At Foodsure Machines, we are indulged with a mid-scale Indian food manufacturer producing packaged mayonnaise and sandwich spreads. The client was operating a 300 L batch mayonnaise making machine and supplying regional distributors, with monthly output capped by yield loss and batch inconsistency. This mayonnaise machine case study shows, with real plant data, how the right 500 L mayonnaise machine corrected yield losses and stabilised large-batch emulsification.

The Production Challenge We Observed

When the client came to us, it was clear that they had these 3 problems:

- 7-10% loss of raw material per batch due to unstable emulsification.

- Oil separation occurred frequently during peak production days.

- Scalability was constrained without additional labour or floor space.

Their goal was straightforward: To raise the volume of output that is actually usable by at least 25-30% without an increase in batch failures.

This mayonnaise machine case study highlights the real-world challenges mid-scale manufacturers face when small-batch systems can’t meet demand.

Baseline Performance (Before Upgrade)

| Parameter | Existing System |

|---|---|

| Machine Capacity | 300 L batch |

| Average Yield | 88–90% |

| Raw Material Loss | 7–10% |

| Mixing + Cleaning Time | 45–50 minutes |

| Batches per 8-hour shift | 8 |

| Daily Sellable Output | 2,100–2,200 L |

| Monthly Output | 42,000 L |

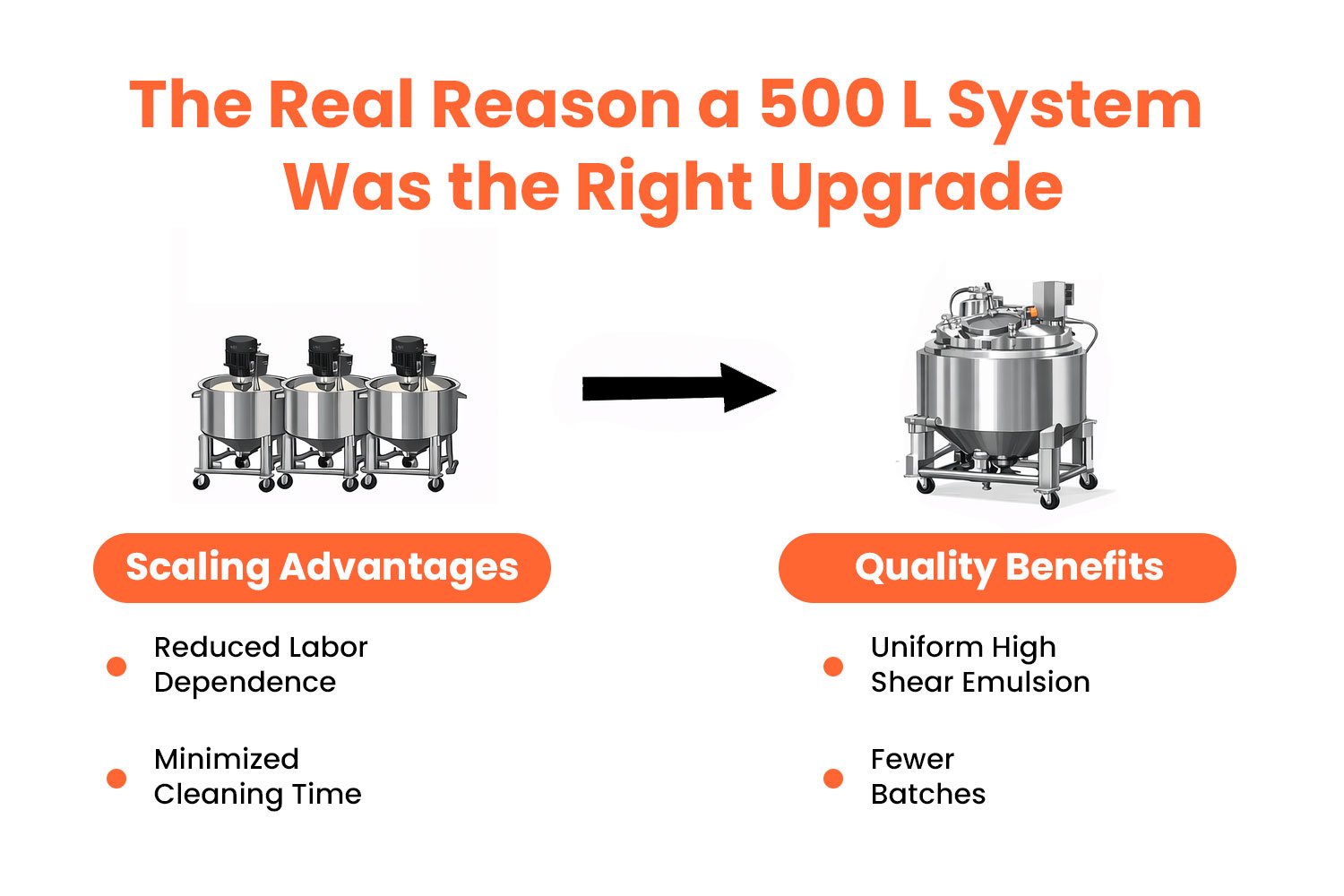

The Real Reason a 500 L System Was the Right Upgrade

Upgrading to a single 500L Mayonnaise Machine simply restructures your mayonnaise production line by eliminating small parallel mixers, which reduces the inefficiencies of labor, cleaning, and batch variability.

Scaling Advantages

- Reduced Labor Dependence: The operator involvement of a single unit is lowered by 50- 60% as the shear and mixing are automated for a hands-off, consistent result as compared to manual small-batch supervision.

- Minimized Cleaning Time: Shorter CIP (15-20 min) as compared to several units can reduce the total downtime by 40%, and throughput can be increased to 500 kg/hr.

Quality Benefits

- Uniform High – Shear Emulsion: Keeps droplet sizes less than 5 microns throughout the entire volume, 98%+ yield, and repeatable quality are ensured.

