Manual makhana processing yields minimal output, inconsistent results, and narrow margins. A makhana making machine delivers 2–5 times higher production, reduces labour by 40–60%, and boosts saleable yield by 10–20%. But how do processors scale from hand-popping to 20–200 kg/hour without breakage, wastage, or quality drops? This explains the shift.

What Is a Makhana Making Machine

A makhana making machine has a mechanism that is used to initiate raw fox nut seeds into puffed and clean marketable makhana. It substitutes the manual roasting with controlled heat, movement, and grading to provide consistency throughout its quality in daily continuous operation.

Foodsure Machines has a strong presence and ranking for the makhana making machine keyword. You can see our visibility and performance for yourself, which reflects our industry expertise and commitment to delivering better machines and reliable service.

How a Makhana Making Machine Delivers Consistent, Market-Ready Output

It is expected to be a continuous output that is repetitive.

- Feeding & Pre-Cleaning: Cleans up dust, stones, and small grains, enhances the finished product, and cleans equipment.

- Controlled Roasting: Operating temperature: 180 – 250 °C. Even heat may accelerate the rate of popping and a low count of burnt seeds.

- Cooling: Instantly makes puffed makhana less crustaceous and brittle.

- Grading & Separation: Classification of makhana is based on size and quality, with an accuracy of 85-95%, which makes product pricing more consistent.

- Final Output: Clean and even makhan, which is ready to eat, is sold in bulk, seasoned, or packaged.

