Uniformity, speed, and control. These are not optional in food processing. They are the baseline. Even if you are handling nuts, seeds, or something as delicate as makhana, the roasting step affects product quality. And if it’s unpredictable, your entire operation starts leaking profit. That’s where modern tunnel roasters come in, especially the food-grade tunnel roaster 50 kg/hour models now being adopted by serious small and mid-scale processors across India.

This blog gets into the details: how these roasters are built, what makes them efficient, and why they are showing up in every smart food industry tunnel roaster supplier. If you are scaling a snack brand, understanding this equipment is not optional; it’s the starting point.

What Is A Tunnel Roaster

This 50 kg/hour tunnel roaster feed system does one thing reliably well: it makes roasting consistently precise, batch after batch. Instead of tossing ingredients in a pan or drum and hoping for even results, this system moves food, even its makhana, peanuts, or anything similar, through a controlled heating tunnel on a conveyor belt. That means every piece gets the same treatment, every single time.

Key Components And How They Work

A food-grade tunnel roaster 50 kg/hour might look simple from the outside, but it’s a carefully engineered system. Here’s an overview of its main components and what they do:

-

Heating Zones

These are the heart of the tunnel. Multiple sections, each with its own temperature and airflow settings, let you fine-tune how the heat hits the product. The result? Consistent roasting from starting to end.

-

Digital Control Panel

This is where the operator takes control. You can adjust speed, temperature, and time with a precision roasting system for food factories. And because it’s all visible in real time, you are not guessing, but you are managing.

-

Conveyor Belt System

The food-grade tunnel roaster 50 kg/hour belt spaces out the kernels evenly, moves them at a regular pace, and makes sure each one gets equal exposure. That’s how you get uniform results without burning or undercooking anything.

What this really means is: no more rework, no more wastage, and industrial makhana machines for makhana process that finally matches the scale of your operation.

Comparison Of A Tunnel Roaster Vs Conventional Systems

The table below shows the major comparison of a food-grade tunnel roaster 50 kg/hour when compared to a conventional drum roaster.

| Feature | Conventional Drum Roaster | Modern Tunnel Roaster |

| Capacity | 15–20 kg/hour | 50 kg/hour |

| Heat Control | Manual | Digital, multi-zone |

| Labor | High | Low |

| Roasting Quality | Inconsistent | Uniform and repeatable |

| Energy Usage | Less efficient | Optimized fuel or electric |

| Batch Predictability | Variable | Highly consistent |

| Automation | Minimal | Fully programmable |

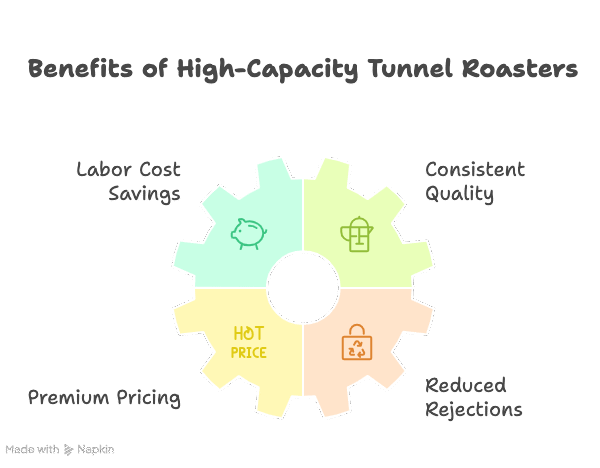

Maximize ROI And Scale Profitably With High-Capacity Tunnel Roasters

Switching to a modern food-grade tunnel roaster 50 kg/hour transforms your operation by automatic nut roasting equipment key processes and ensuring precision roasting system for food factories. This not only improves efficiency but also raises product quality, creating a strong competitive advantage in today’s food roasting equipment supplier.

-

You save serious labor costs

Instead of 5–10 workers constantly watching over pans or drum heating tunnel, you need just 1–2 people to run the food industry tunnel roaster supplier. Everything else is automated temperature control, timing, and movement. Over time, that 40–60% drop in labor costs adds up.

-

Buyers pay more when the quality stays the same

Roast consistency isn’t just nice to have, but it directly affects how much you can charge. With uniform heat zones and controls, you hit the same roast profile every time. That’s what buyers want and it allows you to charge a premium.

-

You lose fewer deals to quality issues

If you are selling to exporters or big buyers, rejections cost real money. They expect uniformity, batch after batch. Precision food roasting machines for food factories delivers exactly that. You stop wasting product and opportunities because of over-roasted or under-roasted batches.

