Small makhana units often struggle with uneven flavoring. Hand-coating leads to broken pieces, wasted seasoning, and batches that just don’t taste the same. That kind of inconsistency turns off retailers and limits how far you can grow with a manual coating. A semi-automatic makhana flavoring machine for small business can change that completely. It controls seasoning flow, drum speed, and batch size so every batch comes out evenly coated, with less waste and less labor. You get better flavor, better margins, and a product that earns retailer trust. For a small processor, it’s a big step toward making your makhana ready for serious retail.

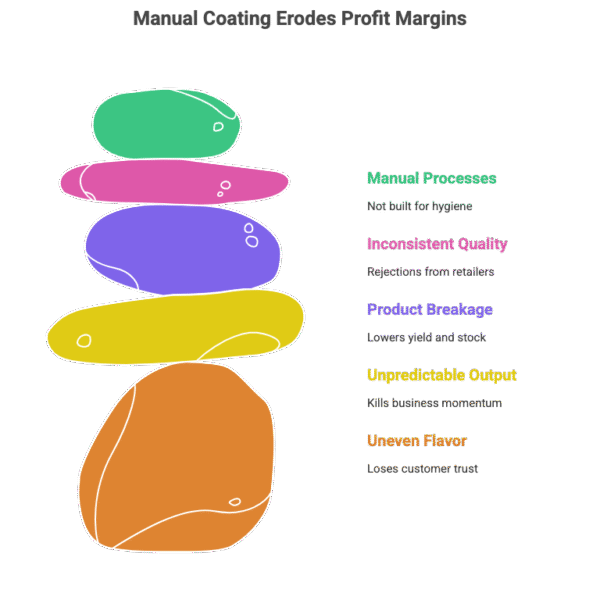

Is Manual Coating Silently Killing Your Profit Margins?

- Uneven flavor loses customers: If it doesn’t taste the same every time, buyers stop trusting your brand.

- Manual labor creates unpredictable output: Some batches come out okay, others do not. That kind of unpredictability kills your momentum.

- Hand tossing breaks the product: Broken makhana means lower yield and less sellable stock.

- Inconsistent quality leads to rejections: Retailers and export buyers won’t risk shelf space on unreliable batches.

- Manual processes: They are not built for hygiene or growth. And you can’t scale something that doesn’t meet basic retail standards.

Read more: Makhana Processing Machines For Sorting, Roasting & Packing

What Changed When We Switched to Semi-Automatic Coating

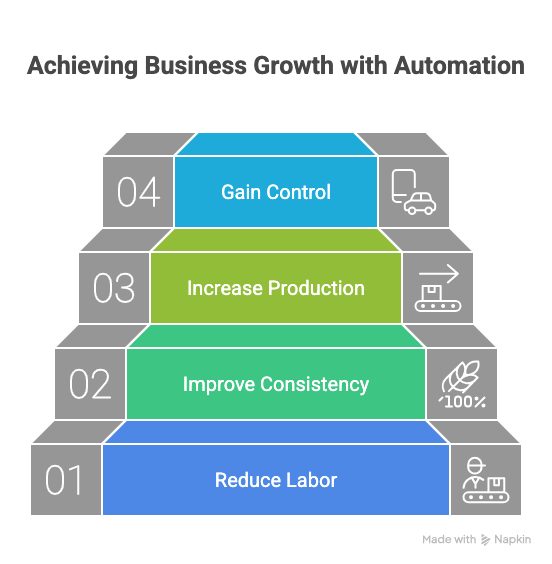

The semi-automatic makhana flavoring machine for small business is a smart move for small and mid-sized processors. It fits right into your current makhana machine setup without slowing things down or requiring major changes. The system controls how much slurry goes in, lets you adjust semi-automatic makhana flavouring machine speed, and handles batch sizes that match your production. You get a consistent, even semi-automatic makhana coating machine without extra labor or constant tweaking.

Compared to hand-mixing, it saves time, cuts seasoning waste, and protects your product from breakage. That consistency matters. It builds buyer confidence and makes sure each batch looks and tastes the same, which is exactly what retailers and exporters expect. Margins improve because you lose less and produce more without overspending on labor or production costs. If your flavoring still relies on trial-and-error, then makhana flavoring equipment for startups gives you control, reliability, and retail-ready results.

Essential Specifications: Semi-Automatic Makhana Flavoring Machine

| Detail | Value |

| Price | ₹2.5 lakh (approx.) |

| Daily Capacity | 100–300 kg |

| Labor Required | 1 operator |

| Batch Size | 10–50 kg |

| Cleaning Time | 10–15 minutes |

| Space Needed | 6×4 ft area |

| Power Supply | Single-phase |

Why ₹2.5 Lakh Is a Smart Investment

Let’s be honest, it takes more people, wastes more mix, and still leaves you guessing on consistency. A semi-automatic makhana flavoring machine for small business solves that in one move. You go from 3–4 workers to just one. Coating time drops by half. Every batch tastes and looks the same. That’s the kind of reliability buyers trust.

What this really means is you can scale from 150 to 300 kg a day without hiring more people or risking your quality. It’s a simple upgrade with serious impact, and it gives small processors the control they’ve been missing.