- Fewer Batches: The machine makes the turnaround 2 – 3 times faster, thus less variation is present, and scalability is improved for a consistent supply to the market.

A Closer Look at the 500 L Mayonnaise Machine

The 500L Mayonnaise Machine is an industrial mayonnaise machine designed to produce high yield, consistent results using the most advanced engineering and high shear emulsification technology.

Core Features for Yield

- The rotor-stator design has been optimised for emulsifying thick, high oil content water/oil emulsions (up to 70% oil content). The machine produces stable emulsions with droplet size <5 µm, with an average yield of at least 98%.

- The mayonnaise production equipment has a variable speed range (500 – 5000 RPM) for reproducibility and a 2–3% reduction in batch-to-batch variability.

Core Features for Consistency Enhancement

- New internal geometry, including curved baffles, eliminates virtually all dead zones in the machine and creates uniform flow, yielding less than 1% waste.

- The machine has a fast cleaning cycle (automated Clean-In-Place (CIP) 15-20 minutes) that results in 40% less cleaning time and uses SS304 for cleanability and to avoid product residue on machines.

What Changed After Installation

| Parameter | After 500 L Machine |

|---|---|

| Batch Volume | 500 L |

| Average Yield | 96–97% |

| Raw Material Loss | 3–4% |

| Oil Separation / Breakage | Negligible |

| Mixing + Cleaning Time | 35–40 min |

| Effective Cycle Time per Batch | 45 min |

| Batches per 8-hour Shift | 10 |

| Daily Sellable Output | 4,800 L |

| Monthly Output (20 days) | 96,000 L |

| Batch-to-Batch Consistency | High (minimal viscosity variation) |

| Rejection / Rework Rate | <1% |

| Labour Required per Shift | 1 operator |

| Cleaning Method | Integrated CIP |

| Water Used per CIP Cycle | Reduced vs 300 L system |

| Downtime Between Batches | Minimal |

| Energy Efficiency | Improved per litre produced |

| Cost per Litre (Processing) | Lower than the previous setup |

| Scalability | Ready for higher shift utilization |

This section of the mayonnaise machine case study shows measurable gains in yield, efficiency, and batch consistency.

