In the makhana industry, scaling up is necessary. As market demand for makhana increases across India and abroad, food manufacturers still relying on semi-automatic makhana machines face challenges in increasing makhana production to meet the growing demand. Recent industry studies show that a fully automatic makhana line is resulting in 3x increased output and 40% reduced labour costs.

In this guide, we will take you through the benefits of upgrading to a fully automatic Makhana line, how to increase Makhana production with automation, Makhana production automation for higher ROI, and how Foodsure Machines‘ fully automatic Makhana line can boost your output by 3x.

What Is A Fully Automatic Makhana Line?

A fully automatic makhana line is a complete setup of integrated machines made to carry out the complete process of Makhana production, from raw seeds cleaning to grading, roasting, puffing, polishing, flavouring, and packaging, without manual intervention.

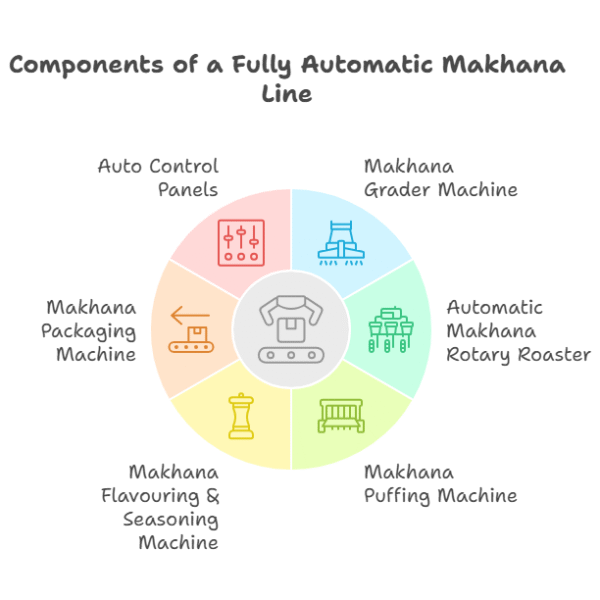

The fully automatic makhana line includes:

- Makhana Grader Machine

- Automatic Makhana Rotary Roaster

- Makhana Puffing Machine

- Makhana Flavouring & Seasoning Machine

- Makhana Packaging Machine

- Auto control panels

Benefits Of Upgrading To A Fully Automatic Makhana Line

➨ Increased Production Capacity: Automated makhana lines can operate continuously, processing large batches with minimal downtime. This directly increases your output, often by up to 3x compared to traditional manual setups.

➨ Improved Product Hygiene: With reduced human contact, the makhana processing line meets FSSAI and export hygiene standards, ensuring safer, cleaner, and contamination-free products.

➨ Better ROI: Though the initial investment is higher for a fully automatic makhana line, savings on labor, reduced wastage, and increased production allow most makhana businesses to recover costs within 12–18 months.

➨ Reduced operational errors: Auto control panels regulate temperature, timing, and flow of makhana, reducing the chances of manual labour mistakes like over-roasting or uneven puffing.

➨ Scability: A fully automatic makhana line is made to scale up your business. You can increase capacity by simply adding more units or upgrading individual machines, without interrupting existing operations.

But how do all these benefits come together in day-to-day makhana factory operations? It starts with the right industrial Makhana processing machines built for scale and performance.

