In just 45 days, one snack brand turned around its packaging problems and unlocked modern retail orders. The team wasn’t struggling with demand; they were losing out because of leaks, short shelf life, and missing batch codes. So they invested ₹5.5 lakh in a packaging machine for startup with nitrogen flushing. That one decision changed everything. Shelf life jumped. Returns dropped. Retailers who once said no started placing trial orders. It was the food packaging machine for small business that finally matched the product quality.

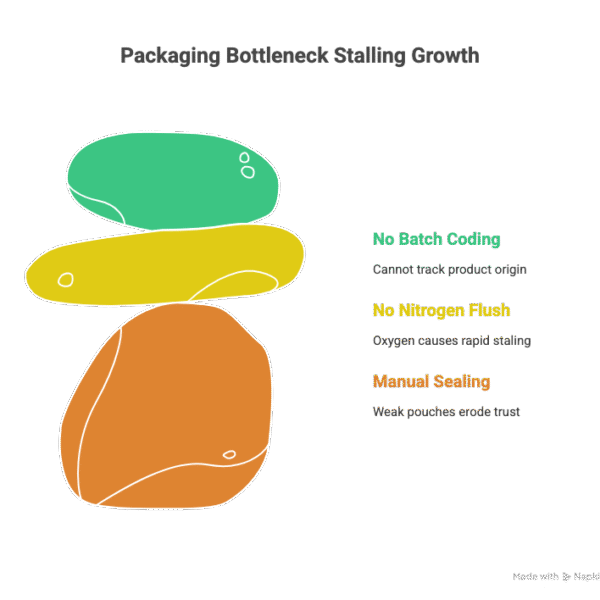

Old Packing, New Problems: What’s Stopping Your Growth

Here’s the thing: the product was solid, but the makhana machine packaging wasn’t pulling its weight. And the market noticed.

-

Manual sealing caused trust issues

The team was sealing by hand, which meant weak, uneven pouches. Some leaked, some just looked sloppy. That’s a big red flag for retailers. If it doesn’t look clean and reliable, they will not stock it, no matter how good it tastes.

-

No nitrogen flush, no shelf life

Oxygen stayed trapped inside every pouch. That sped up staling and caused the bags to puff. Distributors started seeing stale stock. A full 17% of what went out was coming back. You can’t scale with that kind of loss.

-

No batch coding, no entry to modern trade

There was no way to track when or where a batch was packed. That’s a non-starter for big retailers. Compliance needs traceability. Without coding, the product never made it past the first pitch.

The fallout?

- ₹2.3 lakh in the finished product was rejected outright.

- 3 major retail deals gone.

- 17% of stock returned, unopened, due to bloated pouches.

What this really means is: they didn’t have a product issue. They had a packaging bottleneck, and it was blocking growth at every level. Once they fixed that, the rest of the business could finally move forward.

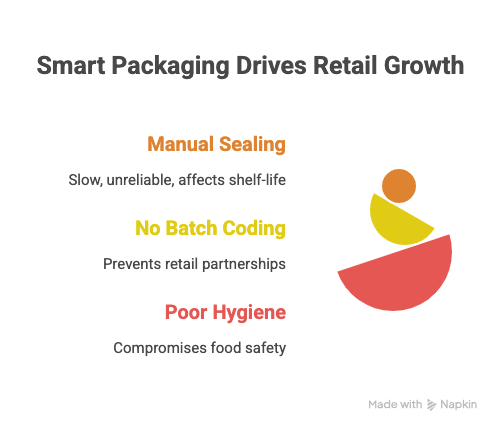

How a Smart Packaging Bet Unlocked Retail Growth

Most food-packaging machine for small business don’t fail because the product isn’t good. They fail because the packaging can’t keep up. So they made one clear decision: fix the weakest link. Not with a massive factory overhaul. Just a smart, focused investment in a proper packaging machine for startup. And once that small scale vacuum packing machine was in place, everything shifted. Here’s how that single move unlocked growth:

- Vacuum + Nitrogen Flush Packaging Machine For Startup (around ₹5.5 lakh): We moved on from hand-sealing. This food packaging machine for small business packs up to 60 pouches per minute, gives reliable leak-proof seals, and keeps our product fresh by flushing out oxygen. It fixed our biggest shelf-life and quality issues in one step.

- Batch Coding Unit (approx ₹25,000): Retailers want traceability. Without batch codes, we weren’t even considered. This food-grade vacuum sealing machine add-on unlocked access to organized retail and helped us tick all the compliance boxes.

- SS304 Hygienic Contact Parts: Every part that touches food is stainless steel, food-grade SS304. It’s non-negotiable for hygiene, and we didn’t cut corners.

