If you’re the operator of a small-scale makhana production unit, you’ve probably experienced the disappointment of burnt or under-roasted batches. This not only reduces yields, but it may negatively impact your reputation with customers. Here is some good news. Issues fixed by automatic makhana roaster technology are revolutionising the experience for FPOs and small manufacturers. In this blog, we’ll dive into why traditional roasting often fails, how automation ensures perfect batches every time, and the tangible benefits you can expect when you upgrade your roasting process.

Why Manual Roasting Fails and How Automatic Makhana Roaster Benefits Solve It

While small-scale manufacturers frequently employ roasting methods that are either manual or basic, these methods have several hidden problems that impact quality, yield, and profitability. The whole issue is as follows:

- Heated Unevenly Forces Product Loss: Traditional roasters often have hot spots or unequal distribution of heat. Some makhana will get burned while others remain under-roasted, resulting in mixed batches that cannot be sold.

- Processes that are Labour Dependent Multiply Errors: Manual tracking requires constant attention. Even the most experienced operators can sometimes err in timing or temperature, particularly when working on multiple batches, which typically results in roasts being either overdone or underdone.

- Growth Limitation due to Scaling Problems: Simply increasing the batch size in the manual roasters does not necessarily result in a large output. Larger batches will likely suffer more from uneven roasting and more wastage without getting the same production benefits.

- Energy inefficiency increases operating costs: Changing the temperature, rotating the pan, or adjusting the time of the batch frequently not only makes production slower, but it also requires more electricity or fuel. Increasing the operational costs per kilogram.

- Unseen Impact on the Profitability: The existence of these inefficiencies is silently consuming the profit margins. Waste, poor quality, and expensive labour and energy are the reasons that small manufacturers find it tough to go beyond 500-1000 kg monthly production without automation.

Takeaway: A small-scale manual roasting applies only to limited batches. A small-scale automatic makhana roaster machine is often the reliable option to upgrade for the purpose of ensuring consistent quality, reducing losses, and scaling production efficiently.

Issues Fixed by Automatic Makhana Roaster: Consistent Quality Every Batch

The issues fixed by automatic makhana roaster are particularly constructed to overcome these typical problems. They depend on precise temperature regulation, automated timing, and uniform heat distribution to make sure that every batch of makhana is roasted to perfection consistently.

Key Features That Prevent Burnt & Under-Roasted Makhana

- Precision Temperature Control: It ensures that every batch is roasted just right with precise temperature control.

- Automated Batch Timing: Operators don’t have to manually measure every single operation.

- Uniform Heat Distribution: Makhana are not burned due to extreme temperature.

- Adjustable Capacity: Suitable for small-scale units and can progress without sacrificing quality.

Real Results from Small & Medium-Scale Units

A farmer producer organisation (FPO) in Madhya Pradesh upgraded to an automatic roaster and cut wastage by 18% in the first month. Their monthly production increased from 800 kg to 1,200 kg without increasing the labour force. Complaints from customers regarding taste and quality went down to almost zero.

Why semi automatic makhana machines fail

How Upgrading to an Automatic Makhana Roaster Improves ROI and Productivity

Upgrading to Issues fixed by automatic makhana roaster gives benefits that can be measured:

- Reduced wastage: Every batch of roasted makhana is produced in a consistent manner, resulting in fewer ruined products.

- Energy saving: The optimised roasting cycles perfectly roast the makhana, which not only improves the quality of the CUPS because there are no burns or moisture, but it also saves electricity.

| Parameter | Traditional / Manual Roasting | Automatic Makhana Roaster | Business Impact |

|---|---|---|---|

| Monthly Output Capacity | 800–1,000 kg | 2,500–3,000 kg | 2–3× production without line overhaul |

| Wastage Due to Burnt / Under-Roasted Makhana | 12–20% | 2–4% | Direct raw material savings |

| Raw Material Loss (Monthly) | High (unrecoverable batches) | Minimal | Higher saleable yield |

| Labor Requirement | 2–3 operators per shift | 1 operator per shift | Lower manpower cost |

| Labour Cost (Monthly) | High & variable | Stable & predictable | Easier cost control |

| Energy Consumption per kg | High due to re-roasting & adjustments | Optimized & consistent | Reduced electricity / fuel bills |

| Machine Downtime | Frequent (manual dependency) | Low (automated cycles) | Better production planning |

| Quality Consistency | Batch-to-batch variation | Uniform for every batch | Better brand reputation |

| Maintenance Cost | Low but frequent issues | Planned, preventive maintenance | Fewer breakdown surprises |

| Scalability Cost | Requires more labour & supervision | Modular expansion possible | Scale without chaos |

| Estimated ROI Timeline | Not measurable | 10–16 months (avg.) | Faster payback on machine investment |

