Over 60% of mayonnaise batch failures happen after machine installation, not at purchase. Why? Real mayonnaise machine buying criteria aren’t RPM or price, but performance under load. Here’s what engineers check before approval. This blog reveals the five hidden factors that decide texture, stability, and scale before costly production errors occur.

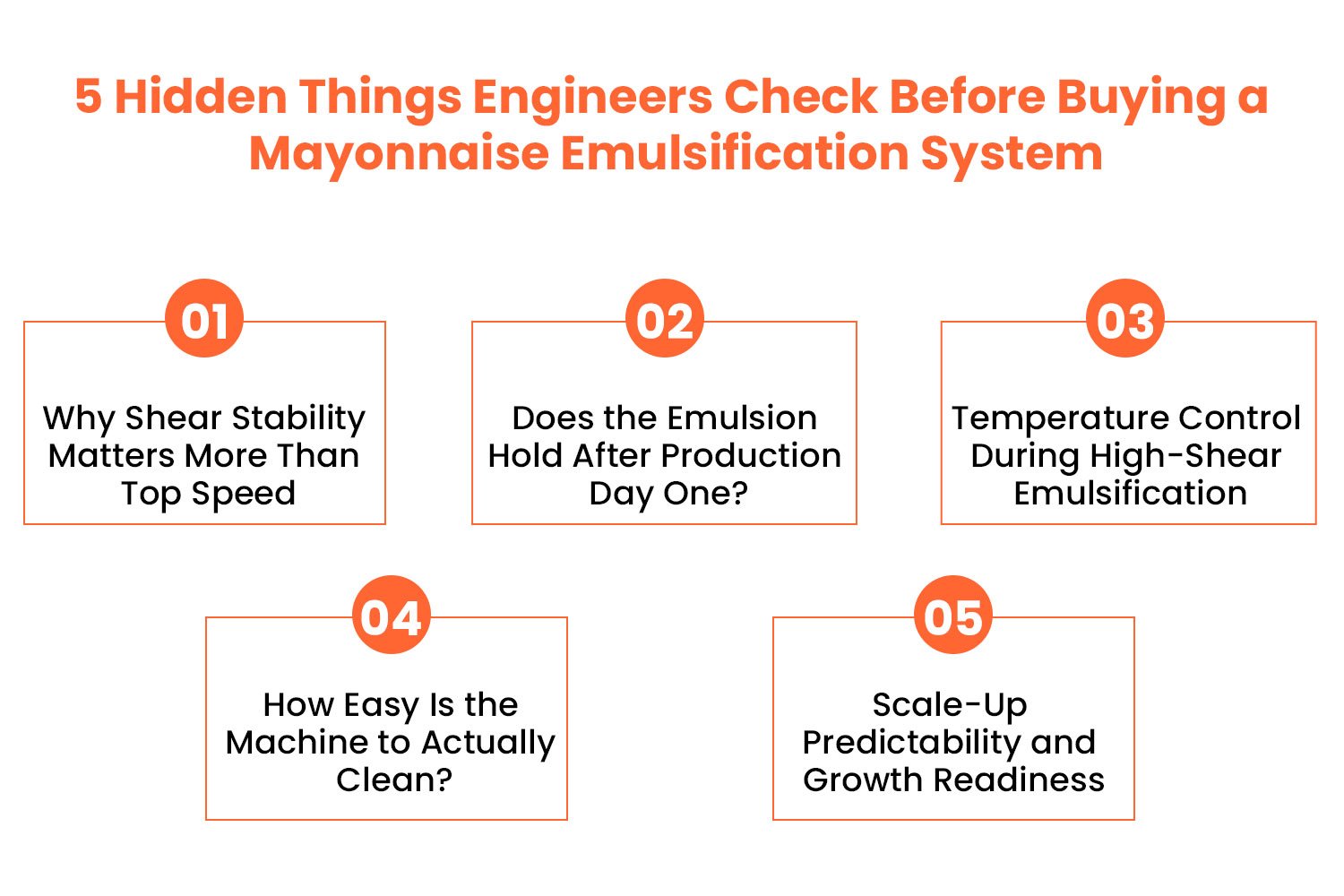

Why Shear Stability Matters More Than Top Speed

Shear performance is probably the most misunderstood mayonnaise making machine purchasing criterion. Several machines brag about high RPM, but engineers decide if the system can keep the shear when the viscosity is going to increase during the oil addition. If the shear decreases in the middle of the batch, the size of the oil droplets increases, and the stability of the emulsion becomes weaker.

