Most makhana businesses hit a quiet wall around the 1,000 kg/month mark. Orders are coming in, machines are running daily, yet growth feels oddly stuck. You’re producing more than a startup, but not enough to feel stable or relaxed.

This is usually when loan EMIs start pinching, distributors ask for tighter timelines, and every delay feels expensive. A makhana machine scale-up isn’t just about higher output; it changes how time, money, and risk behave inside your factory. Beyond 1,000 kg/month, the rules of production shift, and this blog breaks down what actually changes, before the costs catch you off guard.

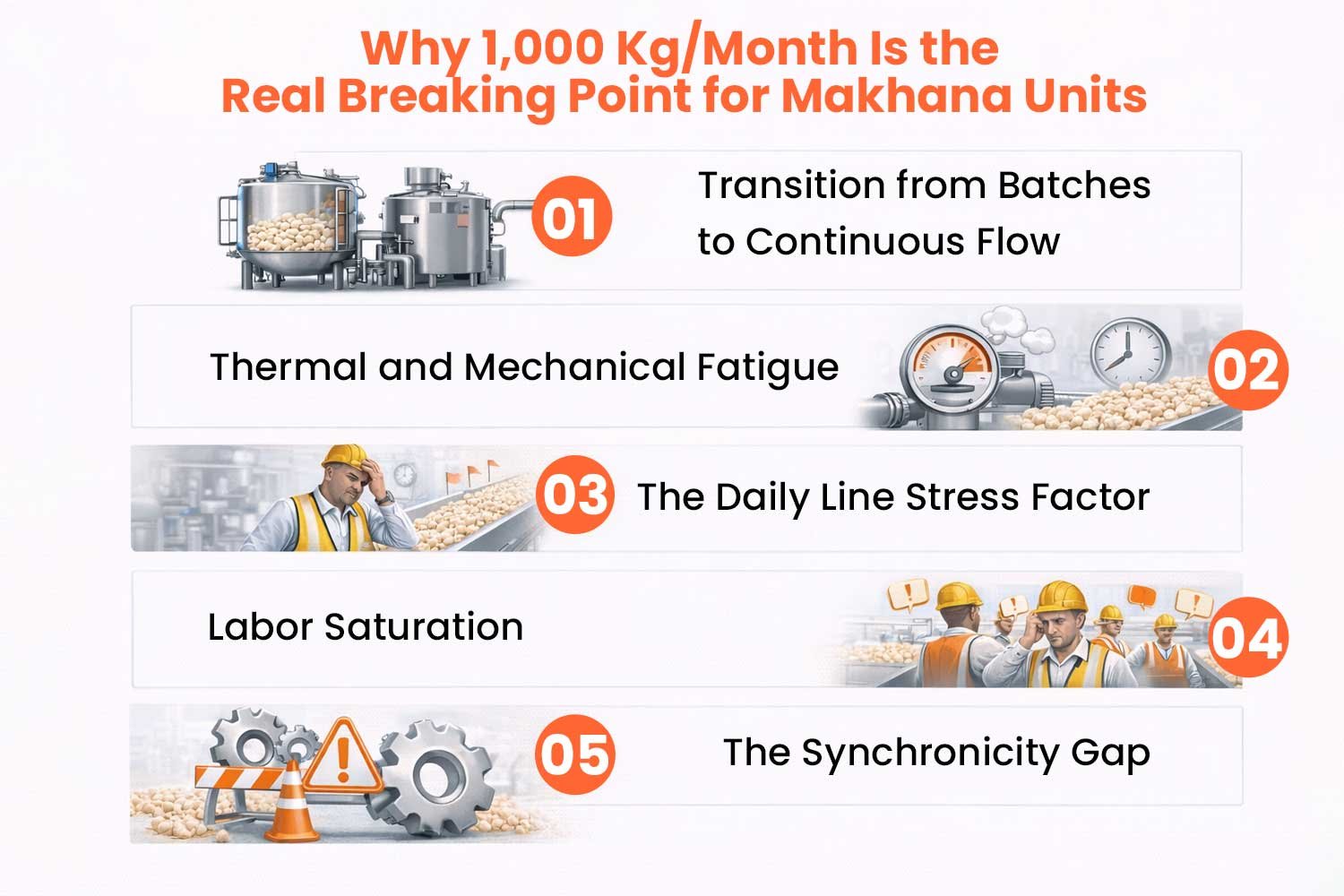

Why 1,000 Kg/Month Is the Real Breaking Point for Makhana Units

- Transition from Batches to Continuous Flow:

At 600 kg, a unit can have down days for maintenance. With a weight of 1000 kg, the operation turns into a never-ending cycle, and even a minimal hour of makhana making machine causes a disturbance in the plan for the whole week due to the accumulation.

- Thermal and Mechanical Fatigue:

The entry-level roasters are mostly made for non-continuous use. The push for a tone per month has metal parts continuously exposed to and alternated with temperatures that are the same as those experienced during the peak periods, leading to thermal fatigue and frequent, unpredictable breakdowns.

- The Daily Line Stress Factor:

While monthly output is a financial metric, daily line stress is the physical reality. It is the point at which manual popping cannot be faster than the mechanised grading, forming physical bottlenecks on the factory floor.

- Labor Saturation:

In small FPOs, the workers are usually doing more than one job. At this level of makhana processing, workers will have to be specialists. If the same person is doing grading, roasting, and packing, context switching happens, which results in a significant decrease in quality and an increase in broken kernels.

- The Synchronicity Gap:

This is where Makhana Machine Capacity Miscalculations become fatal. In a processing plant, there is a difference in speed between the makhana processing machines. For example, a grader that has a capacity of 200 kg/hr is working together with a roaster that processes just 50 kg/hr.

