The protein bar sector is growing in India. A growing number of people are choosing nutritious portable snacks, and manufacturers are scrambling to keep up with this demand. But, starting or expanding capacity isn’t as easy as just buying the machine. The best protein bar machine in 2026 can make your process more efficient, safer, and more consistent, while providing consistency across your bars in taste and quality. Selecting the wrong equipment can lead to delays, increased costs, and a lot of variability in products.

How to Identify the Best Protein Bar Machine in 2026

Understanding your production objectives is the first step to selecting the best protein bar machine in 2026. Are you deciding if you are going to operate in a high-volume environment or small batch production runs? There are distinctions in these machines’ automation, capacity, and speed. Look for features like:

- Stainless steel construction for sanitary conditions

- Easy maintenance and cleaning

- Variable speeds and mixing options

- Energy efficient

- Support and training from the manufacturer

Having properly installed or the training included in your investment reduces operational risk and saves you critical time.

Choosing the Right Machine Size and Capacity Matters

When purchasing the best protein bar machine in 2026, picking the right size and capacity is important. Making the wrong decision could limit production, increase waste, or even add expenses. Start by checking your projected requirements of daily production. Are you looking to produce a few hundred bars a day or thousands for retail and exporting?

Think about these considerations:

-

- Daily Production Needs: It is important to identify how many bars you want to produce each day. This allows you to consider the machine’s size and speed.

- Space Considerations: A large machine requires more space on the floor. Before investing in a large machine, ask if your factory has enough area to operate without it impacting production.

- Level of Automation: Depending on the type of machine you use will determine your staffing levels. Semi-automatic equipment will require more staff, and fully automatic machines can handle larger volumes.

- Scalability: It is wise to buy a machine that can grow with your business. A machine with a modular design will allow you to add capacity down the road.

- Energy Efficiency: Larger equipment may be more efficient. It’s good practice to figure out your energy costs to avoid any negative surprises.

When you have purchased equipment for snack and health bar production that is sized correctly and at the appropriate capacity, it can help your operation run effectively, support product quality, and improve your return on investment!

Key Features of Protein Bar Production Equipment

The most important considerations for protein bar production equipment should be efficiency, safety, and reliability. Consider the following when analyzing machines:

- Uniform mixing and consistent distribution of ingredients

- Consistent form and portion size

- Emergency shutoffs and other safety devices

- Support for multiple recipes for versatility

- simple to use control panels

Keep in mind that a decent machine is not only about speed; it also consistently makes bars of the highest quality while ensuring the safety of your employees.

Choosing Industrial Protein Bar Machinery for Factories

High-volume production is the goal of industrial protein bar machinery. These machines typically include:

- conveyor systems that facilitate efficiency

- automated cutting and mixing functions

- Mechanisms that reduce human interaction to maintain cleanliness

Important considerations before buying industrial machinery:

- Installation space needs

- Using energy wisely to save costs

- Availability of replacement components

- ease of upkeep and cleaning

Buying the right equipment now can help avoid problems later and keep your business running smoothly as it grows

Read More: What Is A Protein Premix Machine and How Does It Support Innovation In Food Processing

Understanding the Protein Bar Production Line Process

The various processes involved in a full protein bar production line include mixing, molding, baking or setting, cooling, and packing. The machines that carry out these functions are:

- Reduces manual input

- Maintains hygienic practices

- Boosts productivity

- Maintains consistent product quality

Think about the flow when planning your production line. A machine that fits well into your line will reduce errors, save time, and increase productivity.

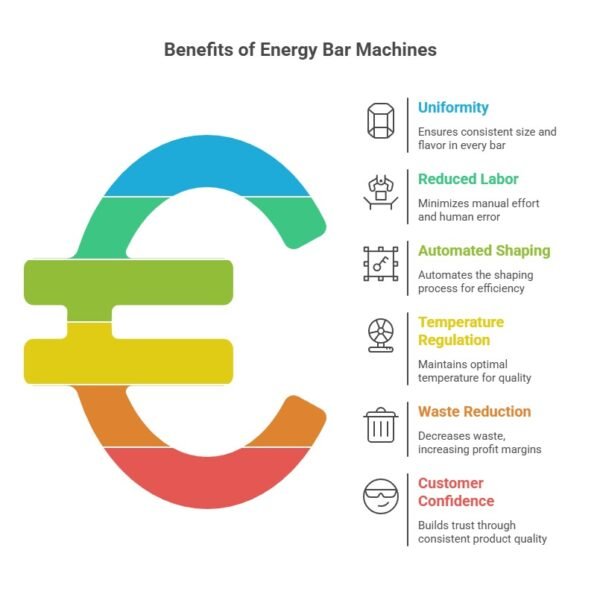

Advantages of Using an Energy Bar Making Machine

Protein bar manufacturing machine that produce energy bars increase production speed and reduce variability. The benefits include:

- Every bar is uniform in size and flavor

- Reduces manual labor and human error

- Automated shaping and temperature regulation

- Less waste increases profit margin

When you are dealing with multiple customers, consistency in every bar creates confidence and leads to repeat customer orders.

