Over 70% of small mayonnaise plants struggle with inconsistent texture and high wastage. Between industrial emulsification vs high shear machines, which truly scales your factory? If your output stalls or costs soar, this blog reveals the hidden performance gaps your engineer must know to fix them.

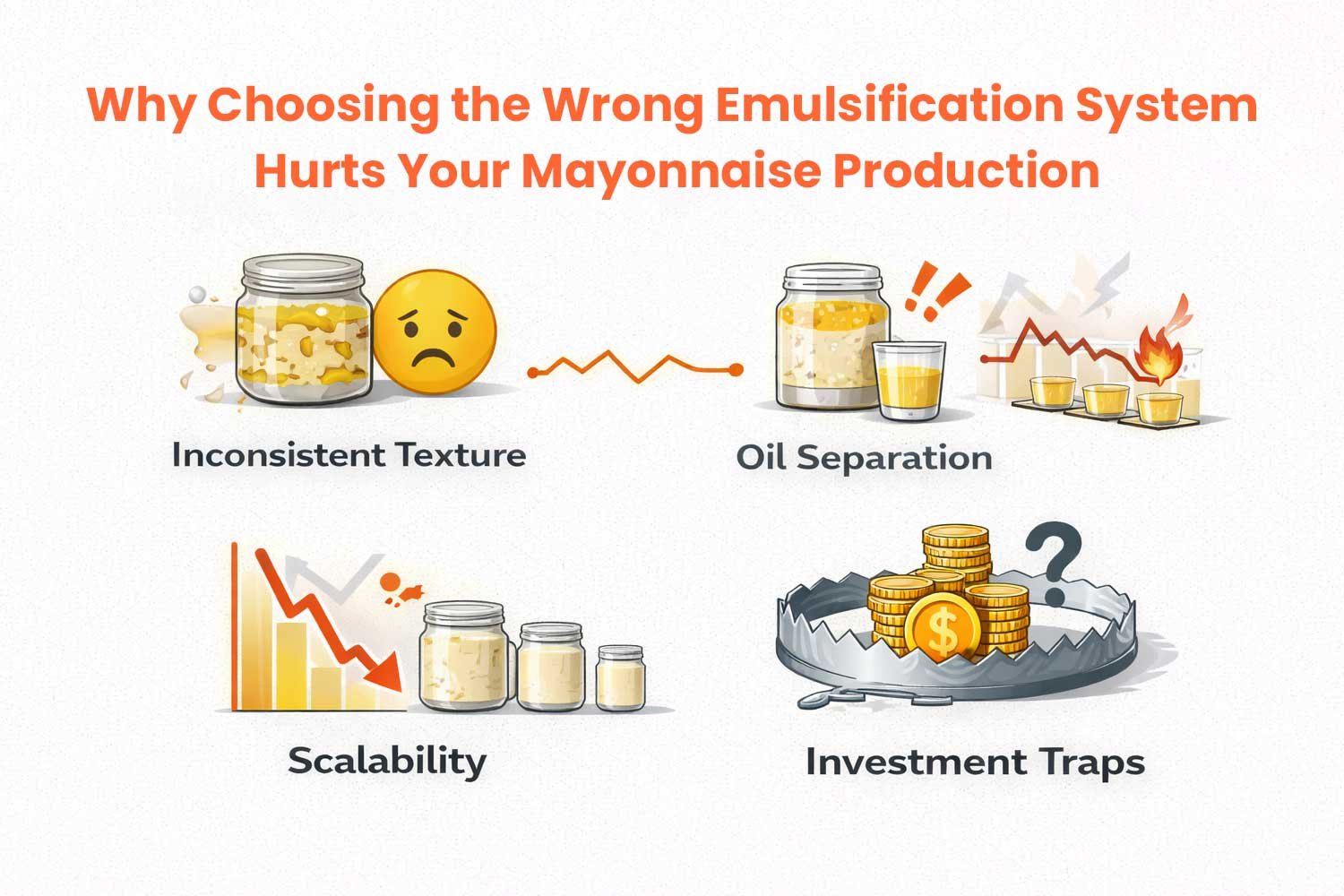

Why Choosing the Wrong Emulsification System Hurts Your Mayonnaise Production

When the emulsion system is improperly matched with mayonnaise mixing technology, surface quality, stability, and expandability can be compromised. This is especially true for small FPOs (Farmer-Producer Organisation) and start-up companies. An incorrect match between the emulsifying system and mayonnaise production can create discontinuities in oil-in-water emulsions, resulting in waste, rejection, and higher costs. The following are risks associated with improper emulsion systems for mayonnaise:

- Inconsistent Texture: Poor shear mixing results in uneven droplet sizes, leading to grainy or separated batches that result in 20–30% batch rejection for failing sensory standards.

- Oil Separation: Poor levels of homogenization will result in the formation of cream and a shelf life of less than 3 months, resulting in spoilage and recall due to oxidation.

- Scalability: Fixed-capacity batch mixers will add 15-20% to the cost per kilogram as production grows, or during scale-up, and will not allow for inline upgrading.

- Investment Traps: Startups will tend to over-purchase, oversized unitary systems or under-capacity, resulting in capital being locked up with no return on investment and non-compliance with FSSC 22000 standards.

What Is Industrial Emulsification?

Industrial emulsifiers are capable of producing stable emulsions using very high shear forces. The production of a uniform mayonnaise requires a uniform emulsification.

- How Industrial Emulsifiers Work: A rotor-stator model is made up of a fast-rotating rotor that fits inside a fixed stator. The rotor rotates at speeds up to 30 m/s, drawing the material into it, creating large shear forces that break the oil into 1-5μm droplets through viscous turbulence, and expelling the fine emulsifying mixture of droplets through the discharge valve. High-pressure versions of industrial emulsifiers employ a positive displacement pump to pump a liquid mixture through a valve at pressures between 100-2000 bar.

