India’s makhana demand is growing at 12% CAGR, but processors still struggle with inconsistent grading, rising labor costs, and export rejections. What’s the real solution when manual sorting can’t match global standards? This guide breaks down market insights, why optimization matters now, and how automated sorting & grading machines can transform your output with Foodsure Machines’ support.

Why 2025 Makhana Units Can’t Grow Without Automated Sorting Machines

Makhana is gaining global popularity for its health benefits. However, meeting domestic and international demand requires strict quality control and high processing volumes, which cannot be done with manual makhana processing.

By 2027, experts predicted that the global makhana market is projected to reach USD 60 billion, driven by the growing demand for superfoods (source). To get into this growing market, investing in automated makhana sorting and grading machines is no longer optional; it’s a strategic move.

2025 Demand for Makhana Sorting & Grading Machines in India

Market Growth Drivers

- Health Consciousness Surge: Rising lifestyle diseases like diabetes and heart ailments are pushing Indian consumers toward healthier snacks. Makhana, a low-calorie superfood, is benefiting from this trend, supported by government health campaigns. By 2023, over 40% of urban households preferred healthy snacks like makhana (Source).

- Growing Demand for Organic Snacks: With 2.8M hectares under organic cultivation by 2022, India leads in Asia’s organic production. Makhana has emerged as a top choice among health-conscious consumers.

- E-commerce Expansion: India’s 660M smartphone users have enabled widespread distribution of makhana. Over 25% of makhana sales now occur online, by platforms like BigBasket and Amazon.

Read More: Makhana Machine Trends 2025: Industry Growth & New Opportunities

Market Challenges

- Low Consumer Awareness: Only about 20% of rural Indians are aware of makhana’s health benefits, limiting market growth in smaller towns and villages.

- High Manual Production Costs: Labor-intensive harvesting and water scarcity in Bihar and West Bengal drive up costs. With labor wages averaging INR 350/day, scaling production remains difficult without mechanization or subsidies.

To reduce such high manual production costs, sorting & grading machines market an important role in your makhana business.

How Automated Grading Machines Increase Output 3X & Cut Costs Fast

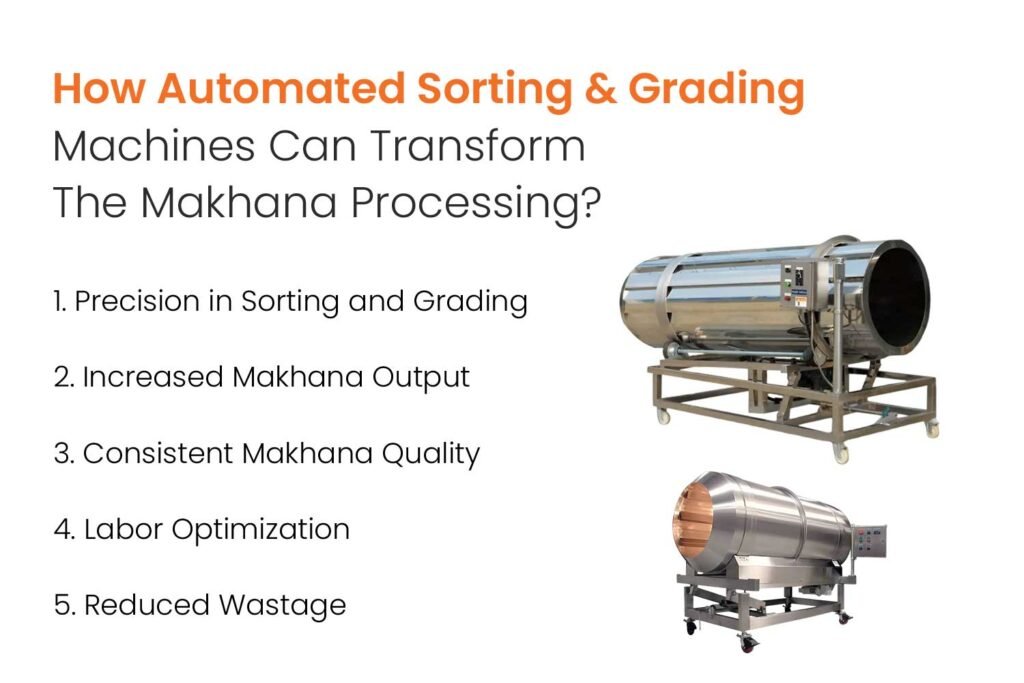

Most small processors in Bihar lose 10–15% yield due to manual inaccuracies. Our Automated makhana grading machines are made to solve all the problems of manual makhana production. Here’s how automated sorting & grading machines can transform the makhana processing:

-

Precision in Sorting and Grading

Our automatic makhana grader is made with high resistance to corrosion and rust and is excellent for food-grade applications. They help to sort the makhana by their:

- Size

- Color

- Surface defects

- Density

-

Increased Makhana Output

Makhana grading plant can handle up to 100-300 kg/hr, hence increasing the makhana production and saving time.

