Achieving pan-India distribution without sacrificing speed or quality requires upgrading your makhana production line. A well-designed industrial makhana processing line addresses many typical limitations, preparing your unit for large-scale operations. Here are the five most powerful upgrades that will help you streamline production, ensure market-ready batches, and scale your business efficiently nationwide.

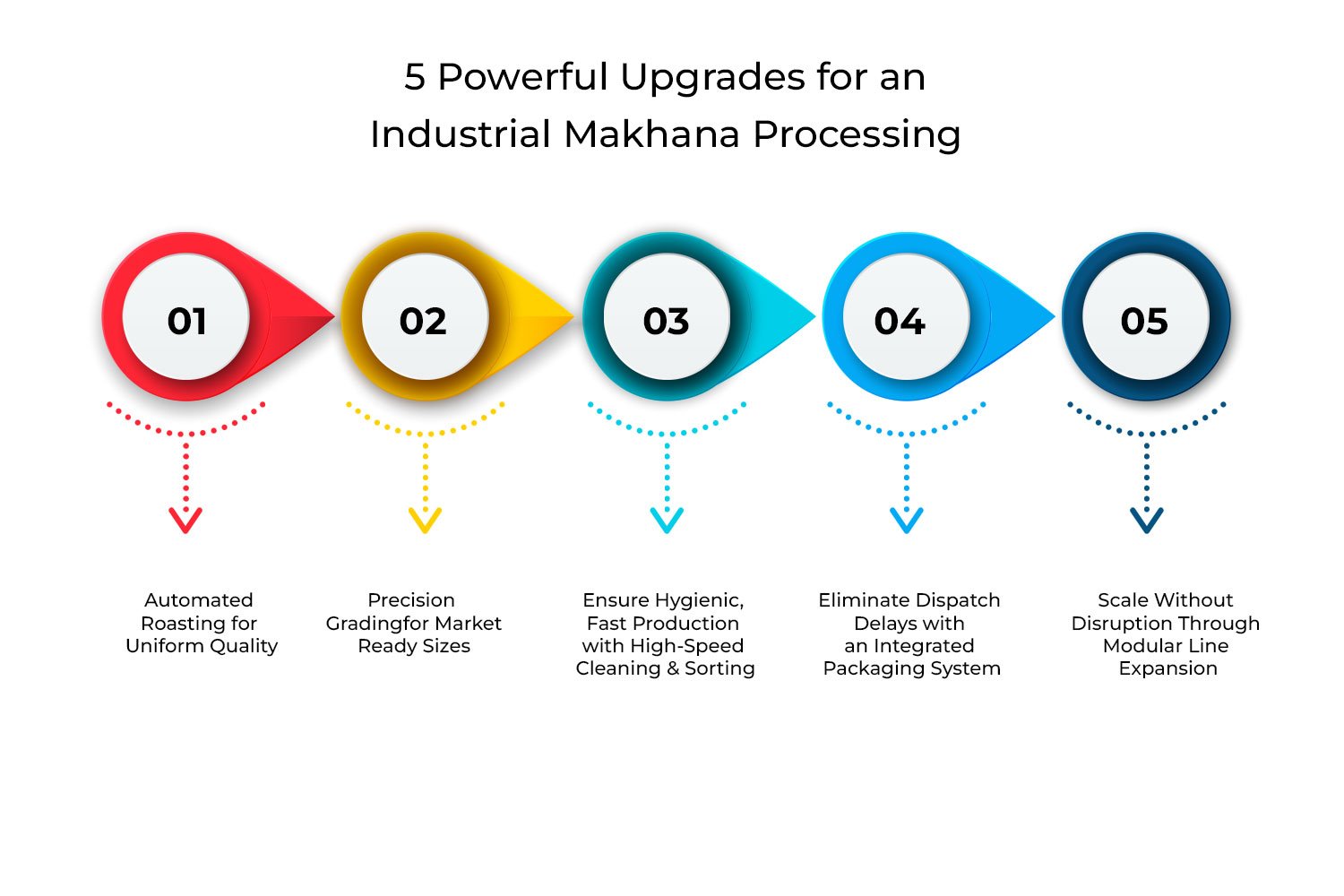

5 Powerful Upgrades for an Industrial Makhana Processing Line

A contemporary Industrial Makhana Processing Line signifies more than just larger machines. Additionally, the combination of automation, precision, and modular design eliminates production bottlenecks. The manufacturing process is supported by the automatic makhana roaster, which guarantees uniform quality for each batch, as well as the modular line expansion that permits gradual development. Every improvement is crucial in the areas of improving efficiency, reducing wastage, and seamless distribution throughout India.

1. Automated Roasting for Uniform Quality

An automatic makhana roaster will likely revolutionize your production since it guarantees that every lot is roasted uniformly, and the ideal colour, texture and taste are maintained.

Key benefits:

- Consistent quality across batches: The makhana roasting process is the same for all the kernels, resulting in the product having the same colour, texture, and crunch that the customers appreciate.

- With less manual monitoring required, the workers are available for other duties. The workers can concentrate on grading, packing, or quality checking while the roaster works independently.

- Quick production cycles enable us to meet demand nationwide. The roasting process is continuous and precise, resulting in higher output, and scaling up production becomes possible without sacrificing quality.

