Uneven roasting, burnt outer layers, and soft cores are common signs of inconsistent makhana roasting. These defects quietly damage product quality, weaken customer trust, and squeeze margins. In most cases, the issue isn’t raw material, it’s manual or poorly controlled heat. An Automatic Makhana Roasting Machine brings consistency back into the process through controlled, repeatable roasting.

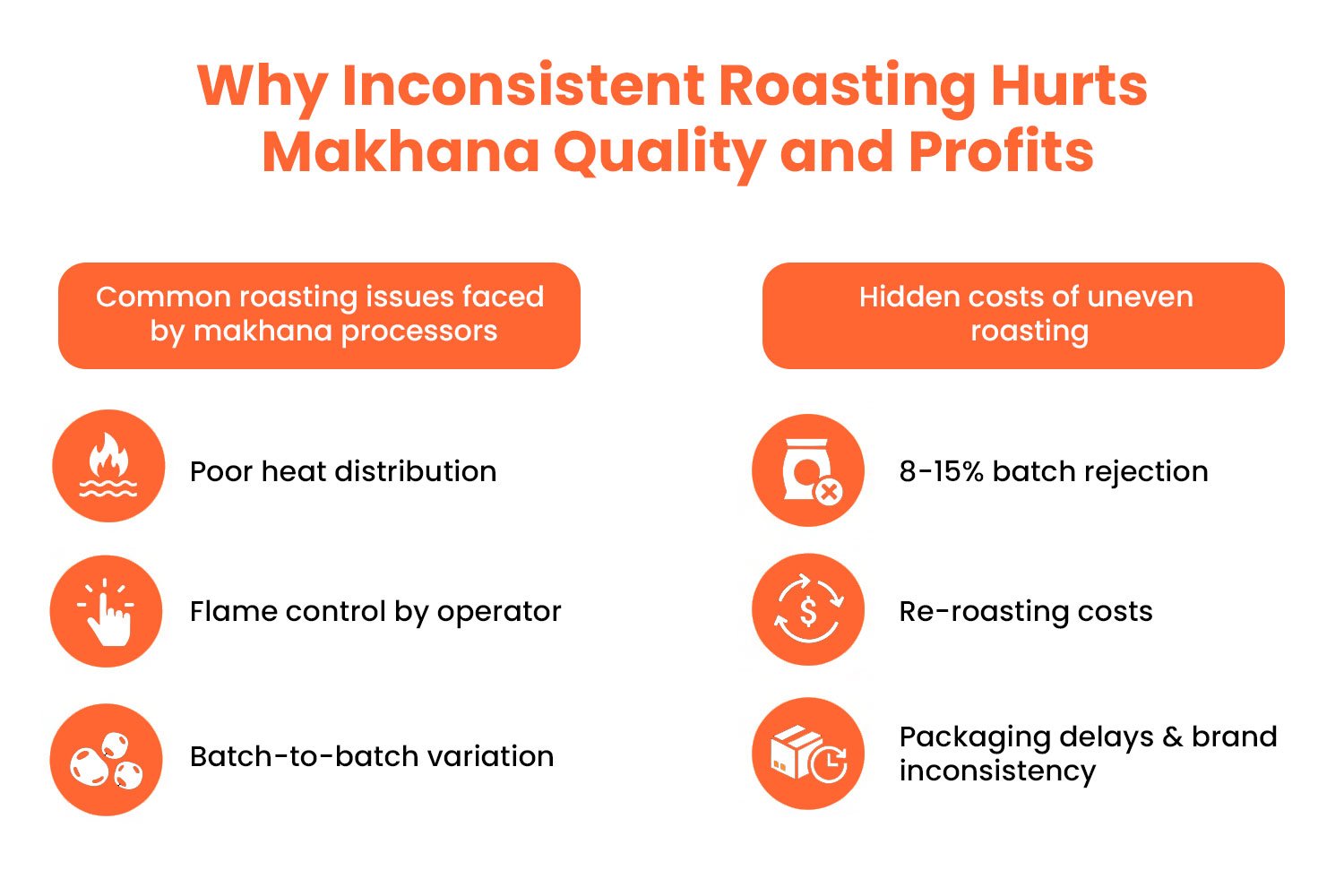

Why Inconsistent Roasting Hurts Makhana Quality and Profits

Roasting inconsistency in makhana processing is not only a quality issue but also a profitability issue. If heat control is done through manual judgment, then the processors would have to deal with poor quality, which would be the output of the entire production. It would gradually lead to high rejection rates, increased operating costs, and loss of brand reliability, especially for those supplying to wholesalers or modern retail outlets.

Common roasting issues faced by makhana processors

- Poor heat distribution: The areas with excessive heat roast the outer layers, while the core remains raw.

- Flame control by operator: The data is not being used by the operators; each operator has their personal way of doing things, which leads to different results from one shift to another.

