Many people in India are now gravitating towards energy bars as a snack choice, and entrepreneurs are eager to satisfy that need. The main challenge is scaling production without sacrificing quality or speed. An energy bar machine allows you to leverage your tasty snack for a consistent source of income.

Energy Bar Market Insights Every Manufacturer Should Know

Energy bars are rapidly growing in India as part of the overall rise of healthy snacking, a trend driven by increasing consumer awareness about nutrition and fitness. Industry forecasts expect the healthy snacks sector in India to continue to grow at over 7% CAGR to beyond 2030 as urban consumers increasingly shift to practical, protein-based energy bars that can conveniently fit into their active lifestyles. Besides, growing disposable income, wellness trends, and lifestyles have also positively influenced the growth of the demand for energy bars with clean-label or natural-based ingredients.

What is an Energy Bar?

Energy bars are combinations of nutrients, and they are an easy, quick form of energy, protein. Energy bars can be put into three types: protein bars (high protein, low sugar), cereal bars (high protein and fiber with whole grains), or health & energy bars (vitamins or minerals or other functional ingredients).

Problems Every Manufacturer Faces in Energy Bar Production

- Manual handling results in inconsistent quality with textures and taste, which could affect brand image. Small batch production capacity has struggled to keep up with demand in growing markets.

- Labor costs are high because operating in a manual way decreases profit margins. Shelf-life issues arise when energy bars are not made, packaged, or stored properly, resulting in bar spoilage.

An automated snack bar production line with bar machines will facilitate consistent output, increased throughput, improved shelf-stability, and considerably reduced labor and operating expenses. Energy bar manufacturing equipmentfor the energy bar industry will also allow startups to resolve some of the toughest challenges.

How an Energy Bar Machine Solves Production Challenges

- It achieves full automation of the snack bar production line process from mixing, filling, and packaging at the highest efficiencies and levels of scalability. Produces energy bars of the same size and flavor, ensuring both quality and consistency.

- Nutrition bar manufacturing is able to produce hundreds of energy bars each hour to satisfy the increasing consumer demands in the marketplace. Significantly reduces manual labour and human errors to assist in lowering labour costs.

- Snack bar equipment is constructed with food-grade stainless steel to safely and hygienically handle the food. 100% able to suitable for both small-scale and large producers with fully automated lines and processes.

- Programmable controls to allow the operator to accurately control the process from mixing, extruding, cutting, and cooling. Energy bar equipment helps reduce waste and allows for maximum shelf life to deliver a longer product through processing, and reduces packing processes. A utility with a recipe bar allows for variability in the product capabilities produced.

