Rajkot has never been known for makhana, but now the Makhana Processing Machine in Rajkot makes flavoured snacks that people all over India buy. Local processors switched from trading raw materials to making goods with extra value by using machines for grading, roasting, and flavouring. That change led to consistency, better profits, and strong demand from stores. Rajkot demonstrated that you don’t have to be in Bihar to run a successful makhana business India. All you need are the right tools and a smart plan for how to run it.

Rajkot Made It Work with Small Scale Food Processing Machines

There was no tradition of makhana here, no head start, but that didn’t matter. They saw a chance and didn’t wait around. No hype, no over-planning, just clear steps that made sense. The idea wasn’t to look big. What this really proves is that good decisions matter more than having a huge budget. Rajkot’s success came from executing quick moves and products that could hold their own on retail shelves.

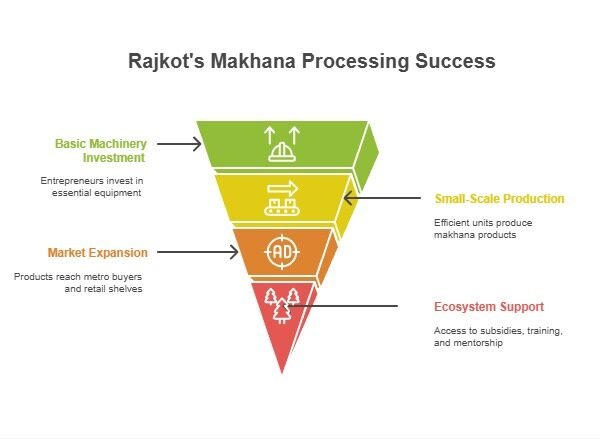

Availability of Skilled Agriculture Entrepreneurs

- After COVID, a lot of farmers and agri-entrepreneurs shifted into affordable fox nut processing machine in Rajkot instead of selling raw produce.

- Their experience farming helped them understand raw material quality, which cut down on waste and raised returns.

- Makhana market was expected to grow from ₹8.5 billion to ₹19.6 billion, so makhana business India owners saw a clear demand opportunity and acted early.

Adoption of Small-Scale Food Processing Machinery

- Compact equipment for sorting, roasting, and flavouring led to growth, not huge factories.

- These small-scale makhana machines run on low power, need fewer workers, and are easy to operate.

- First-time processors were able to launch multiple flavour SKUs and serve metro buyers because the output was consistent.

- Businesses could grow without taking big loans or taking on risks when the cost of machinery went down.

Support from the Local Ecosystem

- Small businesses and the government helped processors by giving them loans and other resources.

- Non-governmental organisations(NGOs) and training centres helped new business owners learn how to use machine operations and food processing basics.

- Local machine suppliers assisted with installation, trials, and troubleshooting, lowering the fear of starting.

- Rajkot’s environment made it possible for other districts to use it as a model for affordable fox nut processing machine in Rajkot.

Makhana Processing Machine Cost in Rajkot and Profit Potential

The main point that entrepreneurs focus on centres around two factors that determine their potential income from their investment.

Estimated Machine Cost for a Small Setup

| Machine | Purpose | Approx Price (₹) |

|---|---|---|

| Grading Machine | Size sorting and cleaning | 1.2 – 2.5 lakh |

| Roasting Machine | Puffing and roasting | 2 – 5 lakh |

| Flavoring Machine | Seasoning and coating | 1.5 – 3 lakh |

| Packaging Machine | Pouch filling and sealing | 2 – 4 lakh |

Total setup investment

A small-scale makhana processing unit in Rajkot can start around ₹2.5 lakh and go up to ₹15 lakh, depending on automation and capacity.

Simple Monthly Profit Example:

- The small unit processes 1,000 kg of makhana every month.

- Extra revenue from value addition results in a monthly income of ₹1,20,000.

Estimated Monthly Operating Costs

- Labour costs range from ₹40,000 to ₹60,000.

- Power and fuel costs range from ₹15,000 to ₹25,000.

- Packaging materials costs range from ₹20,000 to ₹30,000.

- Miscellaneous expenses cost between ₹10,000 and ₹15,000.

- The total monthly cost ranges from approximately ₹90,000 to ₹1,30,000.

What Happens When Small Scale Food Processing Machines Meet Local Action

Here’s the thing, Rajkot didn’t wait for a perfect blueprint. It just started. And the numbers now tell a sharp, undeniable story.

| Growth Metric | 2021 | 2025 | Change |

|---|---|---|---|

| Processed Makhana Volume | 120 metric tons | 480 metric tons | 300% increase |

| Active Processing Units | 8 units | 35 units | 4x more operators |

| Flavored Makhana SKUs | 2 variants (Classic, Spicy) | 7 variants (e.g., Masala, Cheese) | New product lines added |

| Annual Retail Pack Output | 15,000 packs | 110,000 packs | 7x increase in market-ready SKUs |