- Batch-to-batch variation: Same raw material, different output quality, which makes standardisation impossible.

Hidden costs of uneven roasting

- 8-15% batch rejection: Product that cannot be sold because it does not match in texture and colour.

- Re-roasting costs: Additional fuel consumption plus 1-2 extra labour hours per batch.

- Packaging delays & brand inconsistency: Mixed-quality lots slow packing and reduce the likelihood of getting repeat orders.

| Cost Factor | Typical Impact | Estimated Monthly Loss (₹) |

| Batch rejection (8–15%) | 80–150 kg rejected from 1,000 kg input | ₹24,000 – ₹45,000 |

| Extra fuel for re-roasting | 10–18% higher fuel usage | ₹6,000 – ₹10,000 |

| Additional labor time | 20–30 extra hours | ₹4,000 – ₹6,000 |

| Delayed packaging & dispatch | 2–3 day shipment delays | ₹5,000 – ₹8,000 |

| Total hidden monthly loss | — | ₹39,000 – ₹69,000 |

Why Manual and Semi-Automatic Roasting Methods Fail at Scale

The initial phases of testing may require a manual and semi-automatic makhana machine, but these will likely become inadequate as production volume increases. For instance, a small-scale company that utilises an automatic roasted makhana machine can only manufacture a limited number of snacks per day.

Highly skilled Labor is a major factor:

- Over-tasking of the operator: Constant monitoring of the flame by the operator results in slow reaction time, which in turn increases the risk of the product being over-roasted or the quality becoming inconsistent at the end of the shift.

- Variation from one shift to the next: Different operators employ varying methods for heating and timing, resulting in differences in product texture and colour.

No control over temperature and roasting time:

- No repeatability: The Same batch size but different results throughout the process.

- Quality standardisation is challenging: It is impossible to lock the uniform roast profiles for either bulk buyers or retail brands.

Production pressure during peak demand:

- Festival seasons: Sudden 2–3× demand spikes lead to faster roasting, which in turn increases the burn and rejection rates.

- Bulk orders: Manual systems cannot maintain the speed of operations without compromising quality, resulting in late dispatches and client dissatisfaction.

How an Automatic Makhana Roasting Machine Solves These Issues

A fully automatic makhana roasting machine does away with human guesswork completely, simplifies the roasting process, and works under controlled and repeatable parameters. The machine no longer relies on visual cues; instead, it creates constant heat and motion. As a result, every single makhana kernel, even when processed in large quantities, gets the same roasting treatment.

The uniform distribution of heat :

- The heat is controlled in different areas: The heat is distributed evenly throughout the chamber, so there are no hot spots that lead to burnt shells and soft centres.

- A continuous movement system is in place: The Makhana rotates and moves smoothly, which makes it impossible to get overexposed at any point.

Every batch has the same crunch, colour, and taste:

- Roasting parameters are standardised, with time, temperature, and speed maintained at constant levels throughout the batches, resulting in consistent output.

- Quality complaints have been lessened: The distributors and retail buyers are more accepting due to the uniform texture and colour.

Operational cost has been lowered with the higher output:

- Labour has been reduced: Only one operator is needed for the system, thereby reducing dependency on supervision. Reduced while simultaneously increasing

- The usage of fuel/electricity has been optimised: Efficient heat retention results in reduced energy wastage, while simultaneously increasing throughput.

Also read: Top Energy-Efficient Makhana Roasting Machine | Save 40% Energy

Manual vs Automatic Roasting Makhana Machine – A Practical Comparison

| Parameter | Manual Roasting | Automatic Roasting |

| Roasting consistency | Low | High |

| Batch rejection | 10–15% | <2% |

| Labor requirement | High | Low |

| Daily output | Unpredictable | Stable |

| Product quality | Variable | Uniform |

Who Should Invest in an Automatic Makhana Roasting Machine?

An Automatic Makhana Roasting Machine is a worthwhile investment when the manual process starts to limit the growth, quality, or profitability of the business. It is not a matter of replacing human labour, but rather of having a stable production output when the business is scaled up.

- FPOs that have grown beyond a 50 -100 kg/day capacity: As the production scale increases, manual roasting results in more rejections and operator fatigue. The Makhana making machine plays a crucial role in helping FPOs consistently meet the quality and standards required by institutional and bulk buyers.

- Rural entrepreneurs shifting to branded sales: The demands of branded packaging require roasted nuts to have uniform colour, crunch, and shelf stability, areas that manual roasting finds it hard to deliver consistently.

- Units that have had quality complaints or losses repeat: If there are frequent returns, re-roasting, or price negotiations, automation will then directly reduce hidden losses and restore margin control.

Conclusion

Foodsure Machines is all about solving the problem of roasting inconsistency with a dependable automatic makhana roasting machine. Our systems are a great help for processors as they enable them to reduce losses, maintain quality, and confidently scale operations, all without the daily production guesswork.