High diesel prices and wasteful fuel use have eaten into profits for rural makhana units for years. Here’s the thing: energy-efficient makhana roasting machines are changing that. Solar-powered models and low-consumption units now offer real savings, better heat control, and more consistent roasting. FPOs and small processors are finally seeing better returns without the fuel burden. What this really means is lower costs, higher quality, and a clear path to sustainable growth.

The Problem With Traditional Roasting Setups

Here’s why traditional makhana roasting setups are falling short:

- They burn through firewood or diesel fast. Fuel costs pile up quickly, especially in rural units where every rupee counts.

- Most of them are fuel-hungry and waste energy. You end up spending more than you earn.

- Roasting is hit-or-miss. Some batches come out right, others don’t. That inconsistency hurts both quality and pricing.

- The entire process demands constant manual work. It’s slow, tiring, and not scalable.

- Cleanliness is an afterthought. These units rarely meet basic food safety standards, which makes it harder to sell to bigger buyers or scale up into new markets.

What Makes a Roasting Machine Energy-Efficient?

Power bills high? Roasting uneven? Machine stalling during outages? Here’s what a smart, fuel-saving top solar roasting machine manufacturer actually looks like and why it pays off.

Fuel Efficiency

Energy-efficient makhana roasting machines are set up to cut down fuel use without compromising output. They use smart heating systems like hot air or drum roasting that run well on lower power. Insulation and heat recovery tech keep the temperature stable, so the top solar roasting machine manufacturer holds its efficiency even when power inputs drop. Less energy wasted means lower costs per batch, simple as that.

Uniform Heating

Consistent roasting isn’t optional; it’s what separates good makhana from wasted stock. These best energy-efficient food processing machine handle that with rotating drums or conveyor setups that make sure every seed gets even heat. You set the temperature, walk away, and get a uniform batch from start to finish. That level of control means fewer burnt batches and better profits.

Solar or Hybrid Options

Some models go a step further with solar or hybrid energy setups. That’s especially useful in areas where power cuts slow production. These best energy-efficient food processing makhana machine can switch between solar and grid or diesel as needed, cutting your energy bills and keeping the line moving. For rural units, this is how you stay productive without depending entirely on expensive or unreliable sources.

Real Savings: A Case from Bihar’s Madhubani District

A Farmer Producer Organization in Madhubani, Bihar, was burning cash on fuel and still getting uneven roasting results. So they switched to a solar-powered, energy-efficient makhana roasting machine. The result? A 60% drop in fuel costs saves them over ₹40,000 every month. Roasting is now consistent, cleaner, and easier to sell. This one affordable solar-powered roasting unit didn’t just lower their bills; it raised their product quality and made the business more sustainable. That’s what smart upgrades look like.

Makhana Roasting Machine Price & Specification Breakdown

Let’s break it down. This isn’t just about switching to solar, it’s about real monthly savings, more consistent roasting, and fewer headaches with fuel. Let’s see what that looks like when you put the numbers on the table.

| Parameter | Details |

|---|---|

| Roasting Capacity | 50–60 kg/hour |

| Fuel Type | Hybrid (LPG + Solar) |

| Power Consumption | 1.5–2 kW |

| Fuel Savings | 60% compared to traditional roasting |

| Monthly Cost Savings | ₹35,000 – ₹45,000 |

| Build Material | Food-grade Stainless Steel (SS304) |

| Machine Cost (with Solar) | ₹3.5 – ₹4.5 lakh |

| Payback Period | 8–10 months |

| Government Subsidy | Up to 60% (FME / Solar schemes) |

For a full guide on how leading processors in Rajkot are upgrading with hybrid roasting lines, read this case-based breakdown.

Financing and Government Support for Energy-Efficient Equipment

-

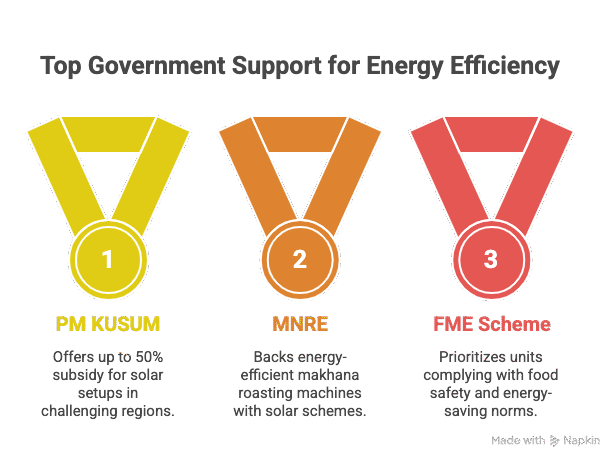

Government Support Is Real

-

Solar Machines Get Preference

-

- If your affordable solar-powered roasting unit runs on solar or hybrid, you are already one step closer to approval.