The Payoff Of A Semi-Automatic Makhana Flavoring Machine

-

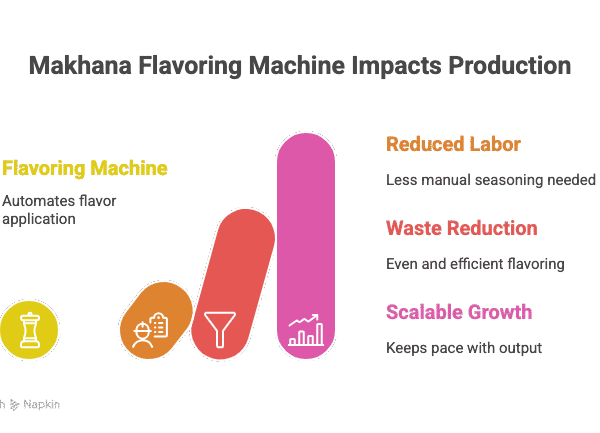

Automates flavor mix and application

Even if you are running spicy, herby, or sweet, this industrial makhana machine handles it. Changeovers are fast, which makes SKU switching smooth. Manual seasoning is one of the messiest, most inconsistent parts of the process. This food-grade flavoring machine for makhana takes that off your plate. It controls how much flavor goes in and how it spreads across each batch, so you’re not guessing, tossing, or redoing.

-

Cuts labor needs and brings down daily costs

Let’s break it down: what used to take three or four people can now be handled by one. That’s not just a staffing win, it’s a cleaner, more focused workflow. The rest of your team can move to packing or prep without slowing down the line. You waste less seasoning and protect your margins.

-

Reduces waste and improves flavor use

Food-grade stainless steel, compact enough to drop into your line without rewiring your whole setup. Seasoning is expensive, and most of it gets wasted with hand-coating clumps, spills, and overuse. This makhana flavoring equipment for startups applies flavor evenly and efficiently. You end up using less mix for the same (or better) taste. That’s money saved on every batch.

-

Sets you up for real growth

What this really means is you are not stuck anymore. Even if you are doing 100 or 300 kg a day, the food-grade flavoring machine for makhana keeps pace. You don’t need a bigger team, just a smarter process. And once your output looks retail-ready, new markets start to open up.

Foodsure Machines Drive The Shift To Smarter Flavoring

The Foodsure Machines semi-automatic makhana flavoring machine is a smart upgrade for small makhana machine. It handles slurry dosing and semi-automatic makhana flavoring drum speed automatically, so every batch gets a clean, even coating with no breakage. You cut down on seasoning waste, reduce labor, and boost consistency, all without overhauling your setup. It’s a simple way to scale up without losing control of quality. Every Delay Has a Cost—Here’s the Fix That Stops the Leak.

For more info contact Foodsure Machines now +91-8826663121

The Fix That Stops the Leak!

For more info, contact Foodsure Machines by call or email.

FAQ

1. What problem does the ₹2.5 lakh semi-automatic flavoring drum solve?

Manual coating is messy and inconsistent. This machine gives you clean, even flavoring with less breakage, so your makhana tastes better, looks uniform, and gets accepted by more buyers.

2. How does this machine benefit small makhana producers?

It turns a slow, tiring process into a fast, one-person job. It will help you to save on labor, reduce flavor waste, and double your batch speed. That means more output, more consistency, and better odds of getting into high-paying markets.

3. Why is this upgrade important for accessing modern retail and export markets?

Because mostly buyers expect from your product consistency, hygiene, and reliability and this machine helps you deliver exactly that. You hit higher quality standards without needing a massive setup, which means better prices, fewer rejections, and more room to grow.

4. How does replacing manual coating with a semi-auto flavor drum save ₹2.5 lakh in production?

Manual coating takes more people, more time, and often wastes more seasoning. A semi-automatic flavor drum fixes all three. It spreads the flavor evenly, every time, with less manual effort and no overuse of ingredients. That kind of control can easily save ₹2.5 lakh a year in labor and raw material losses.

5. What license is required for a Semi-Automatic Makhana Flavoring Machine business?

You need an FSSAI registration/license to legally operate a makhana flavoring and processing setup.

6. How to sell makhana processed with a Semi-Automatic Makhana Flavoring Machine?

Pack the flavored makhana hygienically, label it as per FSSAI norms, and sell via retail, wholesale, or online channels.

7. Who is the biggest producer of makhana relevant to machine buyers?

Bihar is the largest makhana-producing region, making it a major market for flavoring machines.

8. Why is machine-processed phool makhana costly?

Premium raw material and value-added processing like automated flavoring increase the final product cost.

9. How to sell flavored food made using a Semi-Automatic Makhana Flavoring Machine without an FSSAI license?

Legally, you cannot sell any processed food including makhana, without at least basic FSSAI registration.

10. Who is eligible for an MD-42 license when using a makhana flavoring machine?

Any food business operator involved in manufacturing flavored or processed foods that fall under the MD-42 category can apply.

11. What is the 30/30/30 rule for restaurants using makhana machines?

It’s a guideline suggesting 30% food cost, 30% labor cost, and 30% overheads for balanced restaurant operations.

12. Is an FSSAI license mandatory for running a Semi-Automatic Makhana Flavoring Machine unit?

Yes, FSSAI registration or licensing is mandatory for all processing units.