Technical Specifications Of The 50 Kg/Hour Tunnel Roaster

The 50 kg/hour tunnel roaster is built with industrial-grade components and advanced control systems. Below are the detailed specifications that highlight its robust design and safety-focused features, making it ideal for modern food manufacturing equipment.

| Specification | Details |

| Machine Length | 10–14 feet |

| Material | Stainless Steel (SS304 food-grade) |

| Belt Width | 400–600 mm (customizable) |

| Temperature Range | Up to 250°C |

| Roasting Time | Adjustable from 5–25 minutes |

| Power Source | 3-Phase Electric / LPG / Diesel |

| Control System | PID + PLC options |

| Maintenance | Modular design, easy access hatches |

| Safety Features | Thermal protection, emergency kill switch. |

Makhana Processing With Tunnel Roaster Integration

A modern commercial food-grade roasting machine handling 50 kg/hour is best utilized as a key module within a fully integrated snack processing line.

1. Raw Cleaning: Dust & Husk Removal

Everything starts with clean input. Raw kernels go through aspirators and magnetic traps to pull out dust, husks, stones, and stray metal. This isn’t just about hygiene; it protects your equipment and lays the groundwork for smooth, consistent processing later.

2. Grading: Size Sorting

Next comes grading. The cleaned product moves through an automatic nut roasting equipment grader that separates kernels by size. Why does this matter? Because even roasting depends on consistent sizing. If you want even color, crunch, and cook time, this step is non-negotiable.

3. Roasting: Precision Tunnel Roasting

This is where the real transformation happens. The kernels then travel through the automatic nut roasting equipment on a food-safe belt through a commercial food-grade roasting machine with programmable heating zones. The result? Even roasting, less than 8% wastage, and a steady output of 50 kg/hour. No overcooked edges. No raw centers. Just batch after batch of consistent quality.

Transform Roasting With Foodsure Machines

Foodsure Machines is changing how roasting gets done. Our 50 kg/hour tunnel roaster does not just roast; it delivers consistent results, batch after batch, with zero manual trial. Programmable heating zones keep temperatures locked in, while commercial food-grade roasting machine move the product smoothly through the system. The real power? It fits right into a full production line. From grading to cooling to final packing, it all connects.

FAQ

1. What makes a tunnel roaster better than traditional batch roasting?

It comes down to control and consistency. With a tunnel roaster, every kernel moves through the same heat, at the same pace, every time. That means even roasting, fewer burnt or raw pieces, and a huge drop in waste. You’re not guessing. You’re producing exactly what you planned, batch after batch

2. How much can a 50 kg/hour tunnel roaster produce daily?

Run it for a regular 8 to 10-hour shift, and you’ll roast 400 to 500 kg without breaking a sweat. It doesn’t need a full team either. One or two people can manage the whole operation, which means lower labor costs and less chaos on the floor.

3.Can this roaster be integrated with other processing equipment?

Yes, and that’s where it shines. You can connect it directly to grading machines on the front end and cooling, flavoring, or packing systems on the back end. What you get is a smooth, end-to-end production flow that saves time and keeps quality tight at every step.

4. What temperature does a Food-Grade Tunnel Roaster operate at?

It typically operates between moderate to high roasting temperatures depending on the product.

5. What is the main purpose of a Food-Grade Tunnel Roaster?

Its purpose is to deliver consistent, high-quality roasting in a continuous flow.

6. What are the types of roasting systems used in tunnel roasters?

They usually include electric, gas-fired, and infrared roasting systems.

7. How does a Food-Grade Tunnel Roaster 50 Kg/Hour work?

It moves food through a heated tunnel on a conveyor for even, controlled roasting.

8. What is the working principle of a Food-Grade Tunnel Roaster?

It uses continuous heat transfer while the product passes through at a steady speed.

9. Which type of tunnel roaster is better?

The best type depends on the required energy source, product type, and roasting precision.

10. Can a Food-Grade Tunnel Roaster reach very high temperatures?

It can reach high roasting temperatures but is not designed for extreme industrial heat levels.

11. What are the types of tunnels used in food roasting?

They include hot-air tunnels, infrared tunnels, and gas-fired roasting tunnels.

12. What are the key functions of a Food-Grade Tunnel Roaster?

Its key functions are roasting, drying, heat transfer, and continuous product movement.