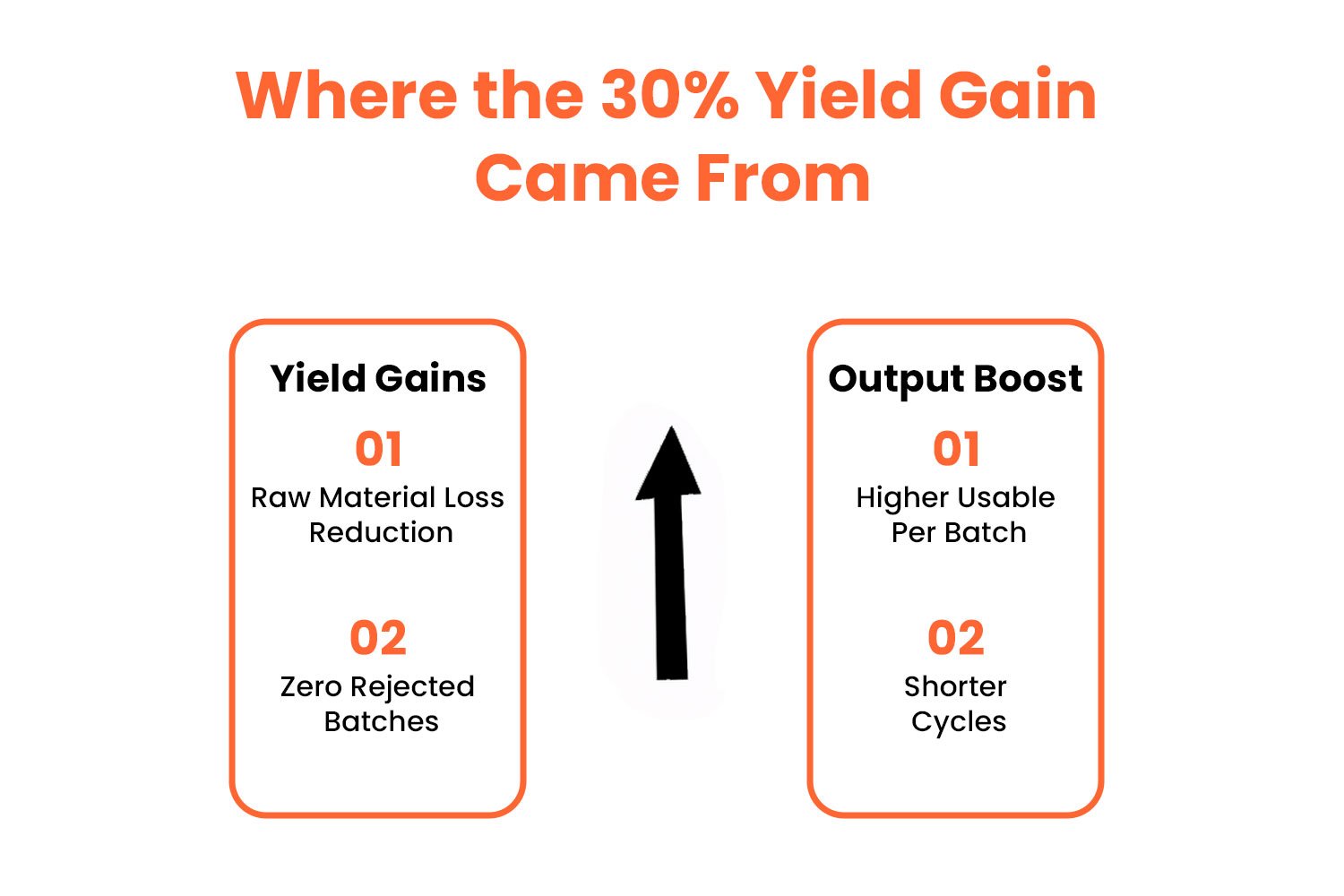

Where the 30% Yield Gain Came From

The first significant change came from a direct attack on the losses and inefficiencies in the process. As a result, the 500L Mayonnaise Machine has an effective usable output by 30% from 270L usable (300L batch) to 480L usable (500L batch).