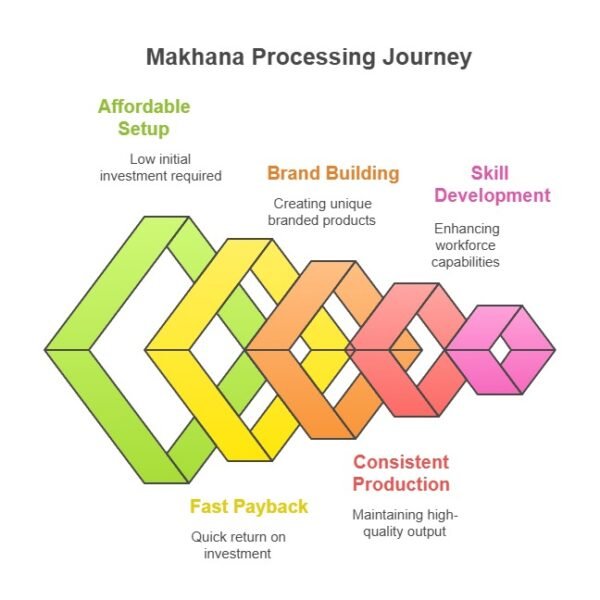

Rajkot Used Small Scale Food Processing Machines to Move Fast and Win

The entrepreneurs in Rajkot pursue business growth through their production operations, which they maintain at their current level. The entrepreneurs establish successful snack brands through their small-scale makhana machines, which produce snacks that customers buy from stores.

The makhana processing machine model succeeds across India because of its following attributes:

- The system requires a capital investment between ₹2.5 lakh and ₹15 lakh for its full operation, which includes sorting and heating, flavouring and packing processes.

- The system uses compact automation technology, which decreases both workforce requirements and operational expenditures for each day of business.

- The majority of units achieve financial returns within 12 to 18 months because they generate higher profits from their value-added makhana products.

From Raw Commodity to Branded Snacks

- The processors stopped selling raw makhana as a loose product.

- Machines create flavoured and roasted SKUs which are available for retail sale through retail-ready packaging.

- Branded makhana products generate significantly better profit margins compared to raw bulk products.

The system maintains constant production capabilities because it can handle increased production demands.

- The makhana processing machine in Rajkot produces consistent output because it delivers precise grading and complete roasting results.

- The system achieves quality standards for retailers and distributors because it produces consistent results between different production groups.

- The system enables testing of new flavours through simple SKU samples, which allow production to continue without interruptions.

From Zero to Shelf: Powered by Makhana Machines

Makhana processing machine in Rajkot aren’t scaling by chance. The shift came when compact, purpose-built machines hit the ground, simple to run, easy to maintain, and made for high food-grade standards. Now, let’s look at what’s powering this change:

-

Built for Small Spaces, Big Results

You don’t need a giant factory to get started with a makhana processing plant in Rajkot. A compact grading machine will sort your kernels by size and quality accurately, batch after batch. Roasting units can handle 50 to 100 kilos an hour, and the digital heat controls keep the roast even without burning.

-

Start Small, Grow Smart

The real advantage is modular automation. You can begin with just the basics: grading, roasting, and flavoring, and add on as you scale. Need packaging later? No problem. Want to tweak your flavor batches? Most makhana processing plant let you dial that in with easy digital controls. This approach keeps upfront costs low and lets production grow with demand.

-

Easy to Maintain, Built to Last

These small-scale makhana machine are made with stainless steel, so they are built to handle daily use and quick cleanup. Spare parts are easy to find. Basic maintenance doesn’t need a technician. Some systems even come with remote monitoring and simple interfaces, so you can spot issues early and stay on track without outside help.

Also Read: Top Makhana Machine Companies in India – See who’s manufacturing reliable grading, roasting, and flavoring units.

Foodsure Machines: The Backbone of Rajkot’s Makhana Growth

Foodsure Machines are playing a big role in the makhana processing machine in Rajkot. Our compact grading, roasting, flavoring, and packaging units are built for smaller operations but deliver consistent, retail-ready output. Everything’s food-grade, easy to run, and built to scale without chaos. That’s how rural entrepreneurs and local SMEs are turning raw makhana into sellable, branded snacks quickly, cleanly, and with enough quality to hold their own in modern retail. Want to set up your own makhana line like Rajkot? Talk to our machinery experts at Foodsure Machines. Fast setup. Smart ROI.→ Contact Us

FAQ

1. What is a makhana processing machine in Rajkot used for?

Through sorting, roasting, seasoning, and packing, it takes raw makhana and turns it into a snack.

2. How much does a makhana processing machine in Rajkot cost?

Depending on how much it can do and how automated it is, a small-scale setup usually costs between ₹2.5 lakh and ₹15 lakh.

3. Is Rajkot a good place to start a makhana processing business?

Yes, Local MSME help, easy access to machinery, and food entrepreneurs with a lot of experience make it easier to get started here than in most places.

4. Can small-scale machines handle commercial makhana production?

Yes, they can. A lot of small groups already give retailers and distributors high-quality goods.

5. What products can be made using a makhana processing machine?

You can make roasted, salted, masala, cheese, peri-peri, and other flavoured snack variants.