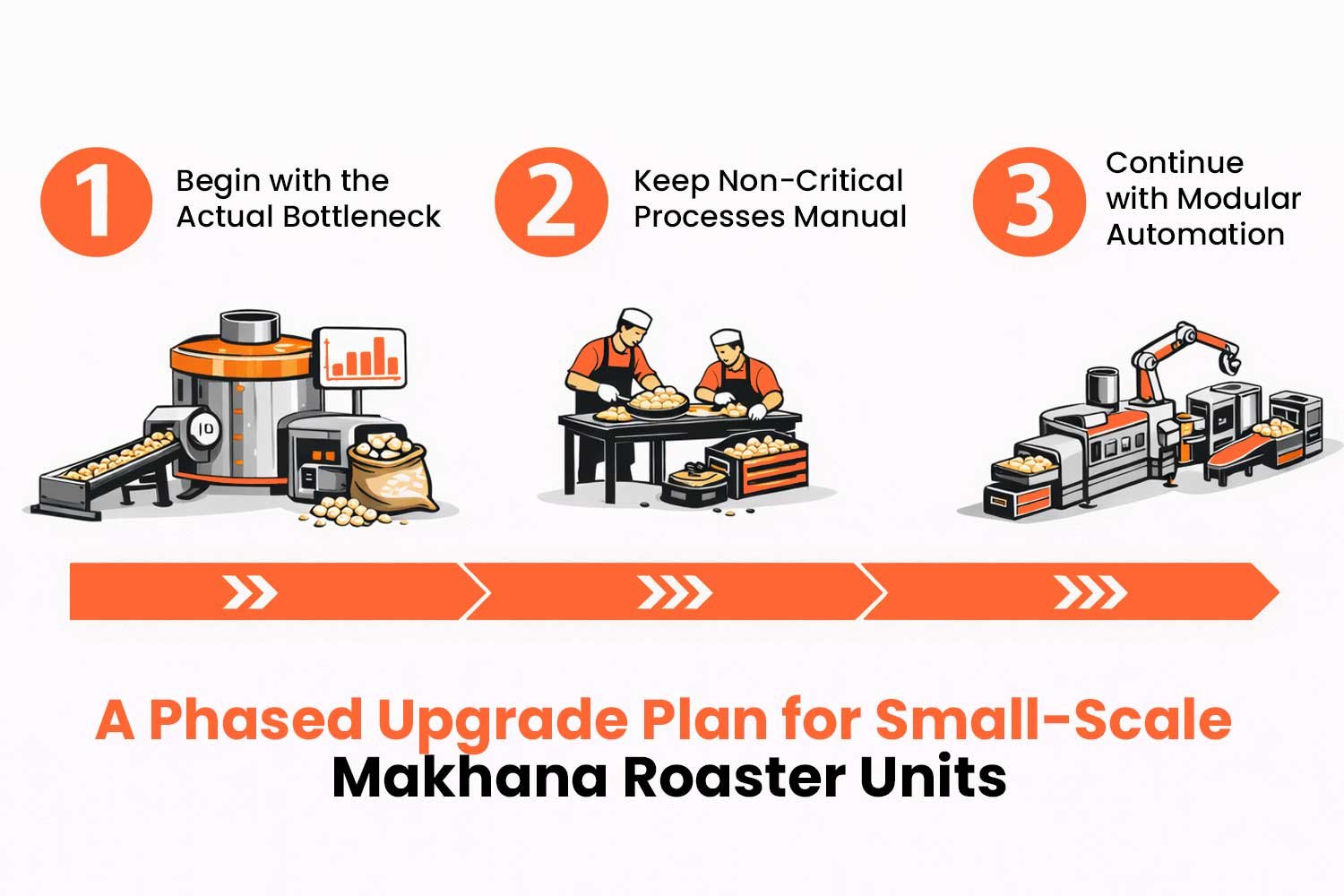

A Phased Upgrade Plan for Small-Scale Makhana Roaster Units

Smart manufacturers do not take the risk of automating the entire process all at once. They instead adopt a gradual enhancement plan that secures liquidity and, at the same time, minimises the risk of interruptions in production.

- Begin with the Actual Bottleneck: Identify the stage where quality breaks down. This often occurs during roasting, which in turn leads to maximum wastage due to either burning or under-roasting. Improvement of this point can result in output quality being raised instantly.

- Keep Non-Critical Processes Manual: The initial phase may involve some manual operations for purposes like cooling, seasoning, and packing, etc. This way, the company saves a considerable amount that would have been spent on acquiring new makhana making machines while at the same time making a positive contribution towards the consistency of the final product.

- Continue with Modular Automation: Once the demand rises steadily, consider adding automatic makhana roaster machines further down the line. This way, the makhana production line remains balanced, and the company benefits from clear ROI for every upgrade.

This gradual approach to automation ensures that every single rupee spent on automation yields not just higher capacity in theory but also measurable and long-term gains.

Conclusion

We at Foodsure Machines assist makhana producers in transitioning from erratic roasting to dependable, expandable production. Our automated makhana roasters are designed to reduce waste, enhance quality, and provide a tangible return on investment. We can assist you if you are prepared to scale wisely.

FAQ

What issues are fixed by an automatic makhana roaster?

It eliminates burnt batches, under-roasted kernels, uneven texture, excess wastage, and batch-to-batch output variation.

How does an automatic makhana roaster prevent burning?

The roaster maintains stable temperature and distributes heat evenly so no section overheats while another lags behind.

Can automatic makhana roasters reduce production wastage?

Yes. Consistent roasting cycles significantly reduce rejected or reworked batches.

Is an automatic makhana roaster suitable for small manufacturers?

Yes. Modular designs allow small units to automate critical stages first and scale gradually as demand grows.

How does an automatic makhana roaster improve ROI?

It lowers labour input, cuts energy waste, and increases saleable output from the same raw material.