Due to organised retail and health-conscious consumers, demand for roasted makhana in India is growing rapidly. Most rural companies start with hand roasting to keep expenses low. However, a step rise in demand often brings output, consistency, and profitability to a standstill. This case study shows how moving from a Manual to Automatic Roasted Makhana Machine affected expenses, productivity, quality, and earnings.

Manual Roasted Makhana Production: Small-Scale Makhana Processing Basics

Roasted Makhana is made manually using simple earthen pots or cast-iron skillets for roasting dried seeds on high heat. After that, the seeds are popped manually using mallets. It is a good starting option for those who want to test the market.

- Production Capacity: The production capacity per day is 8-10 kg popped makhana, as the processing needs to be done manually. The average size of each production lot is 1-2 kg roasted, processed in 10-15 minutes at temperatures ranging from 250 to 320°C, taking 2-3 days for tempering. This requires the assistance of 4-6 trained labourer’s.

- Low investment requires only simple equipment such as pots and mallets, which facilitates easy startup by beginners with low investment, generating instant revenues of ₹400-₹450 per kg with losses typically remaining between 20-30%.

Hidden Limitations

- Inconsistent roasting: Uneven heat in manual pans causes imperfect popping, while seconds of delayed malleting lead to burning of seeds.

- Uneven quality: There are substantial losses (loss rate 20-30%) due to sorting and grading by human workers.

- Labour dependency: Requires skilled labour for hot tasks, resulting in high labour costs, labour injuries, and scalability issues.