What Starts Breaking First After You Cross 1,000 Kg/Month in Makhana Production

Going over the limit of 1,000 kg/month is the critical zone, where traditional methods turn from being cost-effective to being a liability. If you want to keep profits, you will have to change from human supervision to process-driven engineering.

Why Scaling Fails Without Automation

- Thermal Instability: Small-batch roasters lack the insulation and the exact control required for large-scale production. The temperature changes lead to the uneven expansion of the beans, resulting in a high percentage of rejection and loss of input materials.

- Precision Grading Collapse: Manual sorting cannot guarantee the ±1mm accuracy that is necessary for industrial packing. Inconsistent sizes cause mechanical jams in the automated sealers, which leads to expensive operational downtime.

- Energy Desolation: The heat generated by pushing manual equipment beyond its capacity is so large that it is hard to dissipate. Without integrated heat recovery, your electricity and fuel costs per kilogram rise sharply, taking away your net margins.

- The skill gap bottleneck: At this scale, it is risky to depend on a master roaster’s intuition. PLC-controlled parameters are needed to make sure that batch 100 is exactly like batch 1.

| Operational Pillar | Below 1,000 kg (Manual / Small Batch) | Above 1,000 kg (Industrial Scale) |

|---|---|---|

| Thermal Efficiency | High radiant heat loss; manual flame control. | Integrated heat recovery; PLC-controlled roasting. |

| Grading Precision | Visual sorting, 15% size variance. | Mechanised sieves, <2% variance for export. |

| Labor Dynamics | Skill-dependent (Master Roaster). | Process-dependent (Machine Operator). |

| Waste Recovery | High rejection / broken kernels. | Automated de-shelling, maximised puffing ratio. |

Why Higher Capacity Machines Backfire in Makhana Manufacturing

The majority of failures during makhana machine scale-up can be traced back to a particular machine upgrade, adding one larger roaster to a production line that was changed. Although it seems good in general, it won’t happen right away. When an extensive machine has to be cleaned, graded, cooled, and seasoned by hand or with processes that are too compact, it makes less.