Engineers evaluate:

- The shape and the closeness of the gap of rotor-stator.

- Repeatability of shear from various batches.

- Devices that only count on high RPM usually give good results during demos and then crash in actual production.

Does the Emulsion Hold After Production Day One?

Emulsion stability is very important for automatic mayonnaise making machines, as laboratory tests sometimes hide problems that are only revealed in industrial runs. Engineers evaluate by testing:

- Full Oil Loading: Mayonnaise production line handles high oil phases (70–80%) at scale, controlling shear rates to avoid creaming or coalescence at 500–2000 L/h throughput.

- Long Continuous Runs: 8–12hr operations, pump fatigue, and homogeniser endurance test. Viscosity is tracked using Brookfield viscometers (target: <500 cP drop).

- Multiple Back-to-Back Batches: 5–10 cycles without CIP disclose residue buildup, zeta potential (40–60 mV) is used for droplet size uniformity (1–5 μm via laser diffraction).

- 24–72 Hour Storage: Accelerated tests at 40 °C verify phase separation (<2% oil off, top) and creaming index.

The information that goes beyond initial appearance lowers rejection risks by 30–50% in FSSC 22000 compliant plants.

Temperature Control During High-Shear Emulsification

Extreme heat generated by high shear rotors (up to 10,000 rpm) can lead to egg yolk proteins in the mayonnaise being denatured, thus the viscosity drops (20–50 cP/min increase) and the emulsions become unstable. Engineers prioritise machines with precise thermal management for 70–80% oil phases.

- Temperature Rise Rate: The monitoring is done at less than 2 °C/min by PT. 100 probes during phase inversion. Protein coagulation at 55 – 65 °C is a risk that should not be exceeded.

- Jacketed Vessels/Inline Cooling: The double-walled constructions with glycol chillers keep the temperature at 20–40°C, the flow rates of 5–10 L/min prevent the heating of the large 1000–5000 L batches.

- Peak Shear Zone Stability: The inline heat exchangers after the homogenizer stabilize the temperature at less than 45 °C, and the PLC integration logs the profiles for FSSC 22000 audits.

- Long-Term Texture Impact: If the control is poor, there will be syneresis (5–10% serum separation) during the 4-week shelf life, thus the rework will increase by 15–25%.

Validated systems achieved the consistent viscosities of 5000–20,000 cP; the inconsistencies after the launch are greatly reduced.

How Easy Is the Machine to Actually Clean?

CIP (Clean In Place) effectiveness is quite vital for mayonnaise production equipment that processes oil-rich emulsions (70–80%), where residues could lead to the growth of Listeria and flavour transfer. Poorly designed equipment accounts for 20–30% of audit failures under FSSC 22000/BRCGS, with ATP swab levels >100 RLU indicating the presence of potential hazards.

- Dead Zones in Rotor-Stator: Less than 1 mm gaps are checked. CFD modelling of turbulent flow (>2 m/s) helps eliminate 5–10% residue buildup in 3000–10,000 rpm zones.

- Seal Design/Oil Entrapment: EHEDG Type EL Class I mechanical seals with flush ports help to eliminate oil traps. Steam/sanitiser cycles discharge the bioburden <10 CFU/cm.

- CIP Flow Coverage: 360 spray balls + shear component jets accomplish >95% velocity coverage, confirm with riboflavin tests (no shadows post, 20 min cycle at 1.5% NaOH, 60 °C).

- Microbial/Flavour Impact: Insufficient CIP spikes TVC >10^4 CFU/g after 3 cycles, shelf life is reduced by 40%.

Verified CIP shortens the time to production by 25% and also guarantees that there will be no rework.

Scale-Up Predictability and Growth Readiness

Scale-up predictability is a key feature of mayonnaise machines that enables a smooth transition of the process from pilot (500L) to commercial (5000L+) without the breakdown of the emulsion. According to FSSC 22000 case studies, expansion of the process in an unpredictable system results in 40- 60% of the time being wasted due to the system not working properly.

