Small-scale village cooperatives face real issues with traditional roasting: uneven batches, high fuel use, and high product waste. These issues are already tight margins and make it hard to grow. But with the food-grade machine for cooperatives, the results were seen immediately. The fuel-efficient roaster for the co-op immediately reduced fuel costs. Burnt batches became rare. And product quality improves, giving them a better product to sell at higher prices. With precise heat control and consistent output, they could finally rely on every batch. Let’s be clear: you don’t need a massive upgrade or a big factory setup. You just need energy-saving roasting equipment co-operative for your work, which will help you scale. One smart shift in your roasting setup can improve quality, reduce costs, and open up new markets.

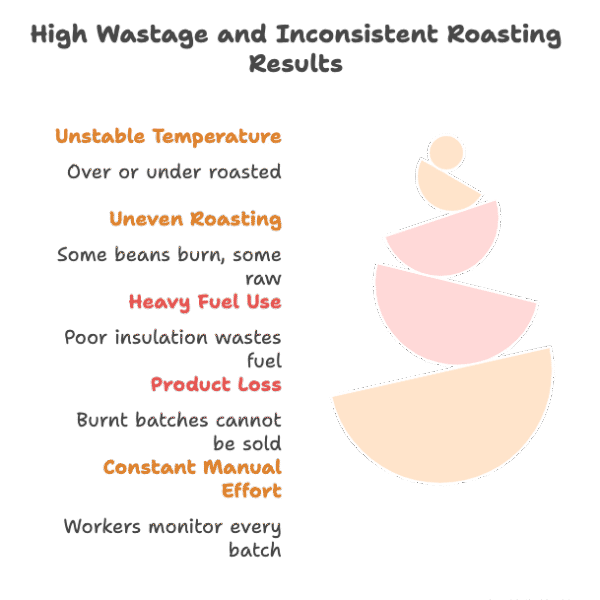

The Challenge: High Wastage And Inconsistent Results In Traditional Roasting

Many small village roasters still use drum or pan roasters powered by open flames or old gas units. These setups bring real issues:

- Unstable temperature control: Operators adjust heat by feel, so batches often come out over-or under-roasted.

- Uneven roasting: Some beans burn, others stay raw. There is no consistent heat spread.

- Heavy fuel use: Poor insulation and inefficient heat transfer burn through fuel fast.

- Product loss: Burnt or uneven batches can’t be sold at full price or at all.

- Constant manual effort: Workers have to monitor every batch closely just to avoid spoilage.

What’s really happening: Every one of these issues chips away at profits. Quality goes down, fuel-efficient roaster for co-op costs go up, and market-ready product becomes harder to guarantee. If buyers pay for consistency, this kind of system is working against you.

The Solution: Investing In An Automated, High-Efficiency Roaster

The village roaster upgrade benefits cooperatives decided to replace their old roasting setup with the food-grade machine for cooperatives, designed for small-scale roaster fuel savings. It wasn’t just a new machine; it changed the way they worked. Let’s see how it helped.

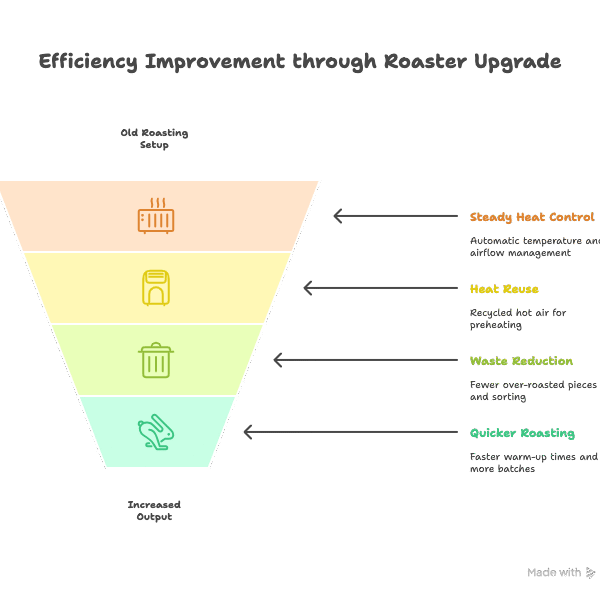

1. Steady Heat Control Without Trial & Error

Older machines need constant attention. This roaster upgrade benefits the co-operative by using automatic controls to handle temperature and airflow properly. Even stable heat keeps batches from burning or staying underdone. Saved settings make it easy to repeat the same roast each time. That means fewer manual mistakes, since the system handles key parts of the process.

2. Reusing Heat to Lower Fuel Use

Most older machines lose a lot of heat. This one reuses it. Recycled hot air helps preheat new batches instead of escaping. Thick insulation keeps heat from leaking out. Better airflow spreads heat more evenly.

3. Less Waste, More Product Ready to Sell

Even roasting meant fewer over-roasted pieces, extra sorting, or repeat work, which saved time and effort. More of each batch could be sold. Their waste dropped from 12% to under 5%, which made a noticeable difference.

4. Quicker Roasting, More Output

The food-grade machine for cooperatives heats up in about 7 minutes. The old one needed 20 to 30. Faster warm-ups mean less waiting and less fuel burned doing nothing. They could roast several batches a day without stopping. Operators had more time to focus on the final output.