This is precisely where line imbalance kills ROI. The high-capacity roaster makhana machine inflates the volume in bursts, but the rest of the line cannot cope with it. Operators hurry, quality varies, and energy consumption rises without an increase in saleable output that would justify it. The plant will not be able to scale smoothly, but rather get harder to manage.

Mistakes are often made that cause this:

- Roaster with excess capacity: The larger batch size is available, but the handling of feed and discharge has not been improved up to the capacity of the roaster.

- Grading is still done manually: The labour becomes the bottleneck in the production process while the machine is waiting.

- No flow planning for buffer: There is no holding, cooling, or staging area between stages that can handle the rate of output.

The Machine Shift That Actually Works at This Stage of Makhana Processing

When you reach the production level of 1,000 kg/month, your industrial makhana setup will have to undergo a transformation from a minimal assembly of machines to a well-coordinated system. The objective is not only to produce more volume, but also to deliver a 5-star product that will be able to sell at the highest market price.

Modular vs. Full Automation: Making the Choice

- Modular Automation: Instead of an inflexible machine, you are going to install separate automated modules. This gives you the opportunity to increase the capacity of particular sections just as the bottlenecks arise, without having to replace the whole line.

- The Semi-Automatic Limit: Semi-automatic installations are no longer economical if your daily production exceeds 150-200 kg. At this moment, the time wasted in manual loading/unloading, as well as the human error in heat control, is costing more than the machine itself.

- Synchronization > Speed: Even the fastest machines are not worth anything if they are not synchronized. In case your roaster is quicker than your grader, then the kernels will pile up and will probably lose their crispiness. A well-balanced, continuous flow will guarantee that the moisture content is locked in right after popping.

Strategic Setup Checklist

- PLC Control Panels: These are a must for central regulating the temperature and conveyor speed in order to eliminate person-dependent quality.

- Integrated Cooling Conveyors: Moving straight from roasting to cooling cuts down the risk of residual heat creating over-cooked kernels.

- Stainless Steel (SS 304): This is a must for industrial setups that need to comply with FSSAI and export hygiene standards.

How Smart Processors Scale from 1,000 to 3,000 Kg/Month Without Doubling Risk

- Increased processors of a higher caliber should lead the path in the order of flow, not size. The smart processors should be the ones to first stabilize cleaning, grading, and feed consistency before influencing roasting capacity. When input quality is assured, each of the following machines works closer to its maximum output.

- For now, keep the steps that are judgment-heavy manual: Size inspection, final quality checks, and flavour correction are often handled by trained operators at this stage. Full automation adds cost without proportional control benefits.

- Expand in controlled phases: Capacity is increased in 20–30% steps, allowing teams to observe labour load, energy use, and rejection rates before moving further.

- Buffer the process with flexibility instead of just speed: Intermediate holding, cooling, and staging zones absorb variability and prevent upstream or downstream processors.

- Ensure cash flow protection at every stage: Equipment is added only when existing machines are running at stable utilisation, keeping EMIs aligned with real, not theoretical, output.

Conclusion

When the monthly output goes over 1,000kg, makhana machine scale-up is no longer a machine upgrade but a system choice. We designed balanced, scalable setups. At Foodsure Machines, we help our partners make more without giving up control, speed, or profit margins.

FAQ

What is the makhana machine capacity?

It refers to the amount of saleable makhana the machine actually produces per hour, not just the rated number on the spec sheet.

How is the makhana machine capacity calculated?

Start with rated output, then factor in downtime, grading rejects, and real-world inefficiencies seen during daily operations.

Does bigger capacity always mean faster production?

No. Higher capacity only helps if the entire workflow is balanced and downstream processes can keep pace.

Can wrong capacity affect loan repayment?

Yes. Overestimating output can strain cash flow and make EMI payments difficult, even when machines run continuously.

What is the ideal capacity for a small makhana unit?

Aiming for 70–75% of rated capacity keeps production stable, avoids stress on equipment, and supports predictable operations.