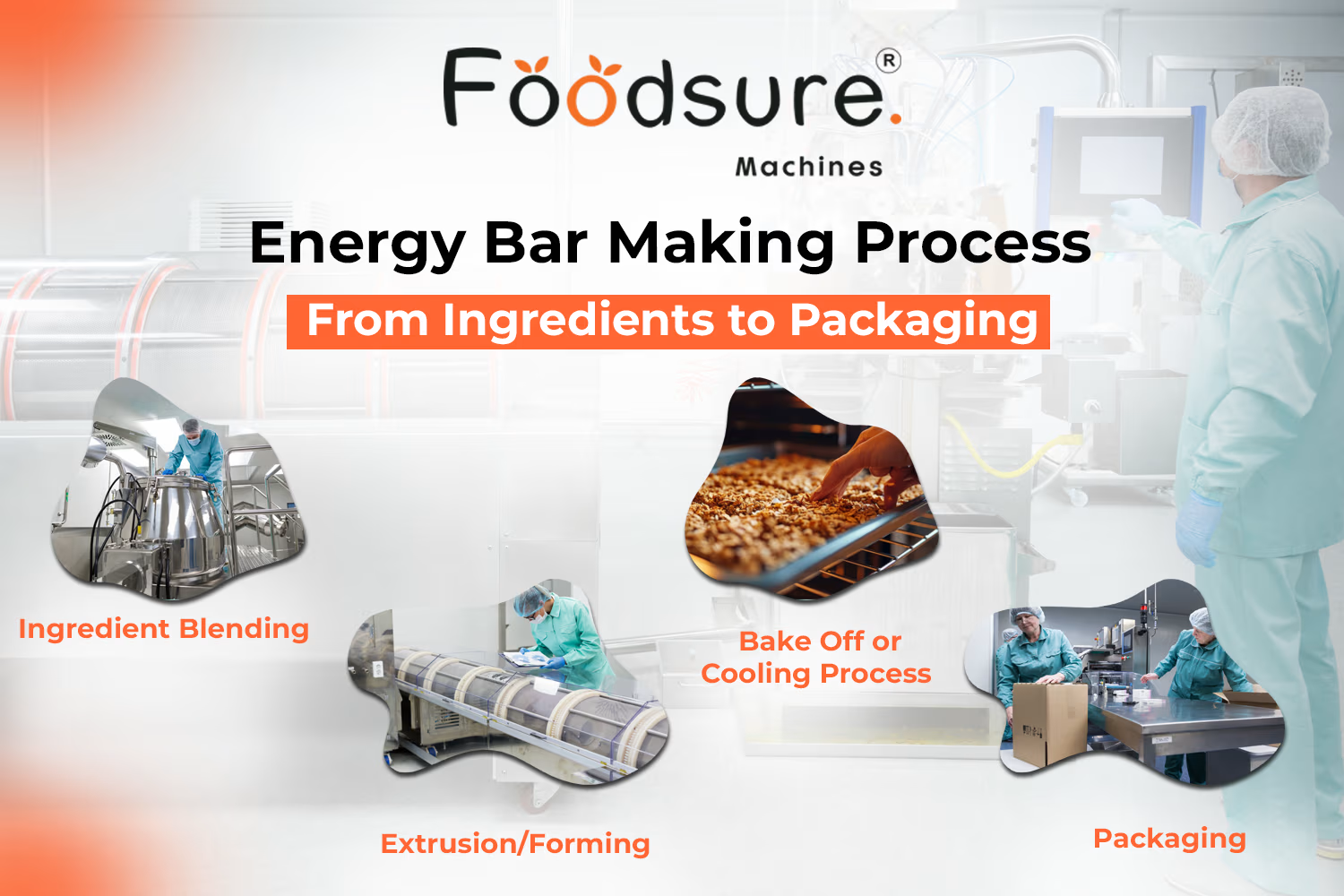

Energy Bar Making Process: From Ingredients to Packaging

1. Ingredient Blending

Industrial mixers thoroughly blend protein powders, oats, nuts, sweeteners, and binders into a consistent dough. This ensures an even distribution of nutrients, taste, and texture, all critical components to consider for preparing pre-made orders in bulk.

2. Extrusion/Forming

Snack bar equipment extrudes dough into various sizes and shapes, and directly forms it into bars. This process creates standardization in size and weight. This process allows for ensuring consistent dimensions for the prepackaged bars, while providing flow and scale for the whole process, for consistent expected production outputs.

3. Bake Off or Cooling Process

The bars are baked or cooled depending on the recipe. Baking is to develop and strengthen the final texture and durability for shelf-life, while cooling ensures heat-sensitive nutrients are preserved and intact. This process is where the final texture, firmness, and stability of the bar are produced.

4. Energy Bar Packaging Machine

The bars are placed on conveyor belts and transferred to automated or manual pack lines. The bars are either individually flow wrapped or packed in a box. Properly packaged for the consumer, the final product will help keep it safe for the consumer, protect it from contamination, and enhance the visual appeal of the product.

Understanding the Energy Bar Manufacturing Plant Cost

| Item | Description | Estimated Cost (INR) | Notes |

| Energy Bar Machine | Small-scale to semi-automatic machine | 2,50,000 – 7,50,000 | Depends on capacity & automation |

| Installation & Commissioning | Set up at the facility, calibration, and initial training | 20,000 – 50,000 | One-time cost |

| Optional Accessories | Molds, cutters, wrappers, ingredient hoppers | 15,000 – 60,000 | Optional, depending on production needs |

| Electricity / Power | Monthly power consumption | 3,000 – 8,000 | Based on machine size and usage |

| Labor | Operators/helpers | 10,000 – 25,000 per month | For small production units |

| Other CAPEX | Tables, storage, safety equipment | 25,000 – 50,000 | One-time investment |

| Total Estimated Setup Cost | CAPEX + First 3 months OPEX | 3,23,000 – 8,93,000 | Varies by scale and location |

Conclusion

At Foodsure Machines, we aim to make life easier for small manufacturers and businesses to produce energy bars in an efficient and cost-effective manner. Our nutrition bar manufacturing will equip your business with the ability to produce a quality energy bar in volume and with limited labor at an excellent return on investment and at one of the best prices in the country. What are you waiting for? If you are ready to start selling your energy bar production, we can help you start production today and grow your business!

Have a Question? Let’s Connect!

Please reach out to us anytime via phone or email.

FAQ

Q1. What market entry exists for the energy bar machines market in India?

Ans: There is a growth momentum happening in the energy bar market, and therefore, there is a market entry opportunity for energy bar machines to assist small producers and new entrants in optimizing their production time.

Q2. What nutrition bar making machine is best for small producers in India?

Ans: A small semi-automatic machine from a solid manufacturer and brand, such as Foodsure Machines, is your best option. A small or semi-automatic machine still delivers craft quality, but with lower labor.

Q3. What is the benefit of an energy bar machine?

Ans: An energy bar machine provides a consistent quality, improves slow production time, and reduces labor rate cost, which provides the highest roi.

Q4. How long does 1 kg of energy bars last?

Ans: Depends on consumption, usually 10–12 bars per kg.

Q5. What is the size of the energy bar market in India?

Ans: India’s energy bar market is growing rapidly, estimated over ₹1,000 crore.

Q6. What is the price of an energy bar machine in India?

Ans: Prices start around ₹3–5 lakh, depending on capacity and automation.

Q7. How much raw material is needed to make 1 kg of energy bars?

Ans: Approximately 1 kg of mixed ingredients yields 1 kg of energy bars.

Q8. How much protein is in 1 energy bar?

Ans: Typically 8–12 grams per standard 40–50 g bar.

Q9. How profitable is making energy bars?

Ans: Profit margins can range from 20–40% per batch.

Q10. Which is better, energy bar machine or protein bar machine?

Ans: Energy bar machines are ideal for quick snacks; protein bar machines suit high-protein bars.

Q11. Do nutritionists recommend energy bars?

Ans: Yes, in moderation, for active lifestyles or quick energy.

Q12. How to produce bars with specific protein content?

Ans: Adjust ingredients in the recipe; machines handle shaping and compressing.