Bihar grows nearly 90% of India’s makhana, but a surprising number of units still sort it all by hand. Roasting became a guessing game. Some seeds burned, while others remained half-cooked, and wastage increased by 20–25%. Between 2020 and 2024, the market maintained an impressive 6.7% CAGR.

Local buyers pushed prices down by 10–15% because the product just didn’t look right. Meanwhile, more than 15 workers were stuck doing one job, sorting without actually fixing the problem. Labor costs increased, but quality remained unchanged. That’s the reality that too many makhana units are still living with when a Automated Makhana Grading Machine could change everything.

The Turning Point: Investing In A Precision Automated Makhana Grading Machine

In early 2023, this unit made a smart move: the team invested in a high-precision makhana grader and built it to do one job and do it right. It sorted every kernel by size with scientific accuracy. Small, medium, large, and everything in between were separated by industrial makhana equipment. There was no guesswork, and no re-sorting. Just clean, and reliable automated makhana grading machine that took the uncertainty out of the process and gave them full control over quality from the start.

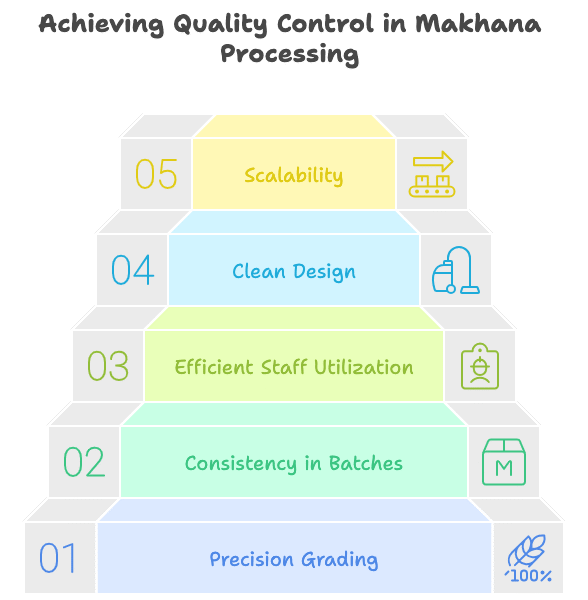

Why Automated Makhana Grading Machine? Let’s break It Down:

- Precision and speed: It could handle thousands of kilos per hour. With no delays, no human errors. Just clean, reliable grading at scale.

- Consistency, batch after batch: Uniform sizes meant better roasting, neater packaging, and zero surprises in the final product. That’s what premium buyers want.

- Fewer hands, more skill: Since the makhana sorting machine did the heavy lifting on sorting, staff could shift to other important roles. That saved time and made better use of the team’s skills.

- Clean design, clean product: The stainless steel build wasn’t just sleek; it made cleaning simpler and upheld food safety without extra effort.

- Ready to grow: The best part? It fit right into their existing setup and left room to expand. They didn’t need to overhaul the line. Just plug in and scale when ready.

What this really means is the processor stopped guessing and started building a system that worked with them, not against them.

Implementation: How the Machine Changed Daily Operations

Before The Machine

Everything was done by hand. Workers sat around large trays, picking through piles of makhana, trying to sort by size. It was slow, exhausting, and honestly, not very effective. Mixed-size kernels still ended up in the same batch. That’s where the real trouble started. Roasting became unpredictable; even some kernels stayed raw, and others got burnt.

Wastage shot up, and because grading took so long, shipping was delayed, which resulted in missed orders and lost time. The whole operation was stuck in a cycle that just didn’t scale. Introducing a high-precision makhana grading plant is what breaks this cycle, turning unpredictable results into consistent quality, higher margins, and business growth.

Post-Installation Process With Automated Makhana Grading Machine

- Loading Made Simple: Makhana kernels are directly fed into the machine’s hopper with no manual trays, no bottlenecks.

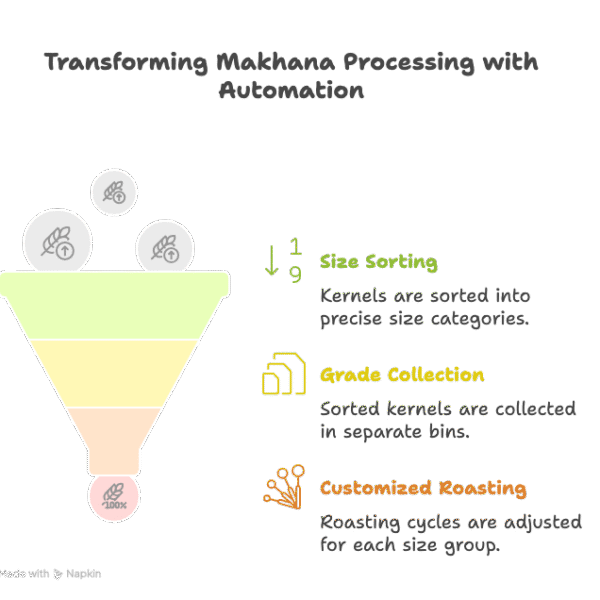

- Scientific Size Sorting: Built-in precision food safe size grading machine separate kernels into exact size categories: small, medium, large, and sub-sizes. With no overlaps, no errors.