- Droplet Size Consistency: The size of the droplets is kept within the range of 1–5 μm through the continuous application of a constant shear (3000–10,000 rpm), which is done across all volumes. The pilot-to-plant ratio tests (1:10) are used to validate the results obtained by laser diffraction. Coalescence is avoided when the flow rate is >2000 L/h.

- Oil Throughput Without Shear Loss: Large, dose pumps (3 kg/s) are used to maintain 70–80% of the oil phases; the use of modular homogenisers allows for the prevention of the viscosity drop (>20%) by the use of CFD optimised flow paths.

- SKU Flexibility: The rotor quick change and the PLC recipe feature enable switching of vegan/low, fat variants in a time period of <30 min, the scalability of the stator gaps (0.1- 1 mm) ensures that no redesign is necessary.

How the Right Mayonnaise Machine Buying Criteria Prevent Costly Mistakes

Mayonnaise failures become visible after the launch. According to BRCGS audits, 25- 40% batch rejections are due to shear decay after 50 cycles or creaming in 30-day storage. The engineers decide to go for the real-world verification rather than the specification; they guarantee 98% OEE in 5000L+ plants.

- Repeated Runs: Locates residue buildup (>5% flavor carryover) through 100, cycle CIP tests.

- Volume Scaling: Measures droplet uniformity (1–5 μm) at 3x throughput without 15% viscosity loss.

- Storage Cycles: Ensures <2% separation at 40C/72h, avoiding 20% returns.

- Commercial ROI: Along with the time of the downtimes, it is cut by 30%, and the SKUs are scaled seamlessly for FSSC 22000 compliance.

Read More: How to Choose a Mayonnaise Machine That Actually Scales Your Factory – ROI Checklist

Conclusion

At Foodsure Machines, we believe the right mayonnaise machine buying criteria go beyond specifications. We support manufacturers in assessing genuine process performance, scalability, and cleanliness. Our method is aimed at enabling the customer to have continuous stabilisation of the emulsification, foreseeable expansion, and production confidence in the long run, rather than having any kind of surprise after the installation.

Frequently Asked Questions – Mayonnaise Machine Buying Criteria

What are the most important mayonnaise machine buying criteria?

The machine has to deliver consistent shear, control temperature, keep the emulsion stable, be easy to clean, and handle scale-up without failing. Missing any of these, and the batches will suffer.

Is high RPM enough when evaluating a mayonnaise machine?

No. High RPM might look good on paper, but whether it can maintain shear when the batch thickens is what makes the difference between a stable emulsion and separation.

Why is emulsion stability part of mayonnaise machine buying criteria?

Your mayonnaise has to stay uniform over time. If it separates on the shelf, nothing else you did matters.

Does temperature affect mayonnaise texture?

Yes. Too much heat breaks down the egg proteins and alters viscosity, ruining both texture and shelf life.

Why is CIP design a key buying criterion?

A machine that can’t be cleaned properly will trap oil and bacteria, affecting flavor and safety. That’s non-negotiable.

Should scale-up capability be considered?

Absolutely. A machine that works for 50 kg may fail at 500 kg. You need predictable results, no matter the batch size.

Can all machines handle multiple SKUs?

No. Only machines that maintain shear and temperature across recipes can handle multiple SKUs reliably.

Do machine specifications on paper guarantee stability?

No. The specification means very little if the machine doesn’t perform under real production conditions. Trials are what tell the real story.

Is motor size a critical buying criterion?

Not by itself. The motor only matters if it delivers the shear your recipe actually needs. Otherwise, it’s irrelevant.

How can I test my mayonnaise machine buying criteria before purchase?

Run full-batch trials. Monitor shear, temperature, and emulsion stability throughout the run. That’s the only way to know if the machine will work consistently.

Are turnkey systems better for meeting buying criteria?

Often yes. They combine process design with equipment, which reduces guesswork and prevents surprises once production starts.

Who should assess the mayonnaise machine buying criteria?

Usually, a process engineer or an experienced food technologist. They know what to look for and what to test.