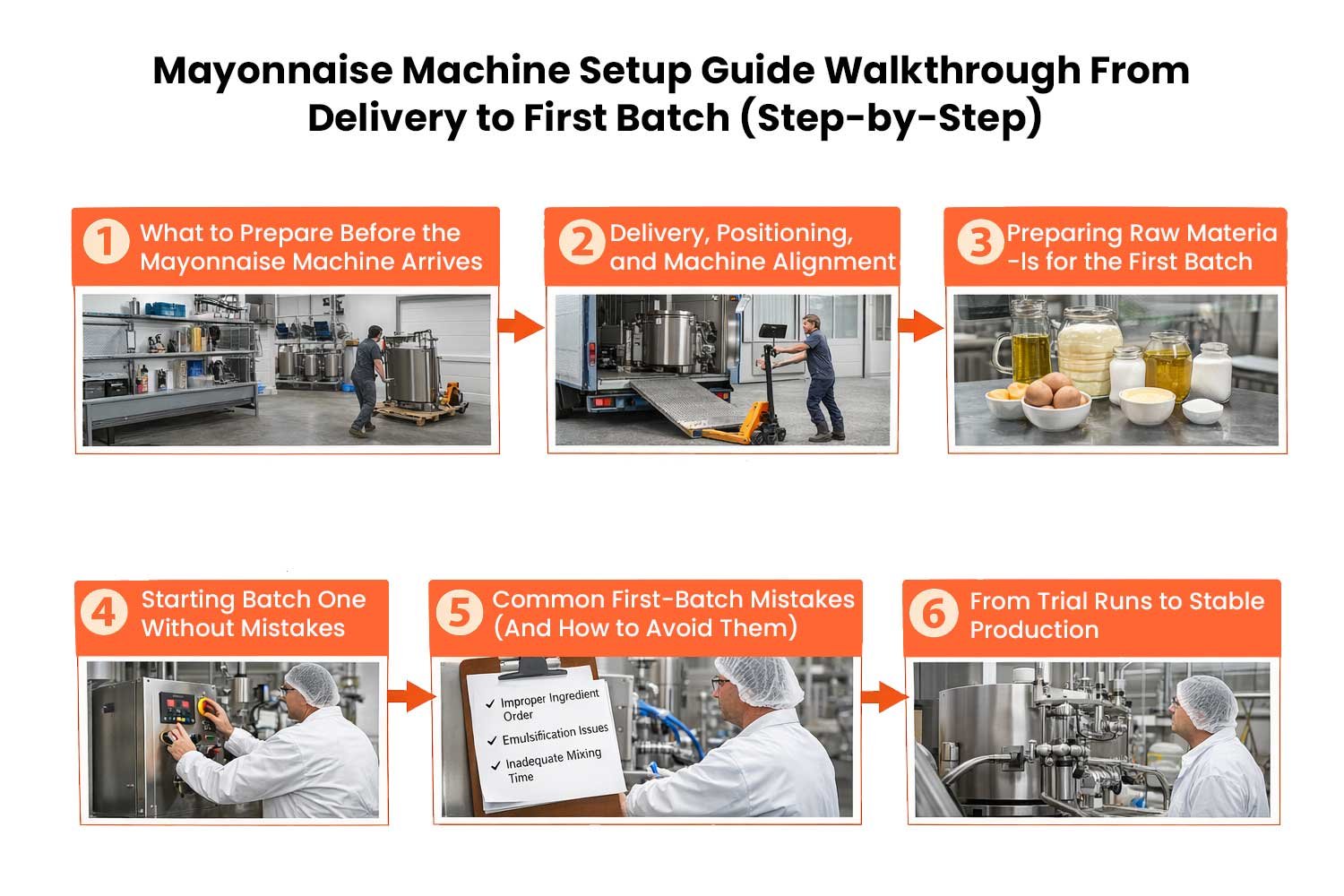

Step 1: What to Prepare Before the Mayonnaise Machine Arrives

The truck delivery should not hold up the start of the factory work, as an appropriate mayonnaise making machine setup goes even further back.

Make sure your place of installation is suitable

- The floor must be flat and level with appropriate drainage.

- Enough space for operator movement and cleaning.

- Controlled airflow with clear separation between the raw material and finished product zones.

Preparation of utilities

- Power supply must be stable and correspond to the machine specifications.

- The water line should be very clean, both for the water phase and CIP.

- Compressed air supply, if required by the system.

- If you decide to skip these basics, you will often find that there are delays on installation day.

Step 2: Delivery, Positioning, and Machine Alignment

A mayonnaise production line must be delivered and positioned properly if the emulsification is to be kept consistent and the uniform shear. Use laser tools to level it accurately to 0.5mm to prevent vibration-related oil separation.

Key Installation Steps:

- Levelling: Employ spirit levels; supports that are not level may result in 10- 15% batch variability.

- Inspections: Examine clamps, O-rings, and joints for leaks.

- Testing: When the machine is without a load, verify the wiring, sensors, and E-stops.

Step 3: Preparing Raw Materials for the First Batch

One of the main reasons people fail in their attempt to make mayonnaise from their first batch is the improper mixing of the ingredients, and this failure is always related to poor emulsification as a result of the temperature mismatch between the ingredients or undissolved ingredients that have been forgotten.

Major Preparation Steps:

- Oil Phase: A temperature between 20 – 25 °C is definitely the best one to get the most comfortable consistency. Try to use good, quality oils (e.g., soybean) with <0.1 % free fatty acids to be able to have stable droplet formation and avoid creaming.