-

Consistent Makhana Quality

Automated makhana processing machines maintain consistency across batches, helping you meet strict buyer specifications, especially for exports to the USA, Europe, and the Middle East markets.

-

Labor Optimization

Instead of needing 7-8 people for sorting, you need just 1-2 operators for running the machine, reducing labor costs by up to 60%.

-

Reduced Wastage

Automated sorting & grading machines help to achieve wastage rates below 1%, leading to significant material savings over time.

Read More: From Chaos To Consistency: Why Every Makhana Unit Needs A Precision Grading Machine

Key Features That Make Automated Makhana Sorting Machines Worth the Investment

When you choose us, you invest in cutting-edge technology backed by industry expertise. Some of the features of automated sorting & grading makhana machines include:

- Material: Contact Parts- Stainless Steel 304 (SS304) and food safe size grading equipment.

- Material Sieving: Designed for separating materials by size, effectively sorting from larger to smaller sizes.

- Properties: High resistance to corrosion and rust, excellent for food-grade applications, durable, and easy to clean.

- Applications: Commonly used in environments where hygiene is critical, such as in food processing equipment and medical instruments.

- Power Load: 0.75 KW

- Cost: INR 150,000.00(makhana grading machine price)

Why Leading Makhana Units Trust Foodsure’s Automated Sorting Machines

Foodsure Machines is your trusted partner for makhana production in India and worldwide due to:

High-quality & Durable Machines

Our machines are made for powerful performance and longevity, guaranteeing a strong return on your investment.

Trunkey Solutions

From plant layout planning to complete production of makhana, like grading, roasting, seasoning, and packaging, to equipment supply, installation, and operator training and after-sales support, we deliver a full turnkey setup that gets your plant running smoothly and profitably from day one.

Advanced Technology

Our machines are made with the latest technology to ensure efficient, consistent, and high-quality makhana processing.

Complete Support

We support installation, training, and after-sales to ensure smooth operations and increase profits.

Global Standards

Our makhana machines adhere to international quality and safety standards, making them suitable for manufacturers worldwide.

The Future of Makhana Processing: Why Automation Will Decide Market Winners

Industry reports project the global makhana market to exceed USD 60 billion by 2027. Buyers, especially from the US, EU, and Middle East, now demand product consistency and compliance with international food safety standards.

This makes it essential for makhana manufacturers in India to:

- Adopt automated sorting & grading machines

- Ensure consistent product quality

- Reduce dependency on manual labor

- Increase production capacity to meet large-scale demand

Optimize Your Makhana Production With Foodsure Machines!

We are your trusted partner for optimizing your makhana production to meet your business needs. From installation to after-sales, you have full support and guidance from our side. Foodsure Machines will provide you with turnkey solutions, i.e, from planning to market launch of makhana and help you to know how to optimize makhana production that can help for better success in your makhana business.

FAQ

Q1. What is an automated sorting system?

An automated sorting system uses sensors and precision technology to separate makhana based on size, color, and defects—without manual labor.

Q2. What are automated grading systems?

Automated grading equipment classify makhana into accurate quality grades to ensure consistent output for retail and export.

Q3. What machine is used for grading?

A makhana grading machine uses multi-layer sieves and automated controls to sort seeds into uniform size categories.

Q4. What is food sorting and grading control?

It’s the automated process of monitoring, detecting, and classifying food items to maintain quality, hygiene, and batch consistency.

Q5. What is an automated sorting and grading machine?

A machine that automatically sorts and grades products by size, weight, color, or quality.

Q6. What do automated grading systems do?

They classify products accurately using sensors and AI-based analysis.

Q7. What machine is used for product grading?

Optical, weight-based, and color-sorting machines are commonly used.

Q8. What is sorting and grading in food processing?

Sorting separates items; grading ranks them by quality or specification.

Q9. What are the main types of automation in sorting systems?

Fixed, programmable, flexible, and integrated automation.

Q10. What is ASRS used for in processing units?

For automated storage and retrieval of sorted products.

Q11. What are the five basic components of an automated sorting system?

Sensors, conveyors, controllers, actuators, and software.

Q12. What is an example of a sorting machine in food plants?

A color sorter used for nuts, seeds, and grains.