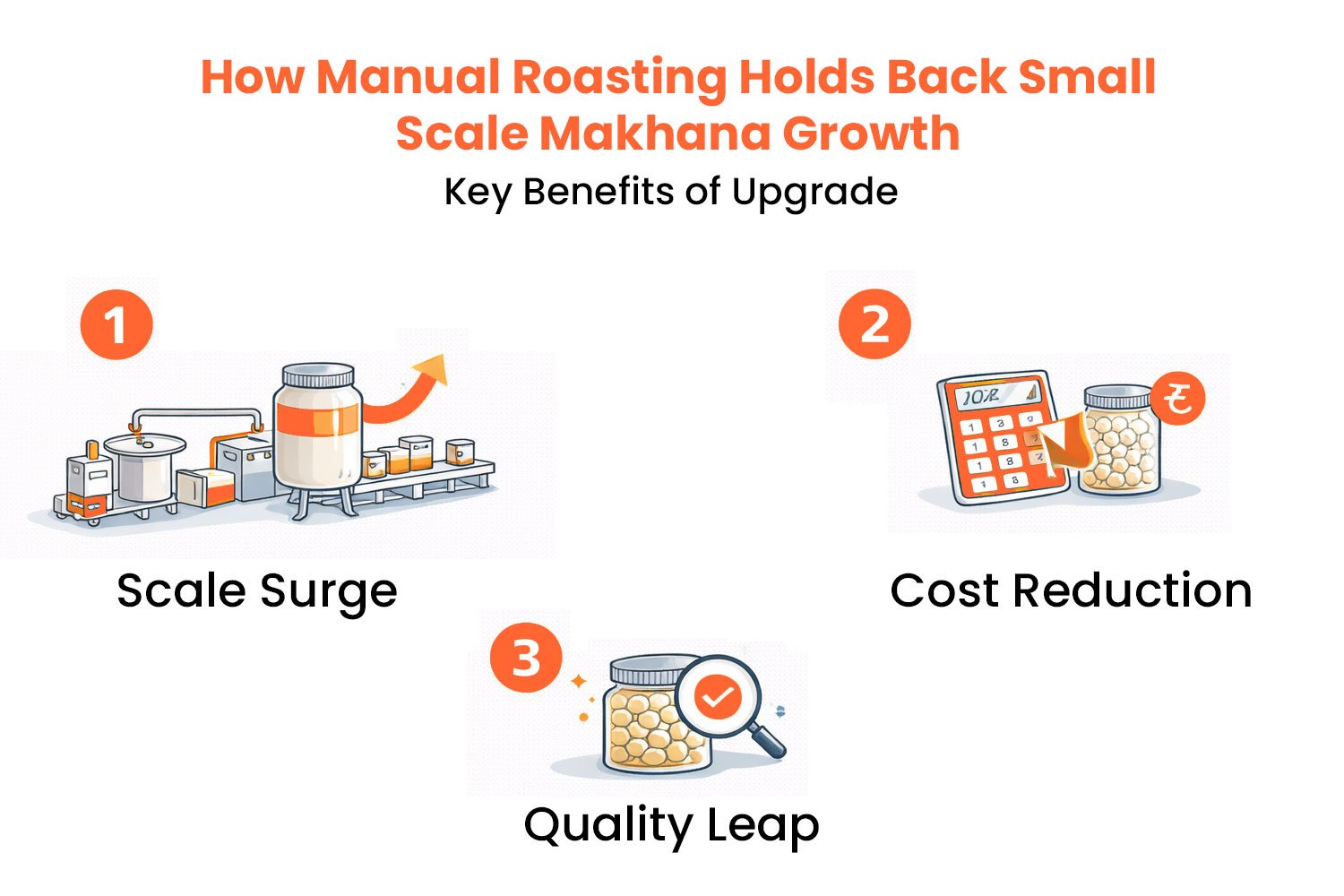

How Manual Roasting Holds Back Small-Scale Makhana Growth

The manual processes compel Makhana Enterprises to implement roasting machines within the next 6-12 months, enhancing production capacity by 5-10 times or up to 50-100kg/day.

Key Benefits of Upgrade

- Scale Surge: Semi-automatic roasters are able to process 5-10 kgs in 8-10 minutes, thus enabling over 40 batches in a day with only two operators.

- Cost Reduction: Fuel costs drop by nearly 50%, and labour costs reduce by around 60%, saving approximately ₹10,000 per month; losses fall to about 5%.

- Quality Leap: Consistent 90% perfect pops, FSSAI compliant for hygiene, premium pricing set at ₹550 per kilo.

Also read: Small Makhana Processing Machine | 5× Faster, High Output

The Decision Point: Why the Startup Chose an Automatic Roasted Makhana Machine

The startup shortlisted the Manual to Automatic Roasted Makhana Machine to overcome the limitations faced by the manual process and aim to produce output between 50-100 kg/day, having eliminated the other option, which was manual.

Evaluation Criteria:

- The requirement of 20-30 kg per hour power capacity could be fulfilled through 3-5 HP single-phase power capacity and 8×10 ft room size.

- The investment will generate returns within 6 to 9 months because projected monthly sales will exceed ₹50,000.

Manual Expansion Rejected:

- The company spends ₹40,000 every month when it hires 8 to 10 employees because there are no procedures for quality control.

- The inconsistency exists because fire outcomes show different results which leads to 25% rejection of results which makes it impossible to establish trust.

- The system can only handle 15 kilograms of material daily while there are unfulfilled wholesale orders.

Dependence on Semi-Automatic Labour:

- The loading process maintains a staff level between 3 and 4 workers who handle mallets while they can only transport 25 kilograms per day because their turnover rate is excessive. The system produces double its normal output although it has 30 percent operational losses.

- The ROI period for the investment now lasts 18 months because the auto industry operates at 90 percent efficiency.

Upgrading to Automatic: Installation & Transition Made Easy

Installation and transition to the automatic roasted makhana machine took only 7-10 days, installing confidence in rural teams at Bihar’s processing hubs.

Setup Timeline

- Makhana making machine installation is done within 2-3 days by technicians, including electric setup and calibration, in order to arrive at a throughput of 20-30 kg/hour.

- Trial runs entailed, in a period of three days, optimisation of sand temperature 250-320°C and batch timing for optimum popping, reaching 90% perfect pops.

- Basic training on the controls, safety, and cleaning, which was purely commonsensical, was imparted within two days, with simple manuals; no advanced skill is required.

Operational Changes

- Manpower reduced: From 4-6 to 1-2 operators, which reduces costs by 60% and handles 50-100 kg/day.

- Smaller cycle times: 8-10 min batches vs. 15 min manual; this enables 40+ shifts without fatigue.

- Predictable quality: Uniform roasting eliminates variations, reducing rejects to 5% for FSSAI compliance.

