Nearly 40% of energy bar profits are lost due to inefficient production line design. Rising raw material prices, labour shortages, and outdated workflows silently eat into margins for growing energy bar manufacturers. What starts as a low-cost setup often turns into high wastage, inconsistent output, and rising operational stress as volumes increase.

This guide explains how manufacturers cut production costs by 30–40% by redesigning their energy bar production line. You’ll see actual cost ranges, automation choices, and capacity trade-offs so you can decide what makes financial sense before investing further.

Small-Scale vs Industrial Energy Bar Production Line: Cost Comparison

| Cost & Feature Category | Small-Scale Energy Bar Production Line | Industrial Energy Bar Production Line |

|---|---|---|

| Production Capacity | 50 – 200 kg/hr (Startup / Pilot) | 500 – 2,000+ kg/hr (Industrial) |

| Automation Level | Semi-automatic, operator-assisted | Fully automated PLC & HMI controlled |

| Mixing System | Planetary / ribbon mixer | High-torque continuous industrial mixer |

| Mixer Cost | ₹3 – 8 Lakh | ₹25 – 60 Lakh |

| Ingredient Dosing | Basic load-cell or semi-manual | Automated multi-ingredient dosing |

| Forming & Cutting | Semi-auto slab former & cutter | High-speed automatic former with guillotine |

| Forming & Cutting Cost | ₹6 – 12 Lakh | ₹40 – 90 Lakh |

| Cooling System | Short conveyor or static cooling | Multi-zone industrial cooling tunnel |

| Cooling Equipment Cost | ₹4 – 8 Lakh | ₹35 – 70 Lakh |

| Optional Enrobing | Tabletop unit (optional) | Full-width continuous enrober |

| Enrobing Cost | ₹6 – 10 Lakh | ₹50 Lakh – ₹1.2 Cr |

| Packaging Type | Semi-automatic flow wrapper | High-speed servo flow wrap line |

| Packaging Machine Cost | ₹10 – 18 Lakh | ₹60 Lakh – ₹1.5 Cr |

| Quality Control | Manual inspection & basic testing | Inline metal detector & check-weigher |

| QC Equipment Cost | ₹2 – 4 Lakh | ₹20 – 50 Lakh |

| Labour per Shift | 6 – 10 operators | 2 – 4 operators |

| Total Line Investment | ₹35 – 80 Lakh | ₹3.5 – 8 Crore |

| Best For | Startups, D2C brands, pilot batches | FMCG brands, export & contract manufacturing |

What’s Driving High Energy Bar Manufacturing Plant Cost in Growing Factories

Founded on a small scale of operation, many small businesses produce their own energy bars line using less expensive manual or semi-automated equipment. This keeps initial costs low for the owner (the entrepreneur), but it can also create additional unknown control costs in future years as your volume grows. The most important issues facing small energy bar producers include:

- Inconsistent mixing can lead to loss of some batches.

- A high reliance on human labour for the forming, cutting, and handling of energy bars.

- The manual movement of raw materials can lead to more waste in each batch of production.

- Bottlenecks can develop between the mixing, cooling, and packing processes.