Yield Gains

- Raw Material Loss Reduction: Perfectly controlled high shear emulsification and dead zone-free geometry helped to lower the losses by 5- 6%, thus more oil and water emulsion was retained.

- Zero Rejected Batches: Stable droplet size (<5 microns) through variable RPM helps oil separation to be avoided, thus the previous waste of 10- 15% has been largely eliminated.

Output Boost

- Higher Usable Per Batch: 96% yield (480L) against 90%, thanks to uniform mixing.

- Shorter Cycles: Processing time is 20- 25% shorter, plus CIP allows 20% more batches/shift, the monthly output has been increased by 30-35% without the need for extra staff.

How These Results Compare to Industry Benchmarks

- Batch process efficiency: Generally, a batch facility for mayo of around 800 kg/day will be able to operate in 8 hours at a large scale. Thus, this shows that the capacity for small-scale is quite high.

- Mixing quality influence: To a great extent, high shear mixing technology can decrease the production costs and the consumption of raw materials by 20, 40% per kg of product, as a result of better emulsification and fewer rejects.

The manufacturer’s performance after the upgrade is now operating at a higher level of efficiency when compared to typical smaller machines.

Key Points

- The right capacity isn’t just about size; it’s about emulsion control and waste.

- Value added through a high-shear mixing machine continues from batch volume and increases the yield and quality performance.

- Benchmarking against popular techniques (industry loss ranges, batch capacity norms) enhances claims.

Have a Question? Let’s Connect 🤝

Instant support for machines, production & process optimization.

Conclusion

At Foodsure Machines, we concentrate on throughput and not just machine size. This is a mayonnaise machine case study in point to demonstrate what the right 500 L system can accomplish: winning losses back, stabilising quality, and scaling output profitably. Our methodology stands on the ground of process knowledge and pragmatic machine which translates into measurable success.

Frequently Asked Questions – Mayonnaise Efficiency Improvement

What does mayonnaise efficiency improvement actually mean?

It is not just about bigger machines. It means producing more usable mayonnaise from the same batch while wasting less oil, egg, and water.

How did this case study improve efficiency?

By replacing a 300 L batch system with a 500 L high-shear machine, batch stability improved and usable output increased by nearly 30%.

Why is yield such a big deal for efficiency?

Every liter lost due to separation or poor mixing directly reduces profit. Higher yield means better efficiency and lower cost per liter.

What was causing inefficiency before the upgrade?

Unstable emulsions, frequent oil separation, and inconsistent batches. Individually small issues, but together they caused major losses.

Does faster mixing actually help?

Yes. Faster cycles allow more batches per shift, reduce downtime, and minimize operator-related errors.

Can efficiency improve without extra labor?

Absolutely. High-shear systems operate largely hands-off, allowing one operator to manage work that previously required multiple people.

How does raw material loss affect efficiency?

Lower raw material loss increases effective output. Reducing waste from 7–10% to 3–4% delivers a major efficiency boost.

Is consistency as important as capacity?

Yes. Larger capacity means little if batches vary. Consistent droplet size prevents oil separation and ensures uniform quality.

How does cleaning influence efficiency?

Integrated, faster cleaning reduces downtime between batches, allowing more productive hours per shift.

Do small adjustments really matter?

Yes. Adjusting RPM, internal geometry, and shear control can improve yield and reduce waste without expanding floor space.

Which products benefit from this approach?

Mayonnaise, sauces, dressings, and any oil-water emulsion prone to separation benefit from controlled high-shear processing.

What’s the main takeaway?

Efficiency is not just about bigger equipment. It comes from process understanding, controlled emulsification, reduced waste, and smarter batch execution.