- Water Phase: Emulsifiers (e.g., egg yolk at 10- 12%) and stabilisers (xanthan at 0.2, 0.5%) must be completely dissolved at 40 – 50 °C. The mixture should be passed through a 50-micron filter to remove the particles that cause shear instability.

By adjusting the temperature and pre-filtering, the success of the emulsion is more than 95% with a smooth and stable texture, and the separation of phases is significantly less likely.

Step 4: Starting Batch One Without Mistakes: The Correct Production Flow

Correctly running the very first batch is what basically defines baseline emulsion stability in mayonnaise making. It is a layer of sequence errors that causes 70% of initial failures due to droplet coalescence.

Key Execution Steps:

- Loading Sequence: Water phase (emulsifiers pre-dissolved) should be placed in the tank first; gentle agitation (400- 800 RPM) to form a vortex should be started, then oil should be added in 1- 2% increments every 30- 60 secs for progressive inversion emulsification.

- Parameters: Target 2500- 4500 RPM high, shear phase (shear rate 10,000–20,000 s⁻¹ ), total cycle 18- 25 min, keep < 42 °C by jacket cooling to avoid yolk coagulation.

Step 5: Common First-Batch Mistakes (And How to Avoid Them)

Typical errors in mayonnaise first, batch production are basically influenced by a hurried emulsification and thus result in a separation of the batch and in a non-uniform shear, accounting for 60–80% of failed trials.

- Oil Addition Overload: During 2000, 4000 RPM, add oil at 0.5 – 1 kg/min max (not >5% batch volume at once) to prevent droplet coalescence >10 microns, which is the main cause of phase inversion failure.

- Temperature Neglect: Keep the temperature < 40 °C with the help of cooling jackets; the excess heat (> 50 °C) causes the denaturation of the egg proteins and consequently a 30% drop of stability; if the temperature is rising >2 °C/min, take a break.

- Mid-Batch Tweaks: After validation, the RPM/shear/time should be fixed; changes interfere with zeta potential, giving variable viscosity (e.g., 5,000 – 100,000 cP swings).

Practice less than 5% failure rate, which can be scaled up to FSSC-compliant runs.

Step 6: From Trial Runs to Stable Production

To move from trial runs to stable production of mayonnaise, 2 – 3 validated batches are required to lock parameters, thus ensuring less than 2% variability for scalability.

Scaling Pointers:

- Trial Batches: Conduct 2 – 3 runs at 50 – 100% capacity, note RPM (3000 – 4500), temperature (< 42 °C), oil feed rate (1 – 2%/min), and viscosity (20k – 60k cP) to have a baseline.

- SOP Creation: Define the steps, cleaning (CIP 80°C), and QC checks (pH 3.8- 4.2, no free oil) in a one-page procedure that is in line with FSSC 22000.

- Operator Training: 4 hours practical: loading, monitoring, shutdown; certification through simulated faults.

Locked setups deliver consistent output, thereby allowing 500- 2000 kg/shift with no splits.

Self-Check: Is Your Mayonnaise Machine Properly Set Up?

Self-check ensures mayonnaise production equipment readiness and identifies setup defects that are fixed before commercial runs, thus saving 20- 30% of batch losses.

Deep Checklist Pointers:

- Levelling: Check <0.2mm difference with laser level; vibration <2mm/s to avoid shear drift.

- Sequence Doc: Confirm water, first, gradual oil SOP with exact times for consistency.

- Emulsion Proof: The very first batch keeps the 48h stability test (no separation, viscosity 25k-50k cP).

- Operator Mastery: Quiz on loading/RPM/emergency, 100% pass rate.

- CIP Clarity: Record 15 min alkaline/acid cycles at 70- 85 °C for hygiene.

Conclusion

We at Foodsure Machines are committed to guiding mayonnaise manufacturing businesses in properly setting up their automatic mayonnaise making machine from the very first day. Our mayonnaise machine setup guide not only cuts down on the losses due to trials but also makes the initial batches stable and helps in gaining trust. If setting up is a crucial factor, then our expertise is at work directly on your production line and not merely in reports.

Frequently Asked Questions – Mayonnaise Machine Setup

What is a mayonnaise machine setup guide?

It’s a practical guide that explains how to install the machine, set the correct parameters, and run the first batch properly so the emulsion remains stable from day one.

How long does the mayonnaise machine setup take?

Most setups take 1–2 days if utilities, flooring, and operators are prepared in advance.

What should be ready before machine installation?

Stable power, clean water lines, a level floor, proper drainage, and the operator who will run the machine.

Why does mayonnaise separate during the first batch?

Oil is often added too quickly, or emulsification parameters (RPM, temperature, shear rate) are incorrect during the initial sequence.

Is operator training required during setup?

Yes — even a well-designed machine fails without trained operators who understand loading sequence, RPM control, and emergency procedures.

What is the correct loading sequence?

Start with the water phase (emulsifiers pre-dissolved), begin gentle agitation, then add oil slowly in controlled increments.

Can small units achieve commercial consistency?

Yes — as long as shear control is correct and batch parameters are documented and followed consistently.

What temperature is ideal during emulsification?

Keep the mix controlled and below heat-stress levels so protein structure and emulsion stability are not weakened.

How many trial batches are needed?

Two to three controlled trial batches are normally required to lock parameters and stabilise production.

What causes an unstable mayonnaise texture?

Over-shearing, poorly hydrated stabilisers, temperature mismatch, or rushing the batch sequence.

Is CIP required during initial setup?

Yes — hygiene validation and CIP cycles are part of commissioning, not an afterthought.

When is the setup considered complete?

When the first batch runs stable, the result is repeatable, and production parameters remain consistent across validated runs.