- Delivery and Training (around ₹18,000): Our team handled everything delivery, installation and full staff training. We were up and running in 15-20days.

- Other Costs: GST and packaging materials weren’t included, and they vary by region and suppliers. But the core small scale vacuum packing machine gave us what we needed to stop losing money and start scaling.

What This Really Meant for the Business

- We stopped bleeding money on spoiled stock.

- Returns dropped, shelf life improved, and every pouch looked consistent and retail-ready.

- Modern trade buyers finally took us seriously. We weren’t blocked at the packaging gate anymore.

- Instead of apologizing for our finishing or shelf life, we could focus on growing the brand.

45 Days to Retail-Ready Packs and Fewer Returns

It took 45 days. Once the right packaging machine for startup was in place, things moved fast. Quality shot up. Complaints dropped off. Retailers stopped hesitating, and buyers started coming back. Let’s break it down with real numbers:

| Metric | Before | After |

|---|---|---|

| Shelf life | 30–40 days | 90+ days |

| Output | 250–300 pouches/hr | 3,600 pouches/hr |

| Labour | 3 people | 1 operator |

| Complaints | Frequent | Near zero |

| Cost per pouch | ₹3.12 | ₹2.73 |

| Returns/losses | ₹18,000/month | ₹1,500/month |

| Distributor reorder rate | 62% | 91% |

| Monthly revenue | ₹1.4 lakh | ₹3.2 lakh (in 3 months) |

Speed, Shelf Life, and Sales: Why the Right Machine Changed Everything

- Built for Hand-Packing Units: Ideal for small to mid-sized brands, makhana machine, peanuts, chana, or foxnuts by hand. It helps move from basic sealing to automated packaging without over-investing.

- Affordable Nitrogen Flushing: Adds nitrogen flushing essential for long shelf life and freshness at a price much lower than the ₹10–15 lakh industrial setups. That means protection from spoilage without overspending.

- Meets Retail & Export Standards: Includes batch coding and food-grade vacuum sealing machine hygiene to help you meet modern trade and export compliance, with no more disqualifications over packaging.

- Solves Common Packaging Problems: Say goodbye to weak seals, puffed pouches, and high return rates. This packaging machine for startup improves consistency and shelf appeal without increasing your team size

Foodsure Machines

Our team at Foodsure Machines stepped in with a ₹5.5 lakh vacuum and nitrogen flush packaging machine for startup that did 60 pouches a minute. We didn’t just drop off the machine; we installed it, trained their team, and made sure it was compliant and clean. That single move fixed returns, improved shelf life, and gave the startup the packaging standards big retailers actually expect.

Ready to Make Your Product Retail-Ready?

Contact Foodsure Machines at your convenience via phone or email.

FAQ

1. How did the ₹5.5 lakh packaging machine solve the startup’s key challenges?

It replaced hand-sealing with automated vacuum and nitrogen flush packaging. That stopped leaks, cut down returns, and gave the product a longer shelf life. Adding a batch coder meant each pouch met traceability norms, no more rejections from retailers.

2. Why is compliance with packaging regulations critical for FMCG retail entry?

Without proper batch codes, labels, or food-grade packaging, most retail chains won’t even consider your product. Meeting FSSAI and Legal Metrology standards isn’t an option; it’s the price of entry.

3. What role did Foodsure Machines play in enabling retail access?

They didn’t just sell a machine. They handled setup, trained the team, added coding, and ensured the entire system met retail-grade hygiene standards. That’s what opened the door to modern trade.

4. Are packaging machines profitable for a startup?

Yes, efficient machines reduce labor costs and boost production margins.

5. What is the price range of a makhana packing machine for startups?

Typically ₹2–8 lakh depending on speed and automation.

6. Is starting a cardboard-box packaging unit profitable with machines?

Yes, high demand from e-commerce makes it consistently profitable.

7. What are the disadvantages of using fully automatic packaging machines?

Higher upfront cost, skilled maintenance, and limited flexibility.

8. How many bags can a startup-friendly packaging machine produce per minute?

Usually 30–120 bags per minute based on model.

9. What is the cost of a sachet packaging machine in India for new businesses?

Around ₹1–5 lakh depending on features.

10. What is the typical lifespan of a pouch packing machine for startups?

About 7–12 years with proper maintenance.

11. How can a startup begin a food packaging business using machines?

Choose your product, get licenses, buy the right machine, and set up quality processes.

12. Which type of machine is best for packing products in a new startup?

Form-fill-seal (FFS) machines are the most versatile for beginners.