Read More: Everything You Need to Know About Protein Bar Machines

Tips for Choosing Food Processing Equipment for Bars

When selecting food processing equipment for a bar, you need to keep in mind a number of factors regarding hygiene, durability, and efficiency. Here are some factors to take into account:

- Wherever possible, opt for stainless steel to maximize safety.

- Investigate how easy aides are to clean and maintain.

- Assess energy efficiency to reduce operating costs.

- Confirm the availability of spare parts.

- Check for manufacturer support and give after-sales service.

An understanding of your production needs and marrying bar production machines with the right support will help guarantee everything runs smoothly day-to-day.

How to Plan for Machine Maintenance and Longevity

No matter how a best protein bar packaging machine is, it will wear down eventually. If maintained correctly to prolong the life of the machine, you can help keep the machine performing well.

- Daily cleaning and sanitizing.

- Regular visual inspections of belts, motors, and blades

- Lubrication of parts that move

- Ongoing scheduled maintenance is done by a qualified professional

- Always keep a few spare parts on hand for your machine

So having a safety maintenance plan in place will help stop delays, reduce repair costs, and keep the production line running.

Budgeting and ROI for Protein Bar Machines

Investing in the best protein bar machine in 2026 is not simply purchasing equipment—it is purchasing a business decision. Here are some things to consider when calculating ROI:

- Estimate production/output capability daily and potential revenue from the bars produced

- Costs of setup, training, and maintenance

- Energy and labor savings from either a hands-on approach or an outdated machine

- Durability of the machine and his long it will last

Having a strategic budget will ensure you purchase the protein bar manufacturing equipment that pay you back quickly, help with production, and ultimately lead to a better product.

Boost Production with the Best Protein Bar Machine

Selecting the best protein bar equipment in 2026 is all about finding a balance between efficiency, quality, and support. Foodsure Machines gives you high-quality, durable, and easy-to-use equipment, and also includes installation, training, and it has 24/7 support. Invest today and increase your production, make the same bars each time, and grow your business with confidence.

🚀 Grow Your business with confidence!

Have questions or need support? Connect with us instantly.

FAQs

Q1. What is the best protein bar machine in 2026 for small businesses?

For small-scale production, machines that are less in capacity, simple to operate, and easy to clean are optimal.

Q2. Will industrial protein bar machinery allow for multiple recipes?

Yes, almost all machines will accommodate varying ingredient substitutions and bar size.

Q3. How do I maintain protein bar production equipment?

Maintaining machinery running efficiently and smoothly requires frequent cleaning, lubrication, and prompt replacement of worn-out components.

Q4. Is an energy bar-making machine necessary to invest in?

Yes, it takes the manual labor out of the end product, increases the production capability, and allows for consistent product quality.

Q5. What should I check for before purchasing food processing equipment for bars?

Build quality, compliance with hygiene, ease of maintenance, energy efficiency, and support direct from the manufacturer.

Q6. What formula does ROI calculate for protein bar machines?

Estimate production, revenue potential, and savings of energy and labor. Do not forget to include repairs and maintenance, plus the added years of service of your machine.

Q7. What is the demand for the best protein bar machine in 2026?

Demand is high due to booming functional-food manufacturing and small-batch automation.

Q8. What is the future of protein bar machines?

The future is fully automated, AI-controlled, and capable of multi-texture bar production.

Q9. Who made the first modern automated protein bar machine?

Early versions were pioneered by industrial food-processing manufacturers in the 1990s.

Q10. What type of protein bar machine is most profitable?

Fully automatic high-capacity extruders deliver the best profitability.

Q11. Is a 30% profit margin too high for a protein bar machine business?

No—30% is normal for specialized food-production equipment.

Q12. What is the “50 rule” for choosing a protein bar machine?

Buy a machine that can produce 50% more than your current demand to scale safely.