More than half of new mayonnaise plants face launch delays due to compliance and formulation errors. The root cause is about choosing between a mayonnaise machine supplier vs turnkey partner blindly. This guide uncovers what really happens between delivery and your first invoice.

What a Mayonnaise Making Machine Supplier Typically Offers

Mayonnaise machine suppliers typically provide core processing equipment, including emulsifiers and mixers. This is different from turnkey suppliers, who take care of the whole plant integration. A mayonnaise making machine supplier is more appropriate for targeted needs rather than comprehensive setups.

Scope of a Mayonnaise Machine Supplier

- Mayonnaise production line suppliers provide high-shear mixers, homogenisers, and storage tanks made of food-grade stainless steel for hygienic production.

- A basic installation comprises on-site assembly, alignment, and initial testing to confirm functionality.

- A small amount of operator training is limited to 1- 2 days of practical machine operation, basic troubleshooting, and safety regulations.

When Choosing a Machine Supplier Makes Sense

- Perfect for 50- 500L R&D batches to test emulsions without the expense of the entire plant.

- In-house formulation teams: Utilise supplier machines for the creation of custom recipes when the experts are in charge of the optimisation.

- Short-term or pilot batches: Suitable for short-term or pilot batches under 1,000 kg/day to test market demand.

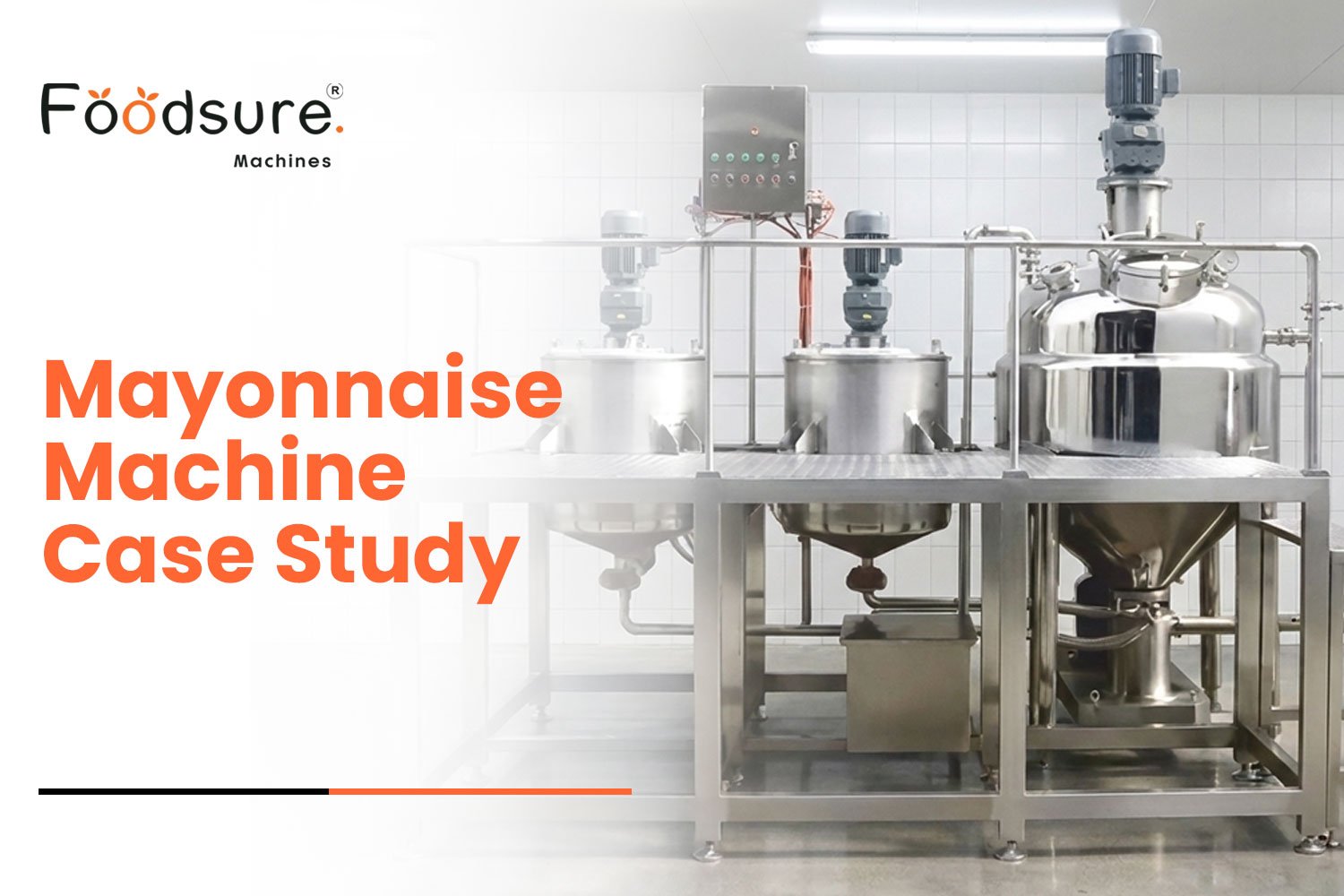

Where Turnkey Support Makes the Biggest Difference

A turnkey manufacturer sees mayonnaise production as a system, rather than just a single machine. Their commitment goes beyond handing over a machine until stable, repeatable output is achieved.