- Clean, Sorted Output: Each grade of makhana is collected in separate bins, fully ready for roasting or packaging without extra handling.

- Roasting Adjusted by Grade: Separate roasting cycles are now customized to each size group. No more guesswork, just consistent, quality roasting every time.

Case Study: Revenue Growth & Profitability Increase By Makhana Machine

Here’s the thing: once the automated grading equipment is in use, the numbers start telling a different story. Within six months, the unit’s monthly increase in makhana factory automation solutions revenue jumped by 32%. They weren’t just moving more product; they were moving it smarter. Makhana grading machine price solutions climbed from around ₹45 lakhs to ₹59 lakhs a month. And that wasn’t just volume talking. Better pricing from consistent quality and less wastage meant stronger margins too.

| Metric | Before Automation | After Automation | Percentage Improvement |

|---|---|---|---|

| Daily grading capacity | 400 kg | 600 kg | 50% |

| Sorting time per batch | 4–6 hours | <1 hour | ~80% reduction |

| Wastage | 20–25% | 7–8% | ~70% reduction |

| Export rejections | 15–20% | 4–5% | ~75% reduction |

| Price per kg (avg.) | ₹300 | ₹345 | 15% |

| Labor cost for sorting | ₹60,000 / month | ₹36,000 / month | 40% reduction |

| Monthly revenue | ₹45,00,000 | ₹59,00,000 | 32% |

Why This Matters For Bihar’s Makhana Sector: Unlocking Growth & Global Potential

Automated makhana grading machine isn’t optional anymore; it’s the foundation of a serious business looking to use a makhana size grading machine. When you get precision right from the beginning, everything else gets easier. You waste less, you need fewer hands on the line, and you move product faster. Buyers notice the consistency, and that’s what gets you better prices and repeat orders. Most units recover the cost of the automatic grading machine in under a year just through higher margins and smoother operations. And here’s the bigger picture: when more units in Bihar makhana sector upgrade, the entire region becomes stronger in the export market. That’s how you shift from just surviving to building a brand that lasts.

Grow Your Makhana Profits With Foodsure Machines

Foodsure Machines gives makhana processors a smarter way to scale. Our makhana size grading machine sorts kernels by size with real accuracy, no guesswork, no waste. That alone makhana processing machine, like roasting, packaging, and pricing. But we don’t stop there. Our full line of machines, roasters, flavor coaters, conveyors, and hygienic packers is built to work together. So instead of juggling disconnected equipment, you get one clean, efficient setup. The result? Uniform quality, fewer labor hours, and makhana that’s ready for export without the usual stress. If you are looking to grow, this is the kind of system that gets you there.

READY TO INCREASE YOUR PROCESSING REVENUE?

Upgrade to Automated Grading and Improve Profitability

Discover how automated grading systems help food processing units improve product consistency, reduce manual errors, and increase revenue. Foodsure Machines provides complete support—from equipment selection to commercial production setup.

FAQ – Automated Makhana Grading Machine

Q1: How did automated grading impact the Bihar makhana unit’s production?

Sorting that once took hours was completed in minutes with accurate sizing, cleaner batches, better roasting, and far less waste—without heavy labor dependence.

Q2: What caused the 32% revenue increase after installing the grading machine?

Consistent quality fetched better prices, waste dropped, labor costs reduced, and revenue rose from ₹45 to ₹59 Lakhs due to precision, not luck.

Q3: Why is automated grading essential for makhana processors today?

Buyers now demand uniformity, especially for exports. Automated grading ensures consistency, lowers overhead, and supports long-term growth.

Q4: How is makhana graded using an Automated Makhana Grading Machine?

The machine uses sensors and automated sorting to grade makhana by size, shape, color, and visible defects.

Q5: What is the cost of an Automated Makhana Grading Machine?

Costs vary from mid to high range depending on capacity, technology, and automation level.

Q6: How to check makhana quality with an Automated Makhana Grading Machine?

Vision sensors instantly detect size variation, purity, and imperfections to assess quality.

Q7: Is investing in an Automated Makhana Grading Machine profitable?

Yes. It increases speed, cuts labor costs, improves consistency, and raises overall profitability.

Q8: How much makhana can the machine process per hour?

Most machines process hundreds of kilos per hour depending on model and workflow.

Q9: What is the cost of grading 100 g of makhana with the machine?

Due to high-capacity automation, the per-100g grading cost is extremely low.

Q10: Who supplies Automated Makhana Grading Machines?

They are supplied by specialized agri-automation and food processing machinery manufacturers.

Q11: How many makhana pieces can the machine grade per hour?

Thousands of makhana pieces can be graded per hour with high accuracy.

Q12: Which state uses Automated Makhana Grading Machines the most?

Bihar leads usage due to large-scale makhana farming and processing operations.