Makhana Processing Machine For Large-Scale Manufacturing

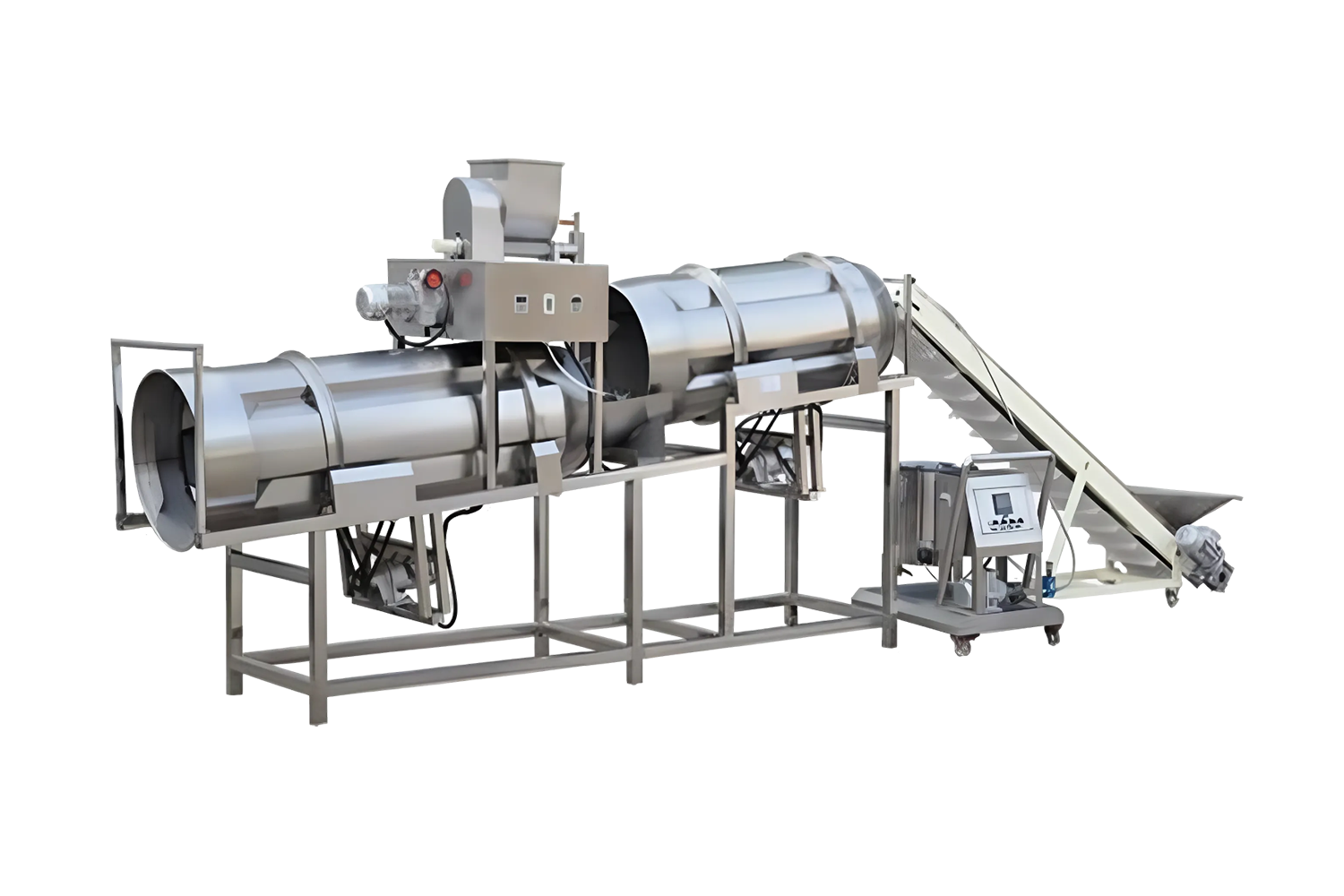

A Makhana processing machine is the backbone of industrial manufacturing. Our heavy-duty stainless-steel machines can handle tasks such as:

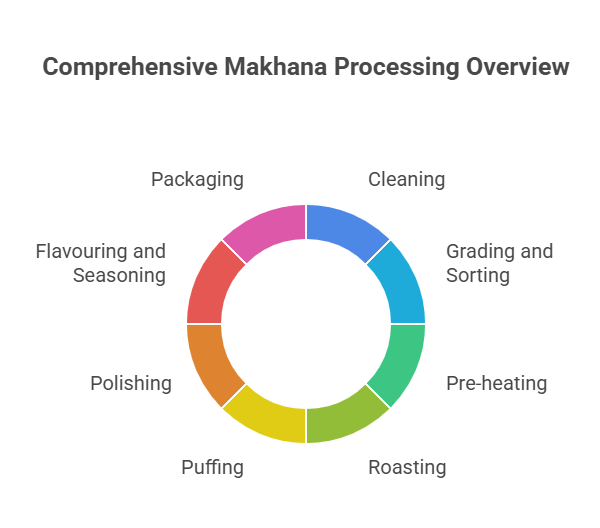

⮞ Cleaning

⮞ Grading and sorting

⮞ Pre-heating

⮞ Roasting

⮞ Puffing

⮞ Polishing

⮞ Flavouring and seasoning

⮞ Makhana packaging machine

Each makhana automatic machine is built with food-grade material and made to handle continuous operation, so investing in a fully automatic makhana line for commercial use can help you increase your output by 3x.

Read More: From Manual To Modern: How Advanced Makhana Processing Machines Transform The Industry?

Fully Automatic Makhana Line

For large-scale Makhana businesses, investing in a fully automatic Makhana line for commercial use is important. These commercial-grade setups are built to handle high volumes, maintain product consistency, and meet strict quality standards required by retail chains and international buyers.

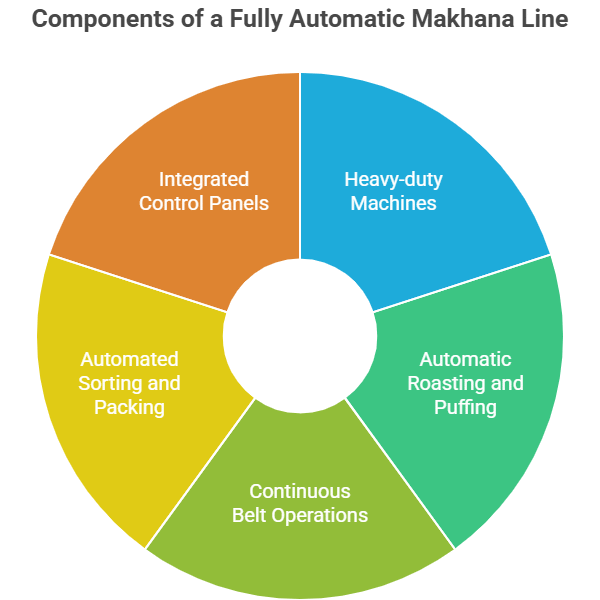

We offer industrial-grade Makhana lines equipped with:

➨ Heavy-duty Makhana processing machines

➨ Automatic roasting and puffing machines with digital controls

➨ Continuous belt-driven operations for non-stop production

➨ Automated sorting, polishing, and packing units

➨ Integrated control panels with temperature and speed regulation

Made for makhana processing factory doing large-scale production, these lines help manufacturers meet rising market demands without compromising on efficiency, hygiene, or product quality. But how does automation boost Makhana output and efficiency? Let’s understand this now.

How To Increase Makhana Production With Automation?

Start with designing your factory space for the movement of materials, from raw makhana to the final packed product. A good production layout guarantees that each fox nut processing machine connects easily, reducing delays and extra handling.

Install the right machines for each stage

To fully automate makhana production, you’ll need the right makhana machines in your factory:

- Cleaning and Grading machine– removes dust, stones, and sorts by size

- Pre-heating machine– prepares seeds for uniform roasting

- Automatic makhana roasting machine– gives even roasting with precise temperature control.

- Makhana Puffing machine– adds the crunch with fast, consistent puffing.

- Polishing machine– removes the outer skin and improves shine

- Seasoning and flavouring machine– add masala or flavours like achari lemon, peri peri, chocolate, cheese & jalapeno, indian masala, tandoori, and more automatically.