- Production Capacity and Industries: The production capacity of industrial emulsifiers ranges from 500kg/hr to 2,000kg/hr for batch mode production, while the same industrial emulsifiers in continuous-mode run can produce upwards of 5,000kg/hr. Commercial and industrial mayonnaise companies use industrial emulsifying systems to produce mayonnaise types that contain high oil levels (60%-80%) and also produce sauces and dressings.

- Best Applications for Industrial Emulsifiers: Industrial emulsifying systems are designed to accommodate very high continuous volumes and to be used in plants that operate on a continuous basis (24/7).

Also read: Mayonnaise Machine Price India: 2026 Cost Guide & ROI

What Is a High-Shear Mayonnaise Machine?

Through intense mechanical force using rotor-stator technology, high shear mayonnaise machines create stable emulsions (oil droplets evenly dispersed in water phases).

- The rotor-stator principle is as follows: A high-speed rotating rotor creates a narrow gap between itself and the stationary stator. The force of the rotating rotor draws materials into this narrow gap, where experienced tip speeds of up to 30 m/s. This shear rate creates turbulence and cavitation, which results in the breaking apart of the oil droplets into 1-5μm size droplets.

- For mayonnaise producers to maintain a consistent product texture throughout the life of their products, it is essential to utilise the higher shearing rates of the high shear mayonnaise machines. The use of low shear (below 10,000s-1) results in inconsistently sized oil droplets, which produces grainy or split mayonnaise and contributes to a significantly shorter shelf life.

- The average output range of units is 50-500kg/h. This is the ideal output range for pilot plants, start-ups, and mid-scale FPOs that are looking to transition from lab to commercial without making excessive investments in equipment.