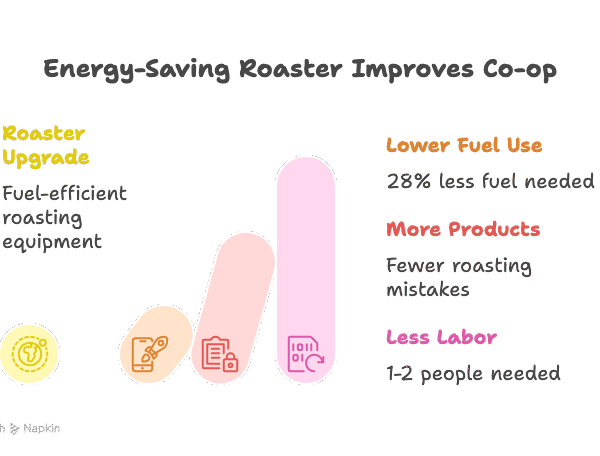

What The Cooperative Gained From One Change

All these energy-saving roasting equipment co-operative changes didn’t just look good on paper; they made a real difference in day-to-day operations. The food-grade machine for cooperatives began to see clear improvements where it mattered most: fuel use, output, staffing, and sales. Take a look at what changed after the upgrade: Lower fuel use from a fuel-efficient roaster for co-op. By holding onto more heat and using it again, they used 28% less fuel. That saved them a lot of money each year on gas and charcoal.

More sellable products with fewer roasting mistakes, more products were ready for sale, and buyers were willing to pay better prices and had less dependence on labor. They only needed 1–2 people for roasting instead of 4–5, and others could focus on packing or higher-value work with better buyer interest. With steady product quality, they started hearing from larger buyers and even got interest from exporters.

Key Takeaways: What To Look For When Upgrading Your Roaster

If you run a small-scale roaster fuel savings setup, whether it’s coffee, makhana, or nuts, these are the kinds of changes that can make your work more reliable. When fuel-efficient roaster for co-op costs and product loss are high, even a single energy-saving equipment can make a big difference. What this really shows is:

| Feature | Specification |

| Capacity | 30–100 kg per batch |

| Drum Size | 700–1000 mm dia × 1200–1500 mm length |

| Power | 1.5–3 kW, 3 Phase, 415V |

| Speed Control | VFD-based adjustable rotation |

| Coating System | Oil/slurry spray + dry spice dosing |

Smarter Roasting Starts With Foodsure Machines

Foodsure Machines gives the food-grade machine for cooperatives, exactly what they need to roast better and waste less. Our automated tunnel roasters are built to keep heat steady, cut fuel use, and take the guesswork out of the process. The system recirculates heat efficiently and holds the temperature where it needs to be. This means small processors finally save fuel, reduce labor, and gain control.

Want to know if this roster is right for your unit?!

Reach out to us anytime via call or email.

FAQ

1. How did the roaster upgrade reduce the burn rate in the village co-op?

The old system relied on manual adjustments, which often led to overheating. The new roaster uses automated controls to hold temperature and airflow steady, so every batch roasts evenly. No more burnt kernels. No more second-guessing. That one change cut down product loss in a big way.

2. What impact did the roaster upgrade have on fuel costs?

Heat used to escape through thin walls and open vents. Now, it’s recycled back into the process. Add better insulation, and the roaster holds onto heat instead of wasting it. Fuel use dropped by nearly 30%. That’s less money spent on gas and charcoal—month after month.

3. Why is this upgrade important for small-scale processors like the Village Cooperative?

Because it solves three big problems at once: inconsistent quality, high fuel use, and labor overload. With better control and less waste, small units can sell more, work easier, and reach buyers who demand uniform products. What this really means is better margins, better markets, and room to grow.

4. What is a Food-Grade Machine for Cooperatives called?

A Food-Grade Machine for Cooperatives is called a certified hygienic processing unit designed for shared food production.

5. What are QA and QC for a Food-Grade Machine for Cooperatives?

QA ensures the machine meets safety standards, while QC checks its consistent performance during cooperative operations.

6. What are 5 examples of cooperative uses for a Food-Grade Machine?

Mixing, grinding, packaging, drying, and extruding operations for shared food production.

7. What machine tests food quality in cooperatives?

A food-grade testing unit like a moisture analyzer or metal detector ensures product safety.

8. What is F&B equipment in cooperatives?

F&B equipment refers to all food-grade machines used for safe, hygienic processing in shared facilities.

9. What are the three types of food production systems for cooperatives?

Batch processing, continuous processing, and semi-automatic production.

10. What are 10 tools used with Food-Grade Machines for Cooperatives?

Scales, thermometers, mixers, grinders, sealers, knives, trays, sieves, timers, and sanitizers.

11. What is a Food-Grade Extruder Machine for Cooperatives?

It’s a machine that shapes food ingredients through controlled heat and pressure for shared production.

12. How much does a Food-Grade Extruder for Cooperatives cost?

Food-grade extruders range from a few thousand dollars to over $50,000 depending on size and capacity.