- MNRE has relaxed rules around solar panel efficiency for rural units. That makes these machines cheaper and easier to adopt.

-

Loans Are Tied to Modernization

- Under the FME scheme, units that comply with food safety and energy-saving norms stand a better chance.

- Bihar and Madhya Pradesh offer specific support like feeder-level solarisation and state subsidies to make these upgrades more accessible.

Want to know which subsidy fits your unit best? Explore Government Support for Solar Food Processing

Why Energy-Efficient Makhana Roasting Machines Make Sense for Rural Units

- Lower fuel costs, even off-grid: Advanced insulation and controlled heating cut diesel or electricity use. Many solar roaster dealers in India run on solar or hybrid power, so you are covered even with an unreliable supply.

- Consistent roasting, better quality: Automated temperature controls ensure even roasting across every batch. No more burnt edges or raw centers, just uniform, sellable output.

- Made for rural use: These solar roaster dealers in India use food-grade stainless steel and require minimal upkeep. They are made for real-world conditions, not factory floors.

- Easy to run, no training hassle: User-friendly interfaces mean semi-skilled operators can handle them without needing constant support and expensive training.

Why Foodsure Machines Leads in Solar Roasting

Foodsure Machines helps FPOs and rural units set up the right-sized makhana roasting line, with no waste, no overspend. Our energy-efficient roasting machine for makhana handles up to 100 kg/hour with precise temperature control (100°C–450°C) and a SS 304 hygiene-grade build. Batch or continuous roasting, consistent quality, and flavoring-ready. It’s a clean, scalable system that saves energy and boosts profits from day one. Ready to install a solar roasting unit that actually pays for itself?

FAQ

1. How do solar-powered roasting lines benefit rural makhana processors economically and environmentally?

They cut fuel costs simply as that. Once the makhana machine is installed, solar systems use free energy, not diesel, which adds up to big savings over time. On the environmental side, you are not burning fossil fuels, which means lower carbon output and a cleaner setup that rural communities can be proud of.

2. What are the key challenges to implementing solar-powered makhana roasting machines in remote villages?

Cost is the first hurdle. Then there’s the need for basic electrical infrastructure and people who know how to run and maintain the system. But these aren’t dealbreakers. With the right government support, like subsidies and local training programs, these challenges can be handled.

3. How does using solar energy improve the hygiene and quality of roasted makhana compared to traditional methods?

You get steady, controllable heat with solar-powered machines, which means every batch gets roasted evenly. No more guesswork or burnt spots. That consistency helps meet food safety standards and keeps quality high, something diesel-fired bhattis often fail to do.

4. Is the makhana business profitable with an Energy-Efficient Makhana Roasting Machine?

Yes, because the machine cuts energy costs and boosts output, increasing profit margins.

5. Which is better for production, roasted makhana made in an Energy-Efficient Roasting Machine or normal raw makhana?

Roasted makhana made in the machine sells better due to consistent texture and higher market demand.

6. How to store machine-roasted makhana for a long time?

Store it in airtight, moisture-free containers to maintain crispiness and freshness.

7. Can I eat machine-roasted makhana daily?

Yes, machine-roasted makhana is a healthy low-fat snack suitable for daily consumption.

8. What is the shelf life of makhana roasted in an Energy-Efficient Makhana Roasting Machine?

Properly packed roasted makhana lasts 6–9 months.

9. How many minutes should I roast makhana in the Energy-Efficient Roasting Machine?

It typically takes 5–8 minutes depending on batch size and desired crunch.

10. What is the healthiest way to eat makhana roasted in this machine?

The healthiest way is plain or lightly seasoned roasted makhana without added oil.

11. Why is makhana not crispy even after using the roasting machine?

Insufficient roasting time or moisture exposure after roasting can reduce crispiness.

12. How much protein is in 1 cup of makhana roasted using this machine?

One cup of roasted makhana contains around 5–6 grams of protein.