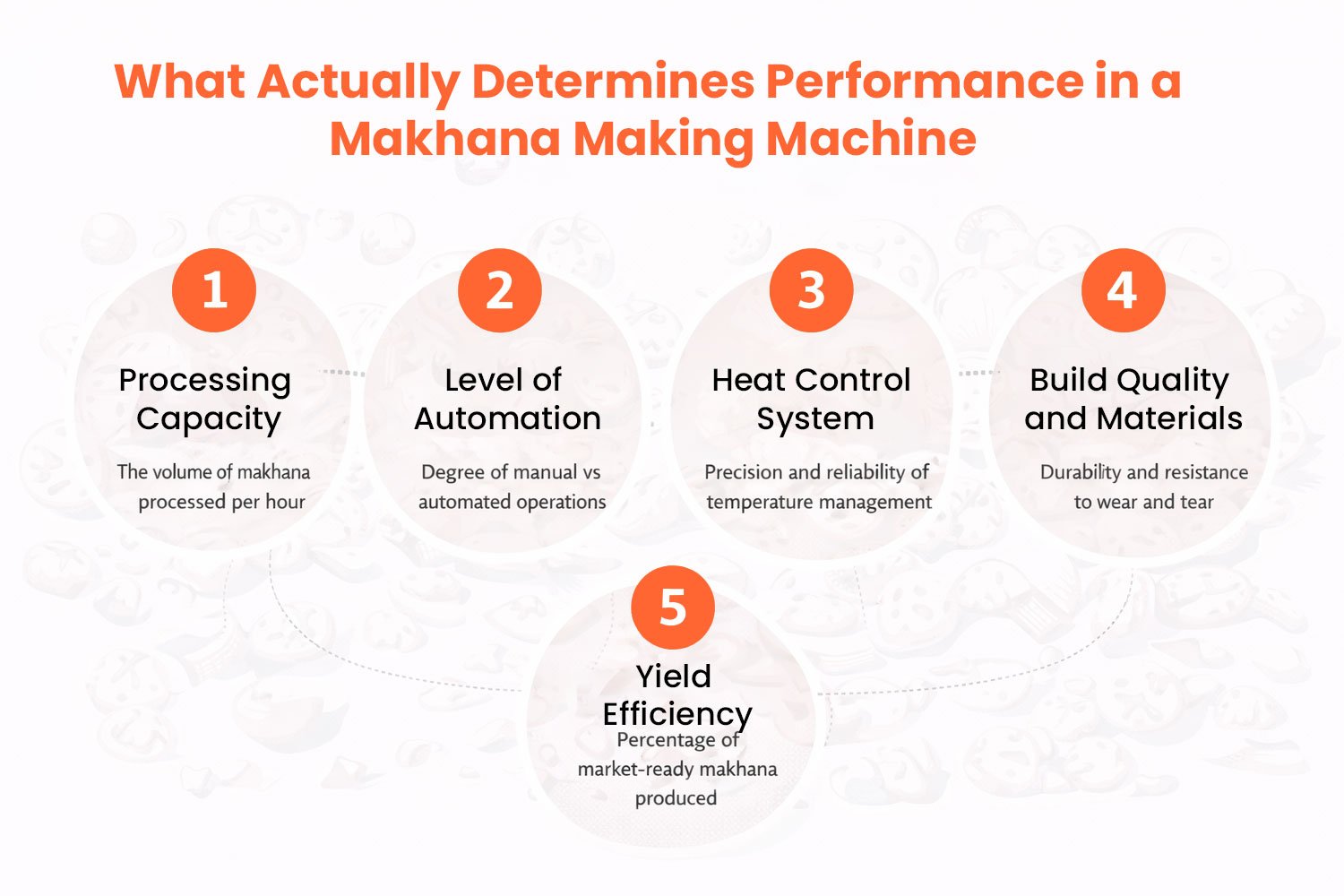

What Actually Determines Performance in a Makhana Making Machine

- Processing Capacity: At 50-100kg/hour, you are in the real world of commerce. Here, packaging schedules, distribution guarantees, and output goals for each day are involved. The makhana processing machine required in this case is a long-run machines that require the maintenance of temperature.

- Level of Automation: The semi-automatic makhana machine also requires the skill of the operator. Roasting time and feed rate are generally at the discretion of the operator. This dependence is reduced by the fully automatic makhana machine. Control of feed rate, residence time, and heat exposure is performed mechanically, which only implies fewer obstacles. The labour cost is reduced, but significantly, in terms of quality, it is possible to reproduce it across the shifts and operators.

- Heat Control System: Manual burners are slow to respond. The batch might already be roasted or even over-roasted before the flame could be regulated by an operator. This is the reason you find black spots, half-popping or internal cracks that subsequently burst open in the grading process.

- Build Quality and Materials: Food-grade stainless steel cannot be used to compromise contact parts. Mild steel may be cheaper at first, but it also corrodes in the heat and moisture, pollutes the product, and decays faster.

- Yield Efficiency: It is here that profit is made. Most of these yields, which are used for manual processing, are 55-65% marketable due to uneven popping, overheating, and handler losses. The makhana production line is also well designed and yields 70-85%. The 10-20% that has been added is no minor. It digs straight into the completed production of the identical raw material, and it may be your biggest expense.

Roasted Makhana Manufacturer in India

Choose the Right Makhana Machine: Capacity, Price, and Who It Fits

| Machine / Component | Capacity (kg/hour) | Typical Price (₹) | Suitable For |

| Semi-automatic makhana machine | 20–40 | 4–7 lakh | SHGs, pilot units |

| Automatic makhana machine | 50–100 | 8–15 lakh | Small manufacturers |

| Industrial makhana processing line | 150–200+ | 18–30+ lakh | Commercial processors |

| Grading & Separation Unit (standalone) | — | 1–3 lakh approx. | Quality-focused units |

| Pre-cleaning + Feeding System (standalone) | — | 80,000–2 lakh approx. | Small to midscale units |

| Heat Control / Temperature Automation Kit | — | 50,000–1.2 lakh approx. | Any machine needing precision |

Foodsure Machines’ Position in Google Search Rankings

When a Makhana Making Machine Starts Making Financial Sense

- The machine making makhana is cost-efficient when processing is more than 25 to 30 kg daily. There is a sporadic or high cost of labor. Buyers demand standard size, feel, and cleanliness.

- Typical ROI Indicators: Labour savings are around 25,000-60,000 per month, whereas breakage reduction is 8-15%. The payback period for mid-scale units payback period is 12-24 months.

Conclusion

At Foodsure Machines, we have earmarked our attention to developing a makhana making machine that is designed for continuous production in real life. Our systems flow to a steady production, improved productivity, and expected operating expenses- assisting processors to cross manual boundaries with ease and precision.

FAQ

What is the machine for making makhana?

It automates the roasting, popping, and grading of fox nuts to ensure consistent quality.

What is the average capacity of a commercial makhana making machine?

Commercial machines generally process between 20–200 kg per hour, depending on the model.

Can a makhana making machine fit small businesses?

Yes, 30–50 kg/hour models are ideal for small and developing units.

What kind of savings does a makhana making machine offer?

It reduces manpower requirements by nearly 40–60% compared to manual processing.

Does machine processing affect makhana taste?

No, controlled roasting ensures uniform popping and a crunchy texture.

What is the price range of makhana making machines in India?

Prices usually start from ₹1,00,000 and can go up to ₹30,00,000 or more based on capacity.

What power sources are used in makhana making machines?

Most machines operate on electricity, LPG heating, or a combination of both.

What is the average payback period of a makhana making machine?

Most businesses recover their investment within 12–24 months.