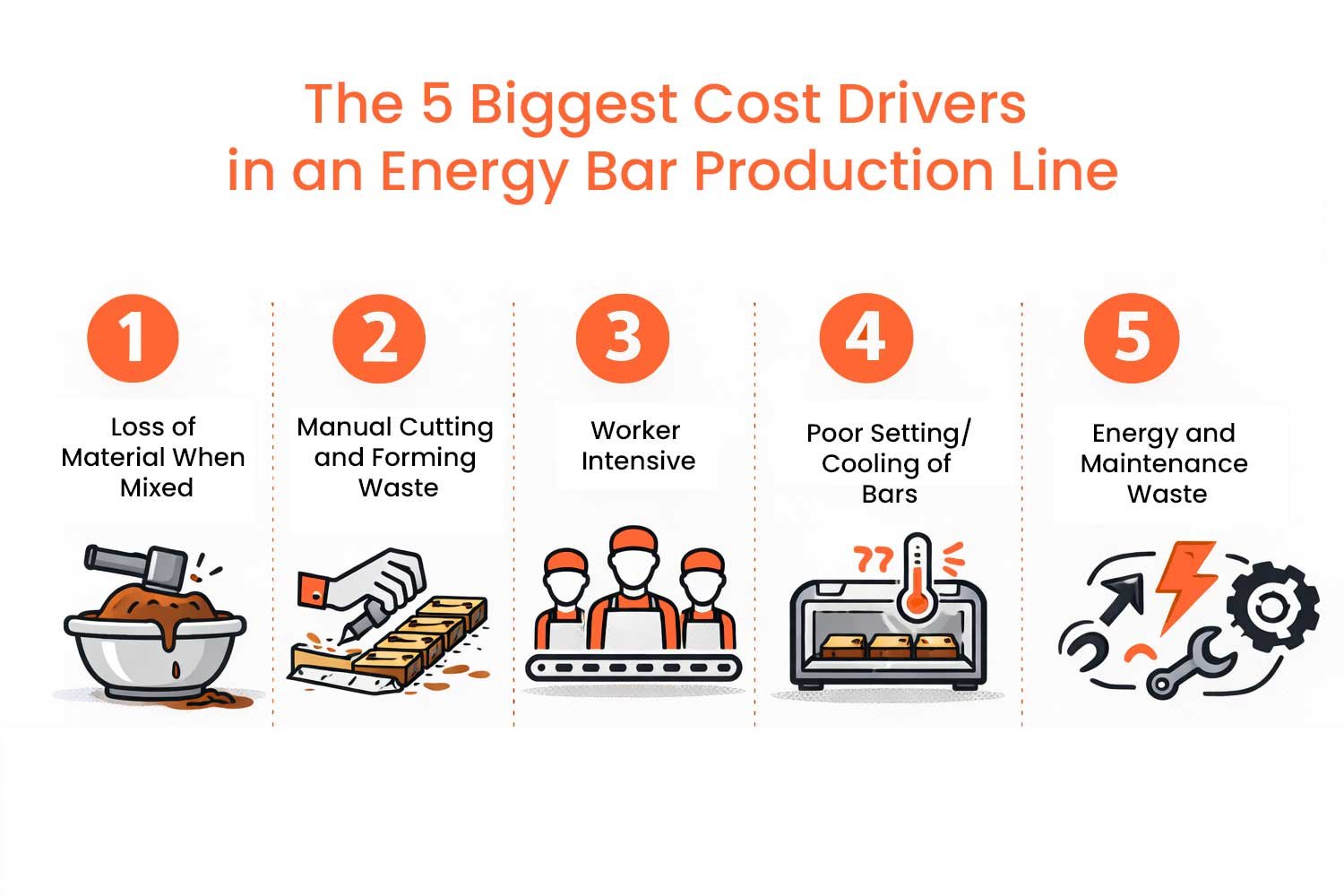

The 5 Biggest Cost Drivers in an Energy Bar Production Line

Understanding where costs originate is the first step toward reducing them.

- Loss of Material When Mixed: User error with mixers, whether it is with improper technique when using a machine or mixing by hand without adequate experience, will cause uneven or too much contamination in the product. When you look at getting a 2-3% loss per batch is what you have at the end of the month, that number will begin to build.

- Manual Cutting and Forming Waste: Manual forming of the bars alone can yield different weights for each bar, resulting in: Overweight bars (loss of material). Underweight bars (loss of quality).

- Worker Intensive: The majority of smaller operations have a minimum of 8-12 workers per shift solely to form, handle, and align the materials. The cost of each of these people will increase yearly; however, the amount of output remains static.

- Poor Setting/Cooling of Bars: If bars are improperly set or cooled, they will become warped, bent, or stuck at the time of packing. This will lead to downtime during the packing process.