- Packaging machine– packs makhana quickly with minimal manpower.

➨ Add automation control panels: Automation levels are the most important point of your makhana production line. They allow control of critical settings like roasting temperature, puffing time, conveyor speed, and moisture levels, all from a central unit. These panels help reduce human error, ensure product consistency, and make the entire process easier to manage.

➨Integrate machines for smooth operations: To achieve smooth, uninterrupted production, it’s essential to connect each machine in the line with conveyors. This ensures that Makhana moves efficiently from one stage to the next, without any delays. By integrating all the machines, you create a fully automatic Makhana line that operates continuously, improving speed, consistency, and overall efficiency.

➨ Monitor performance and optimize production: Once your automated Makhana line is running, it’s time to track its performance. Our advanced display controls allow you to monitor critical parameters like roasting time, puffing consistency, and moisture levels, helping you fine-tune settings for optimal output.

➨ Scale operations to meet growing demand: As your business expands and demand increases, our systems are made to scale makhana production with ease. Instead of overhauling your entire setup, you can add new machines or upgrade existing ones to increase capacity.

Read More: Green Energy, Cleaner Makhana: Solar-Powered Roasting Lines in Far-Flung Villages

Contact Foodsure Machines

Call, email, or request a quote from Foodsure Machines. We’re here to support your food processing machine requirements.

Why Choose Foodsure Machines For Fully Automatic Makhana Line?

➨ High-quality and durable engineering: Our fully automatic production line are manufactured using top-grade materials and advanced technology, ensuring long-lasting performance with less maintenance to increase the makhana processing.

➨ Strong after-sales support and service: We don’t just sell machines – we build relationships. Our expert team is always ready to provide installation, training, and technical support to keep your operations running smoothly.

➨ Energy-Efficient & Cost-Effective: Save on makhana processing plant cost with our energy-efficient machines that are built to deliver maximum output with minimal power usage.

➨ Serving Pan India & Beyond: With successful installations across India and growing international demand, Foodsure Machines, the makhana machinery manufacturer, is a name trusted by food entrepreneurs and manufacturers alike.

➨ Trusted Name in Food Processing Machinery: Foodsure Machines, the best automatic Makhana line manufacturers in India, has built a strong reputation in the industry for delivering high-performance and reliable food processing equipment modified to modern manufacturing needs.

Ready To Upgrade A Fully Automatic Line To Boost Your Output By 3x?

With advanced solutions from Foodsure Machines, you can increase the production of your Makhana business by 3x. Our proven expertise, customizable equipment, and dedicated support make us the ideal partner for your automation journey. Contact us at +919870533566

FAQ

Q1.What is a Fully Automatic Makhana Line?

It is a complete automated system for roasting, grading, peeling, and packing makhana.

Q2. Who should invest in a fully automatic makhana line?

Large processors, FPOs, and export-focused food manufacturers.

Q3. What is the production capacity of a fully automatic makhana line?

It typically ranges from 80 kg/hr to 500 kg/hr depending on the model.

Q4. How much space is required for installation?

Usually 1,200 to 3,000 sq. ft. depending on layout and output.

Q5. Does it reduce labor cost?

Yes, it cuts manpower by up to 70% compared to manual processing.

Q6. What operations are fully automated?

Roasting, cracking, peeling, grading, polishing, and packing.

Q7. Is a fully automatic makhana line energy efficient?

Yes, modern systems are designed for low power and fuel consumption.

Q8. Can it produce export-quality makhana?

Yes, it ensures uniform size, color, and food-grade hygiene standards.

Q9. How long does installation take?

Installation usually takes 7 to 15 working days.

Q10. What is the average ROI period?

Most buyers recover their investment within 12–24 months.

Q11. Is customization available in fully automatic makhana lines?

Yes, capacity and layout can be customized as per production needs.

Q12. What is the price range of a fully automatic makhana line?

Prices generally start from ₹25–30 lakh and increase with capacity.