Turnkey Means Owning the Output

The major difference between a mayonnaise machine supplier and a turnkey partner is accountability. A turnkey partner is the one who designs the whole production flow:

- Ingredient dosing and mixing sequence.

- Shear control for stable emulsification.

- Batch consistency across shifts.

- Cleaning in place (CIP) integration.

- Operator, independent process control.

Where Turnkey Adds Long-Term Value

This leads to fewer batch failures during scale-up, a shorter gap between trials and commercial supply, built-in compliance readiness, and lower operator skill dependency.

Mayonnaise Machine Supplier vs Turnkey: Side-by-Side Comparison

| Parameter | Machine Supplier | Turnkey Manufacturer |

| Scope | Equipment only | Complete production system |

| Responsibility | Ends at installation | Ends at stable output |

| Recipe support | Limited | Full process support |

| Scale-up planning | Not included | Built-in |

| Compliance readiness | Partial | Designed into the layout |

| Risk ownership | Manufacturer | Shared with partner |

The Hidden Risks of Choosing Only on Machine Price

Many producers pick a supplier just because the mayonnaise machine equipment offer seems to be more economical. The actual costs become visible later on.

- Common Problems Seen After Installation.

- Oil separation after a few hours or days.

- Inconsistent viscosity between batches.

- The product behaves differently at 300 L vs 50 L.

Such problems hardly ever point to defects in the machinery. These issues usually come from process design gaps, common when the mayonnaise machine supplier vs turnkey decision is made only on upfront cost.

Also read: Mayonnaise Machine Setup Guide: From Delivery To First Batch

How to Choose Between a Mayonnaise Machine Supplier vs Turnkey Setup

The appropriate decision is contingent upon your current situation and your future position within 6 – 12 months.

Decision of Machine Supplier, If:

- You have a mayonnaise formulation that is already validated.

- Your production is in small batches (less than 100 L).

- You have technical staff skilled in emulsions.

- The production is not running at a critical level for the market.

Decision of Turnkey Manufacturer, If:

- You have a plan for commercial or retail sales.

- You want to be sure that the product will be the same from one batch to another.

- You want to go beyond pilot production quickly.

- You want to have a faster commissioning and fewer failures.

Conclusion

At Foodsure Machines, we not only supply equipment but also become partners in your production. Our complete solution guarantees that your mayonnaise line will be able to deliver a consistent output, performance that can be easily scaled, and lower failure rates. We help manufacturers decide what the best configuration is from the very first day, definitely not after problems have arisen.

Frequently Asked Questions – Mayonnaise Machine Supplier vs Turnkey

What is the real difference between a mayonnaise machine supplier vs turnkey?

A mayonnaise machine supplier sells equipment, while turnkey means someone is accountable for working production.

Which option suits first-time mayonnaise manufacturers better?

In a mayonnaise machine supplier vs turnkey choice, turnkey reduces early mistakes for first-time manufacturers.

Is a turnkey more expensive than buying from a supplier?

On paper, maybe, but in a mayonnaise machine supplier vs turnkey comparison, turnkey usually costs less after rework and failures.

Who handles product consistency in a turnkey setup?

In a mayonnaise machine supplier vs turnkey model, turnkey partners own consistency, not just installation.

Can I start with a supplier and scale later?

You can, but mayonnaise machine supplier vs turnkey decisions made early affect how painful scaling becomes.

Which option helps prevent oil separation?

When comparing a mayonnaise machine supplier vs a turnkey setup, turnkey setups handle emulsification control far better.

Does a machine supplier help with formulation?

Usually, no, which is one of the biggest gaps in mayonnaise machine supplier vs turnkey setups.

Who manages food safety and compliance in turnkey projects?

In a mayonnaise machine supplier vs turnkey setup, turnkey partners design compliance into the process.

Is turnkey only for large factories?

No. In a mayonnaise machine supplier vs turnkey decision, size matters less than production goals.

What breaks most often with machine-only purchases?

Process stability fails first in the mayonnaise machine supplier vs turnkey choices focused only on machines.

Which option gets products to market faster?

Turnkey wins in most mayonnaise machine supplier vs turnkey comparisons because fewer trials are needed.

How should I decide between a supplier and a turnkey?

In a mayonnaise machine supplier vs turnkey decision, choose based on risk, not price.