- Energy and Maintenance Waste: Motor sizes that are larger than what is needed, poor insulation, and unplanned and frequent maintenance will cause higher energy costs and unscheduled interruptions of production.

Automation Strategies That Cut Energy Bar Manufacturing Costs by 40%

The smartest way to energy bar machine your work process is to make sure that you identify and automate the right stages of your process so that you do not have to spend a lot of money on bar processing line to achieve good results.

Continuous Mixer vs Batch Mixer: Using a continuous mixer allows you to produce a product that has a consistent appearance and texture, taste, and has the added benefit of lower raw material loss and fewer operators needed to run the machine. $5 to $7 per 100 lbs of labor and raw material costs saved.

Automatic Bar Forming and Cutting: With a servo-controlled bar forming and cutting machine, you will automate the processes of bar forming and cutting, with the benefits of:

- A consistent weight for each bar was produced.

- Less waste of materials in cutting.

- An increase in production rate (more bars produced / hour)

- $10 to $15 per 100 lbs on raw material and reject costs saved.

Inline Cooling System: A patented inline cooling system stabilizes the product before packaging, resulting in lower product breakage and lower production downtime costs. Less time lost due to product breakage and less time spent repacking products due to the inline cooling system.

One Operator Model Production Line: With a well-designed automatic energy bar production line, you will have only 2-3 operators to operate the line, vs 8-10 on a traditional energy bar production machines. Therefore, you will save 12-18% on your labor expense each year.

Real-World Example: 500 kg/day Unit That Reduced Costs by 38%

An average-sized nutritional product company that manufactures protein and energy bars had been impacted by increased labour costs resulting in inconsistently weighted bars. With the installation of an automated bar forming, cutting, and heating/cooling system:

- Labor Reduced: The number of labourers decreased from nine personnel working per shift to three personnel.

- Raw material loss changed from a 5% – 1.8% rate.

- Overall output consistency improved dramatically.

Ultimately resulted in a manufacturing cost savings of thirty-eight percent (38%) per product produced in less than fourteen months of operation.

Conclusion

Reducing energy bar packing line factory is not about buying the most expensive equipment. It is about controlling waste, improving consistency, and designing a production line that matches your real output needs. Manufacturers who redesign their energy bar production line typically recover their investment within 12–18 months through lower material loss, reduced labour dependency, and smoother production flow.

At Foodsure Machines, we help manufacturers plan and implement energy bar production lines that balance automation, cost, and scalability. Our focus is on building systems that support long-term growth without locking businesses into unnecessary capital expenses.

If you are evaluating your next production upgrade or planning a new setup, getting clarity before investing can save years of margin loss. Request a consultation to understand what configuration makes sense for your production goals.

FAQs

Who are the best energy bar production line manufacturers in India?

Leading manufacturers include Foodsure Machines, Kanchan Metals, and other India-based food processing equipment suppliers.

What equipment is needed for a small-scale energy bar production line?

A basic setup includes a mixer, bar forming and cutting machine, cooling conveyor, and a simple packaging machine.

How much does an energy bar production line cost in India?

Costs typically start around ₹35 lakh for small lines and can reach ₹8 crore for fully automated industrial facilities.

Is a turnkey energy bar production line suitable for startups?

Yes. Turnkey lines help startups avoid setup mistakes and begin production faster with controlled investment.

How do I choose the right energy bar production line for my business?

Selection should be based on daily output targets, automation level, budget, and future expansion plans.

Are automated energy bar forming machines available in India?

Yes. Many Indian manufacturers supply fully automated bar forming and cutting machines.

What is the capacity of a typical energy bar production line?

Capacities usually range from 50 kg/hour for small units to over 2,000 kg/hour for large industrial plants.

Can one production line handle different energy bar recipes?

Yes. Adjustable molds and controls allow multiple bar sizes and formulations on the same production line.

What hygiene standards are required for energy bar production?

Food-grade stainless steel construction and FSSAI-compliant machine design are essential.

How long does it take to install an energy bar production line?

Most energy bar production lines are installed and production-ready within 2–4 weeks.