2. Precision Grading for Market-Ready Sizes

A precision makhana grading machine ensures that your makhana is sorted correctly by size and quality, and this way, each batch has the same quality and uniformity. This is important for producing market-ready makhana that meets the expectations of the retailers and consumers. These machines sort out small, broken, or low-grade kernels.

Main advantages:

- Uniform packing: Each pack appears very professional and uniform, thereby enhancing its visibility on the shelf.

- Improved brand image: Customers are always receiving high-quality and dependable goods.

- Increased profitability: Reduced waste leads directly to higher usable output and better margins because of the smaller number of defective kernels.

- Quicker processing: The automated makhana grading machine takes several hours less than manual sorting.

Choosing precision grading technology is a decision that instantly opens up your product for nationwide distribution.

3. Ensure Hygienic, Fast Production with High-Speed Cleaning & Sorting

A high-speed makhana sorter, working in conjunction with an industrial cleaning machine, can remove dust, stones, husks, and defective kernels in just a few seconds. The cleaned product is then suitable for roasting. These machines keep the hygiene standards, so that only the finest kernels are allowed to proceed in the production line.

Key benefits:

- Enhanced hygiene: The elimination of makhana with impurities leads to a product that is safer and cleaner.

- Reduced manual labour: Employees can do other jobs, which means that the company will have to pay less for labour.

- Faster production line: It quickly processes the big batches to satisfy the increasing demand.

- Consistent quality: Selection of only first-grade kernels ensures that every pack is of the same quality.

Investing in high-speed cleaning and sorting machines would be necessary if one wants to distribute the product all over India without compromising its quality.

4. Eliminate Dispatch Delays with an Integrated Packaging System

Makhana, a processed product, is packed in large quantities for the Indian market. Packaging performed by machines is efficient because it eliminates the possibility of spills and ensures a consistent weight. These automatic systems, designed for pan-India distribution, effectively address the previous delay issue since they include sealing, weighing, and labelling done in a single flow.

Major advantages are:

- Non-spill, clean packaging: Ensuring safe delivery through long-distance transport.

- Freshness for longer: Cool and crunch kept by airtight sealing.

- Quick dispatch cycles: Automation is fast enough for high-volume orders.

- Dispatched across the country: Packaging is done as per the requirements of both retail and logistics in India.

An integrated makhana packaging machine guarantees that your makhana is delivered to every market in top condition.

5. Scale Without Disruption Through Modular Line Expansion

Modular line expansion is a great approach for makhana processors as it allows them to increase the plant’s capacity without waiting for a full-scale setup. With the increase in demand, additional modules for roasting, grading, or packaging can be installed without disrupting the running operations. This method enables the smooth scaling up of the industrial makhana processing line, ensuring continuity of production even while capacity is being expanded. In contrast to rigid setups, modular systems can flexibly respond to market demands, seasonal fluctuations, and the growth of distribution.

Main advantages:

- Higher capacity without downtime: Install new makhana machines while production is ongoing.

- Lower investment risk: Sell more and then expand where necessary, step by step.

- Future-proof setup: Adapt the technology as your company grows.

- Operational flexibility: As per the specification, increase the capacity of various sections of the line.

Modular expansion will provide a greater degree of process control, reduce the time required for market acceptance, and give you confidence that expansion aligns with market demand.

How Smart Automation Makes Makhana Ready for Pan-India Distribution

The combination of these upgrades creates a fragmented setup that is transformed into a trustworthy and scalable system. A properly designed Industrial Makhana Processing Line enhances the three basics of nationwide distribution, speed, consistency, and control. The quicker production allows for the timely delivery of large orders, whereas the quality maintained throughout the process strengthens the relationship with distributors and retail chains. Automation throughout roasting, grading, cleaning, and packaging eliminates slowdowns and reduces waste resources, but also directly benefits margins and operational efficiency.

ROI Impact of Upgrade

| Upgrade Area | Operational Impact | Distribution Benefit |

|---|---|---|

| Automated Roasting | Uniform roasting, lower errors | Consistent product quality nationwide |

| Precision Grading | Size & quality uniformity | Professional packaging, fewer rejections |

| High-Speed Cleaning & Sorting | Faster, hygienic processing | Compliance with food safety standards |

| Integrated Packaging | Spill-free, sealed packs | Longer shelf-life, safer transport |

| Modular Line Expansion | Phased capacity growth | Scales smoothly with market demand |

Conclusion

Pan-India distribution necessitates control, speed, or uniformity. Our industrial makhana processing lines, designed and built by Foodsure Machines, are engineered to expand with your business. With the support of our machines, you can confidently grow nationally, lower risk, and enhance quality. Let’s work together to create your next phase of development.

FAQ

What is an industrial makhana processing line?

It is a structured production setup where roasting, grading, and packing flow smoothly, with machines handling tasks that usually slow manual operations.

Who should invest in an industrial makhana line?

Processors expanding beyond local markets and supplying multiple regions benefit most, as manual systems become limiting.

What capacity does an industrial line handle?

Most lines start at around 50 kg per hour and can be expanded to handle multi-ton daily volumes as demand increases.

Does it reduce manual labour and losses?

Yes. Automation reduces handling, minimizes breakage, and delivers consistent product quality batch after batch.

Can it be scaled in stages?

Absolutely. Machines can be added gradually as orders grow, avoiding unnecessary upfront investment in unused capacity.