Industrial Emulsification vs High Shear: A Clear Side-by-Side Comparison for Mayonnaise Plants

| Factor | Industrial Emulsification | High-Shear Mayonnaise Machine |

| Texture control | Superior, ensures ultra-smooth, stable emulsions even in large batches | Good for small batches, but may show slight graininess in high-volume production |

| Batch consistency | Very high, replicable results across multiple shifts | Moderate; variations can occur when scaling up |

| Oil incorporation | Optimal, handles higher oil ratios efficiently | Adequate; may require adjustments for richer recipes |

| Scalability | Excellent, ideal for large industrial plants | Limited to small-to-medium production |

| Maintenance | Medium-high, specialised parts require skilled technicians | Low-to-medium; simpler design, easier to clean |

| Cost efficiency | Best for large-scale plants, ROI improves with volume | Best for small setups; lower upfront cost, but less scalable |

Industrial Emulsification vs High Shear: Which System Fits Your Factory Size?

The production of mayonnaise is broken down into three groups of producers depending on their needs, small (usually high-shear emulsifiers)manufacturers and growing brands (budgeting for 1 to 2 tons/day), and multi-shift industrial plants.

- The first group typically uses high-shear machines with low start-up costs (usually well below $20,000), allowing flexibility with recipe development (200 to 1000 kg/day). For India, these are the preferred emulsification systems for scaling from lab tests to commercial production.

- The second product type is industrial emulsifiers with a cost associated with producing products at 1-2 tons per day, plus a 30% lower rejection rate than high-shear production due to inline processing, which further enables these emulsifiers to provide a cost-effective means to transition pilot products to commercial products by allowing incremental modularity, providing a more efficient processing for 8-hour shifts.

- The third group of producers are fully equipped industrial systems, and these are the most successful for achieving large volumes of consistent product (producing at least 2 to 5 tonnes of product) continuously (operating at least 24/7) and offering products compliant with the Food Safety System Certification (FSSC 22000).

Also read: Mayonnaise Manufacturing Plant: Setup, Machines & ROI Guide

Conclusion

Industrial emulsification vs high shear machine makers have a similar function; so, it is not about trends, but rather, it is about what works better. Foodsure Machines is working with the manufacturer to find the appropriate mayonnaise making machine for the application, capacity, and formula to meet their needs. The design engineers at the company focus on producing emulsions that maintain their texture, have the ability to produce at a large scale, and are cost-effective over time.

Frequently Asked Questions

What is the main difference between industrial emulsification vs high-shear machines?

Industrial emulsification is designed for continuous high-volume production, while high-shear machines are better suited for smaller, controlled batch processing.

Which machine gives better mayonnaise texture?

At higher production volumes, industrial emulsification systems deliver a more uniform and stable mayonnaise texture.

Are high-shear machines enough for commercial mayonnaise production?

Yes, high-shear machines work well for pilot plants, startups, and mid-scale commercial mayonnaise production.

Which system handles higher oil content better?

Industrial emulsification systems manage high oil ratios with greater stability and lower risk of separation.

What output range suits high-shear mayonnaise machines?

High-shear mayonnaise machines typically handle production volumes between 50 and 500 kg per hour.

When should a plant upgrade to industrial emulsification?

Upgrading makes sense when daily output crosses 1 to 2 tons or when the plant shifts to continuous processing.

Which option reduces batch rejection rates?

Industrial emulsification reduces rejection rates because inline processing keeps batches consistent.

Are industrial emulsifiers more expensive to maintain?

Yes, industrial emulsifiers generally have higher maintenance costs compared to high-shear machines.

Which system is better for FPOs and startups?

High-shear machines are better for FPOs and startups due to lower upfront investment and operational flexibility.

Can high-shear machines scale with demand?

Only up to a certain point. Beyond that, efficiency drops and industrial emulsification becomes necessary.

Which machine supports FSSC 22000 compliance better?

Industrial emulsification systems align better with FSSC 22000 compliance at larger production scales.

How do I choose between industrial emulsification vs high-shear machines?

Choose based on required capacity, recipe complexity, compliance needs, and long-term growth plans.