- Rural workers adapted seamlessly due to intuitive PLC panels with minimal tech, many at only an 8th-grade education level of training, and mastered it in hours.

Results After Switching to an Automatic Roasted Makhana Machine

A Manual to Automatic Roasted Makhana Machine enabled it to increase production scale from 8-10 kg/day to 50-100 kg/day.

Production Output

- Before: Only 8-10 kg per day, with only 4-6 batches.

- After: Peak orders are easily completed at the rate of 50-100 kg per day, without production delays.

Labour and Cost Impact

- Manpower reduced: 4-6 people to 1-2 operators.

- Fuel conservation: 50% through optimal heating of sand, saving ₹5,000/month.

- Per kg control: The cost of production reduced from ₹250 per kg to ₹150 per kg.

Investment Check: Did the Automatic Machine Pay Off?

| Cost/Benefit Type | Details / Estimate | Notes |

| Machine Purchase Cost | ₹2,50,000 – ₹5,00,000 | Depends on capacity (50–150 kg/hour) and automation level |

| Installation & Setup | ₹20,000 – ₹50,000 | Includes onsite setup and minor civil works |

| Training & Labor Adjustment | ₹10,000 – ₹15,000 | One-time training for 2–3 workers to operate efficiently |

| Monthly Electricity / Fuel | ₹5,000 – ₹8,000 | Slightly higher than manual roasting, but more efficient per kg |

| Maintenance & Spare Parts | ₹2,000 – ₹5,000 | Average monthly, depends on machine load |

| Monthly Labour Savings | ₹15,000 – ₹25,000 | Reduced manpower from 4–5 to 1–2 operators |

| Monthly Production Increase | 2–3× current output | From ~50 kg/day → 150 kg/day (approx.) |

| Additional Revenue Potential | ₹60,000 – ₹90,000/month | Based on higher production and better quality |

| Estimated Payback Period | 8–12 months | Includes all setup, training, and operating costs |

Conclusion

We are well aware of the fact that the transition from Manual to Automatic Roasted Makhana Machine is no ordinary step. We at Foodsure Machines perform investment maximisation, production augmentation, and quality enhancement for start-ups and FPOs. Your scale-up will be hassle-free and profitable for you.

FAQ

What does an upgrade from manual makhana roasting mean?

The process of hand roasting needs to change to an automatic system because it will enable you to achieve higher production rates while reducing waste and maintaining identical product quality through every production cycle.

What is the difference in a Manual vs Automatic Makhana Roasting Machine?

Manual roasting depends on the skill of workers and the unpredictable heat distribution of the roasting process, while automatic machines maintain precise temperature control to produce constant high-production output.

When is the right time for an upgrade from manual makhana roasting?

A business will gain considerable scale and increased impetus once demand has crossed between 20 and 25 kg daily, and manual work has ceased to make the grade..

What are the benefits of a Manual to Automatic Roasted Makhana Machine shift?

To accomplish 5-10 times the production, reduce labor charges, and trim away losses to almost 5 percent.

How does a Manual vs Automatic Makhana Roasting Machine impact profits?

Automatic roasting brings two benefits which reduce costs for each kilogram of product and create better product quality. This improvement enables you to sell products at higher prices while increasing your profit margins.

Is a Manual to Automatic Roasted Makhana Machine suitable for small businesses?

The solution serves as a valuable operational tool for both small processors and FPOs who have completed their experimental testing and are prepared to begin their ongoing commercial operations.

When to shift from manual to automatic makhana roasting for better ROI?

Your operations change when you receive frequent bulk orders which lead to delays in manual roasting operations and result in product rejections and lost sales opportunities.

Does an upgrade from manual makhana roasting reduce labour dependency?

Once, such a procedure required from 4 to 6 personnel in order to progress operation. Now, it only needs 1 or 2 expert personnel.

How does a Manual vs Automatic Makhana Roasting Machine affect product quality?

Uniform bursting, cleaner processing, and less burnt or broken products-consistency in popping, can be done by automated machines.

Is the Manual to Automatic Roasted Makhana Machine upgrade worth the investment?

In 8-12 months, the machine will experience self-liquidation with higher efficiency and minimal loss.