Makhana has long been part of traditional Indian diets, and today it’s becoming a global superfood. India proudly leads the makhana production, contributing over 90% to the global supply, with Bihar alone producing over 80%. Known for its nutritional value, makhana, also known as fox nut or lotus seed, is packed with protein, calcium, and antioxidants, making it a popular choice among health-conscious consumers globally. But behind every high-quality pack of makhana lies a well-structured makhana processing system, and that’s where the role of Makhana Machines Companies in India becomes necessary. These companies are taking innovation in processing technology, ensuring every batch of makhana meets the highest standards of quality, hygiene, and efficiency.

If you’re a food entrepreneur, agro-industrialist, or someone planning to start a makhana processing unit, Foodsure Machines is your trusted partner in the makhana industry. We offer you the latest roasting, grading, and packaging equipment made for the consistent quality of makhana.

1. Foodsure Machines – Makhana Machine In India

Great list! Foodsure Machines really stands out for modern and efficient solutions.

Foodsure Machines provides advanced makhana processing equipment that is designed for efficiency, quality, and scalability in India’s growing snack market. Our makhana machines are a combination of semi-automatic and fully automatic, which gives you automated roasting, grading, flavoring, and packaging.

2. S K Engineering, Bihar

Located in the heart of makhana production — Bihar, S K Engineering has made a mark in providing makhana popping and grading machines. They offer customized setups for small to medium-scale units and are known for after-sales support.

USP: Local expertise, cost-effective, ideal for startups.

3. Hytek Food Equipment, Haryana

Hytek provides a wide range of food processing machines, including makhana roasters and poppers. Their machines are robust and are often used in industrial-scale setups.

USP: Durable machines, great for industrial use.

4. Tooltech Engineering, Gujarat

Known for quality control and innovation, Tooltech offers both traditional and modern makhana processing units. They also offer training for machine operation.

USP: Strong technical support and modern designs.

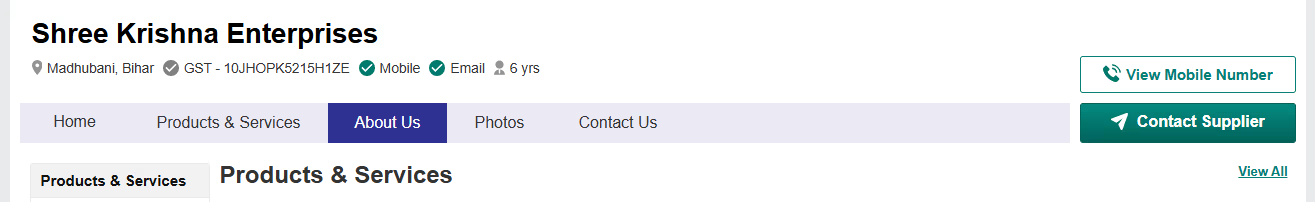

5. Shree Krishna Industries, Madhubani

They have become a go-to option for budget-friendly makhana machines in Bihar. Their machines are simple to operate and perfect for village-level entrepreneurs.

USP: Local pricing, simple setup, and rural entrepreneur-friendly.

Government Support & Subsidies

- PMEGP (Prime Minister’s Employment Generation Programme)

- Mudra Loan

- FME Scheme (Food Processing Ministry)

Some companies even assist with documentation for subsidies and MSME quotations.

Ready To Start Your Makhana Business?

The rise in health-focused snacking has placed Makhana at the center of India’s food innovation space. For entrepreneurs, it’s a golden opportunity to start or grow a profitable business, and choosing the right Makhana Machine Company in India is your first step.

When selecting a company, don’t just go by price. Look at support, quality, user experience, and training. A good machine setup can run smoothly for years and help you scale your business across India and even for exports.

Setting up a Makhana processing unit or want company recommendations?

Send us your query in the comments or contact us